Preparation method of meta-aramid insulating paper for suppressing space charge accumulation

A space charge and insulating paper technology, applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve problems affecting insulation performance, achieve the effects of increasing recombination probability, inhibiting space charge accumulation, and reducing motion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

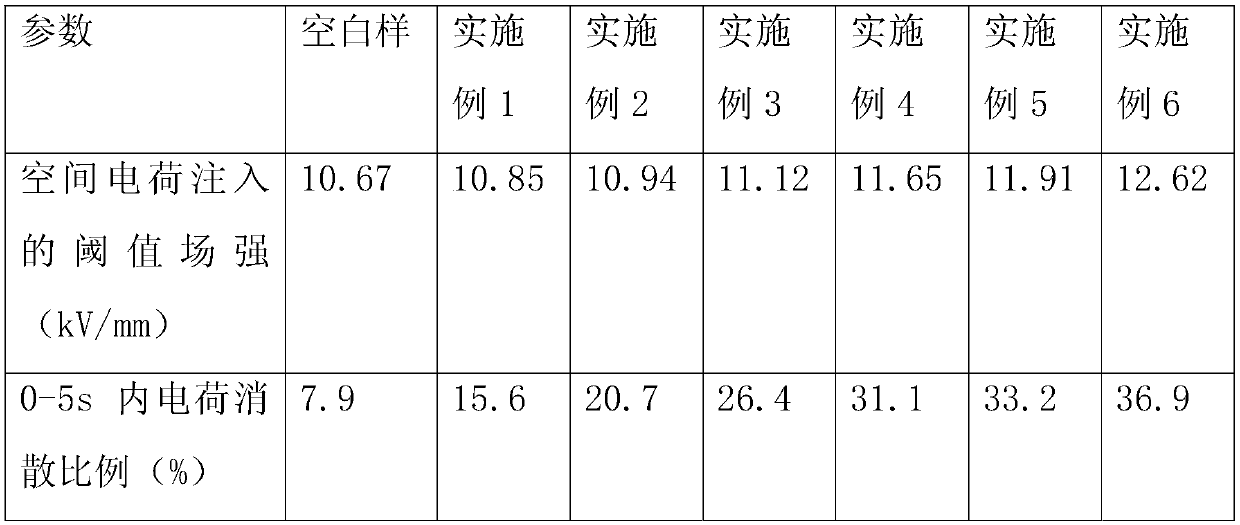

Examples

preparation example Construction

[0020] The preparation method of the meta-aramid insulating paper that suppresses the accumulation of space charges in this embodiment comprises the following steps:

[0021] a. After mixing meta-aramid chopped fiber and meta-aramid fiber pulp, disperse, disperse, and beat to prepare pulp mixed solution;

[0022] B, the pulp mixed solution that makes in the step a and nanometer TiO 2 After the deionized aqueous solution is mixed and decomposed, the nano-TiO is prepared by beating 2 Modified meta-aramid pulp;

[0023] C, the nano-TiO that makes in the step b 2 Modified meta-aramid pulp is paper-formed to produce meta-aramid insulating paper that inhibits space charge accumulation;

[0024] Nano TiO 2 Modification of meta-aramid insulating paper can make the meta-aramid insulating paper which has excellent performance suppress the accumulation of space charge, making it suitable for strong electric field environment. Nano-TiO 2 The reason why it can be used for the modific...

Embodiment 1

[0038] 1. Nano-TiO 2 Preparation of deionized aqueous solution: take nano TiO at a weight ratio of 1:400 2 Particles (with a particle size of 35nm) were mixed with deionized water to prepare a suspension, and then the suspension was placed at a temperature of 50°C and ultrasonically treated for 15 minutes to obtain dispersed nano-TiO 2 Deionized aqueous solution;

[0039] 2. Preparation of pulp mixed solution:

[0040] (1) Mixing and dispersion treatment: After mixing meta-aramid chopped fibers and meta-aramid fiber pulp at a weight ratio of 1:0.15, ultrasonic dispersion is carried out in deionized water using an ultrasonic dispersing processor model FS-1800N Processing, in the process of ultrasonic treatment, the frequency set by the processor is 20kHZ, the power is 1200W, the temperature during ultrasonication is 50°C, and the dispersion time is 10min;

[0041] (2) Deflagging treatment: after the dispersing treatment, use a fiber dissociator of model IMT-SJ0104 to perform...

Embodiment 2

[0050] 1. Nano-TiO 2 Preparation of deionized aqueous solution: take nano TiO at a weight ratio of 1:400 2 Particles (with a particle size of 32nm) were mixed with deionized water to prepare a suspension, and then the suspension was placed at a temperature of 60°C and ultrasonically treated for 10 minutes to obtain dispersed nano-TiO 2 Deionized aqueous solution;

[0051] 2. Preparation of pulp mixed solution:

[0052] (1) Mixing and dispersion treatment: After mixing meta-aramid chopped fibers and meta-aramid fiber pulp at a weight ratio of 1:0.20, ultrasonic dispersion is carried out in deionized water using an ultrasonic dispersing processor model FS-1800N Processing, in the process of ultrasonic treatment, the frequency set by the processor is 20kHZ, the power is 1200W, the temperature during ultrasonication is 60°C, and the dispersion time is 15min;

[0053] (2) Deflagging treatment: after the dispersing treatment, the fiber disintegrator model IMT-SJ0104 is used for d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com