A metal hydride surface hydrogen permeation resistance layer and its preparation method

A permeable layer and hydride technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of weak bonding between the coating and the hydride substrate, difficulty in implementing a hydrogen barrier film, and incompact film layer Integrity and other issues, to achieve excellent hydrogen barrier performance, moderate thickness, dense film effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

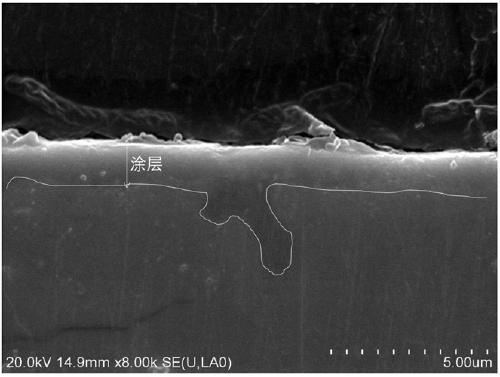

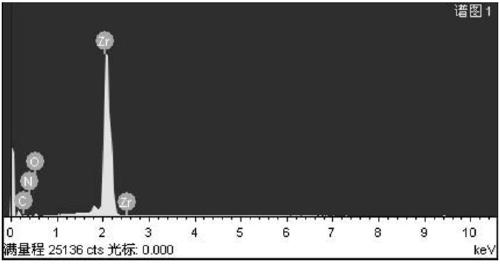

[0033] 1. Degrease, clean and polish the surface of Φ30mm×30mm zirconium hydride, and the H / Zr of zirconium hydride is 1.65.

[0034] 2. Loading and heat-resistant glass packaging

[0035] ① Weigh 1.5g urea with a balance;

[0036] ② Put urea and zirconium hydride in a high-temperature-resistant glass tube, vacuum seal, and the pressure inside the high-temperature-resistant glass tube is 1×10 - 5 Pa.

[0037] 3. Preparation of hydrogen-resistant permeable layer containing carbon, nitrogen and oxygen

[0038] Put the encapsulated glass tube in a temperature-controlled tube furnace, raise it from room temperature to 500°C at a rate of 300°C / h, keep it at 500°C for 100 hours, then cool it down to 300°C at a rate of 600°C / h, and then cool it naturally to room temperature to obtain a hydrogen permeable barrier layer containing carbon, nitrogen and oxygen.

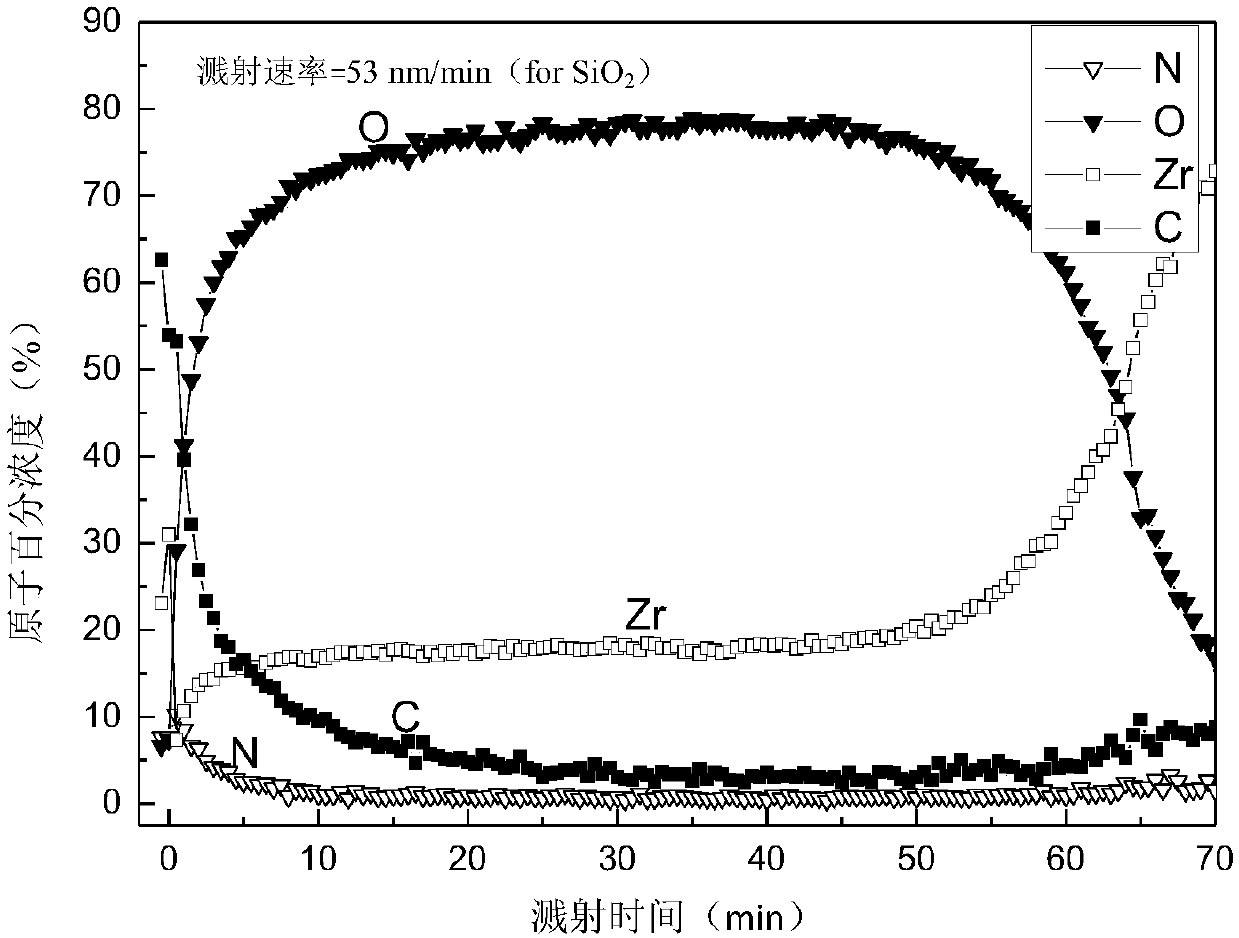

[0039] The surface AES analysis of the hydrogen barrier permeation layer adopts the PHI-700 nanometer scanning Auger syst...

Embodiment 2

[0042] 1. Degrease, clean and polish the surface of Φ30mm×30mm zirconium hydride, the H / Zr of zirconium hydride=1.85.

[0043] 2. Loading and quartz tube packaging

[0044] ① Use a balance to weigh 5g of acrylamide;

[0045] ②Place acrylamide and zirconium hydride in a quartz tube for vacuum packaging, the pressure inside the quartz tube is 1×10 -3 Pa.

[0046] 3. Preparation of hydrogen-resistant permeable layer containing carbon, nitrogen and oxygen

[0047] Put the packaged quartz tube in a temperature-controlled tube furnace, raise it from room temperature to 400°C at a rate of 600°C / h, keep it at 400°C for 200h, and then raise it from room temperature to 500°C at a rate of 300°C / h , kept at 500° C. for 100 h, and finally cooled naturally in the furnace to room temperature to obtain a hydrogen-resistant permeable layer containing carbon, nitrogen and oxygen, and its hydrogen permeability level is equivalent to that of the carbon, nitrogen and oxygen-containing coating i...

Embodiment 3

[0049] 1. Degrease, clean and polish the surface of Φ20mm×20mm zirconium hydride, and the H / Zr of zirconium hydride is 1.9.

[0050] 2. Loading and stainless steel pipe welding and sealing

[0051] ① Take 5g of ammonium carbonate with a balance;

[0052] ②Put the ammonium carbonate and zirconium hydride in the stainless steel tube, argon arc welding, the pressure inside the stainless steel tube is 101kPa.

[0053] 3. Preparation of hydrogen-resistant permeable layer containing carbon, nitrogen and oxygen

[0054] The stainless steel tube is placed in a temperature-controlled tube furnace, raised from room temperature to 200°C at a rate of 300°C / h, and kept at 200°C for 1 hour; then raised to 500°C at a rate of 100°C / h, and kept at 500°C for 50 hours ; After that, the temperature was raised to 600°C at a rate of 10°C / h, and kept at 600°C for 200h; then the temperature was lowered to 300°C at a rate of 600°C / h, and then naturally cooled to room temperature to obtain a hydrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com