Mud scraping device in sewage treatment equipment

A technology of sewage treatment equipment and water spraying device, which is applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of reducing sludge dewatering efficiency, short vibration time, and affecting the time of batch sludge filtration. , to achieve the effect of easy automatic cleaning, efficient cleaning, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

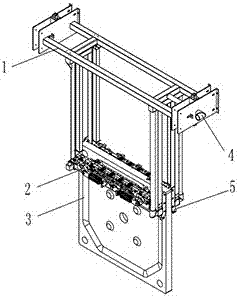

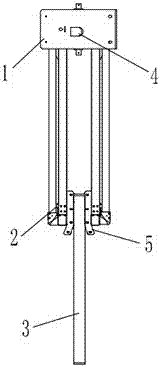

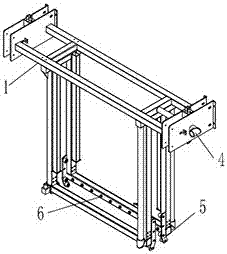

[0033] According to attached figure 1 and 2 It can be seen that the present invention is specifically a mud scraping device in sewage treatment equipment, which specifically includes a lifting frame 1 and two sets of mud scraping devices 2 located at the lower end of the lifting frame 1, wherein the lifting frame 1 is a frame structure, driven by a beam and located in the middle of the beam Two sets of support frames are suspended, and two sets of mud scraping devices 2 are arranged below the two support frames. When cleaning, a filter plate 3 is placed between the two support frames, and two sets of mud scraping devices 2 are respectively located on both sides of the vertically placed filter plate 3 to be cleaned. There is also a water spray device 6 on the lifting frame 1, which communicates with the water inlet pipe 4 located on one side of the lifting frame 1, and the water spray device 6 cooperates with the mud scraping device 1 to spray water and clean the filter plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com