Integration solenoid double-layer magnetic film inductor and preparation method thereof

An integrated spiral and tube type technology, applied in the direction of inductors, circuits, electrical components, etc., can solve the problems of high dielectric loss of semiconductor silicon, limited inductance density, and damage to the lower coil, so as to reduce the loss of parasitic capacitance and make the The effect of low cost and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

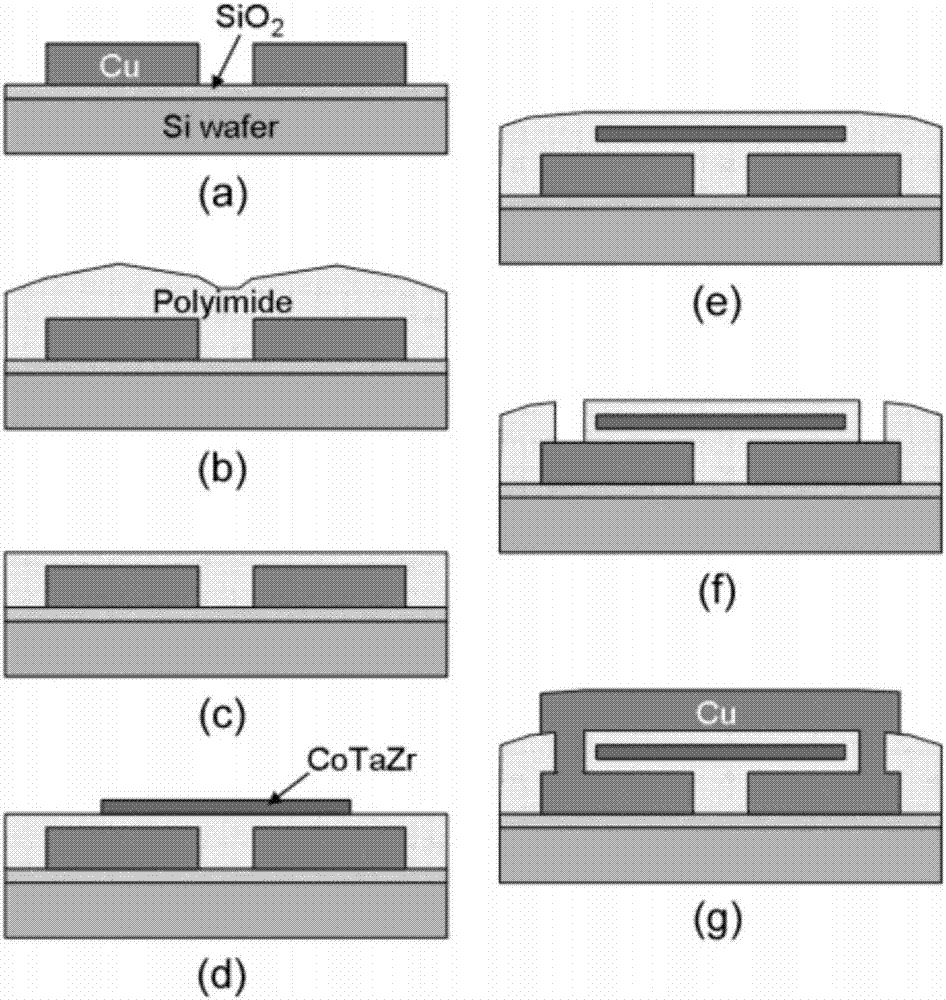

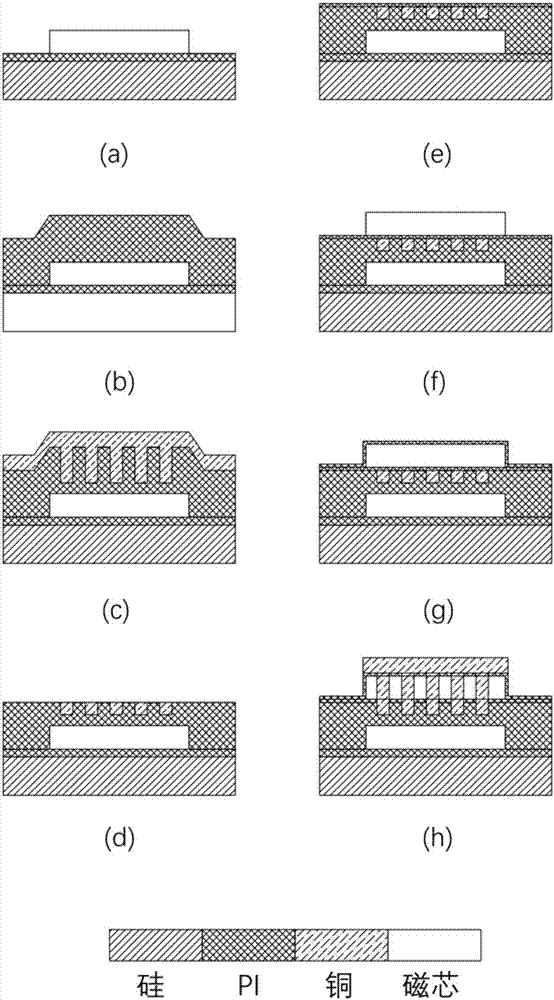

[0030] The present invention will be further described in detail below in conjunction with the drawings and embodiments.

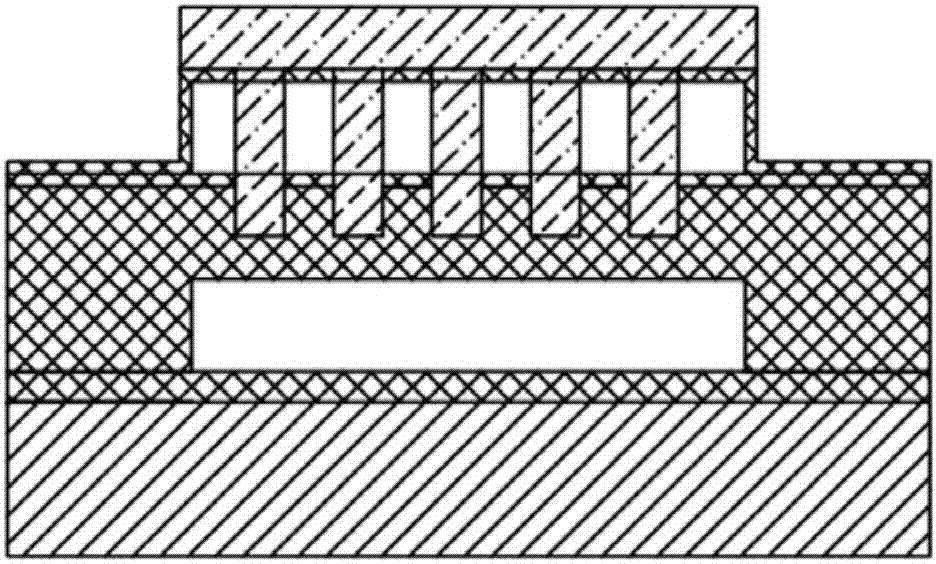

[0031] This embodiment provides an integrated solenoid double-layer magnetic film inductor, the structure of which is as follows figure 2 As shown, it includes a silicon substrate, a lower magnetic core film, a deep buried layer, a lower coil, an upper magnetic core film, an insulating layer and an upper coil; the lower magnetic core film is arranged on the silicon substrate, the lower magnetic core film and the silicon An insulating layer is also provided between the substrates, the deep buried layer covers the silicon substrate and deeply burys the lower magnetic core film, the upper surface of the deep buried layer is also provided with a lower layer coil groove, and the lower layer coil is correspondingly arranged In the lower coil groove; the upper magnetic core film is located on the deep buried layer, the upper coil is located on the upper magnetic cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com