Sheet metal forming method and device based on laser shock wave and vibration technology

A metal sheet and shock wave technology, applied in sheet forming, based on the field of half-mold forming sheet, can solve the problems of low precision and large springback, and achieve the effect of improving forming efficiency, increasing plastic deformation and small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

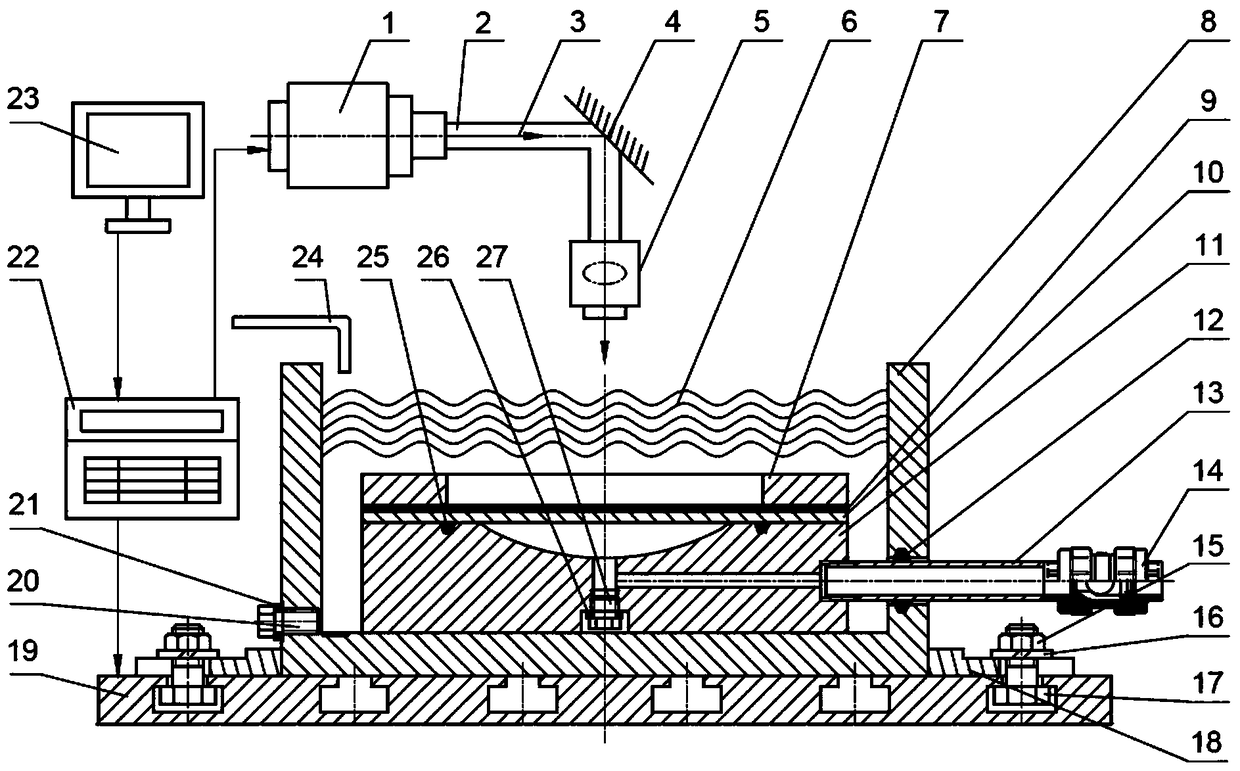

[0030] The method and device of the present invention will be further described below by forming a 0.2 mm thick 2024 aviation aluminum alloy plate in conjunction with the accompanying drawings.

[0031] The specific steps of the sheet metal forming method based on laser shock wave and vibration technology provided by the present invention are as follows:

[0032] (1) The metal plate 10 is a 0.2mm thick 2024 aviation aluminum alloy plate, wipe the upper surface of the metal plate 10 with acetone, and after drying, coat a layer of black paint with a thickness of 0.10mm on the metal plate 10 upper surface As an energy absorbing layer 9 for laser light.

[0033] (2) The O-type second sealing ring 25 with cross-sectional diameter φ 3.5mm is installed in the annular sealing groove of the mold 11 whose groove depth is 3.2mm, and the metal plate 10 coated with the energy absorbing layer 9 on the upper surface It is fixed on the mold 11 by the binder plate 7 with the middle hole.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com