Adapter board with integrated magnetic core inductor and its manufacturing method

An adapter plate and magnetic core technology, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of unsuitable miniaturization applications, large package thickness, large package space, etc., to achieve convenient interconnection, Reduce the packaging volume and reduce the effect of packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be noted that components in the various figures may be shown exaggerated for the purpose of illustration and are not necessarily true to scale. In the various figures, identical or functionally identical components are assigned the same reference symbols.

[0037] Unless otherwise specified, in this application, the quantifiers "a" and "an" do not exclude the scene of multiple elements.

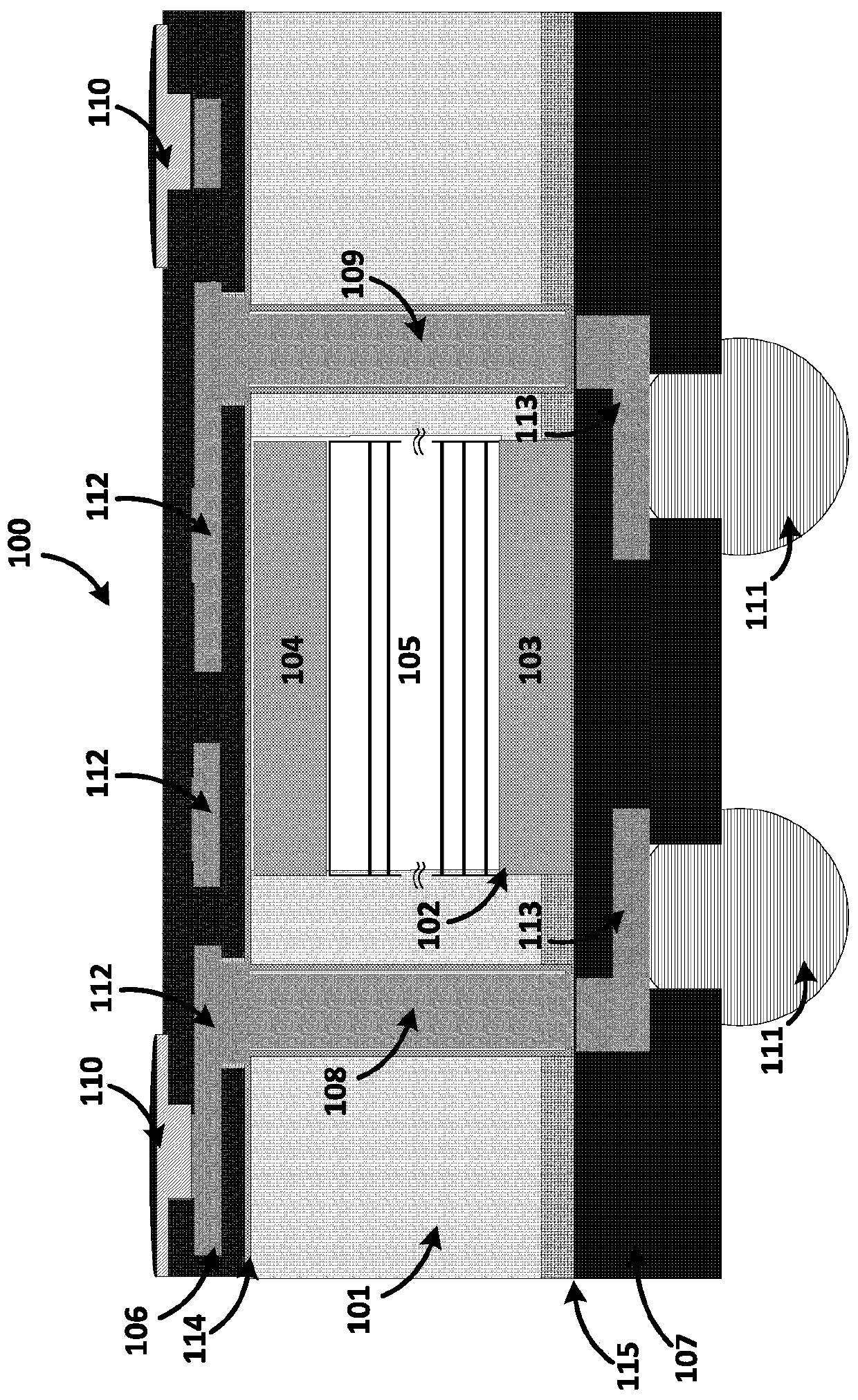

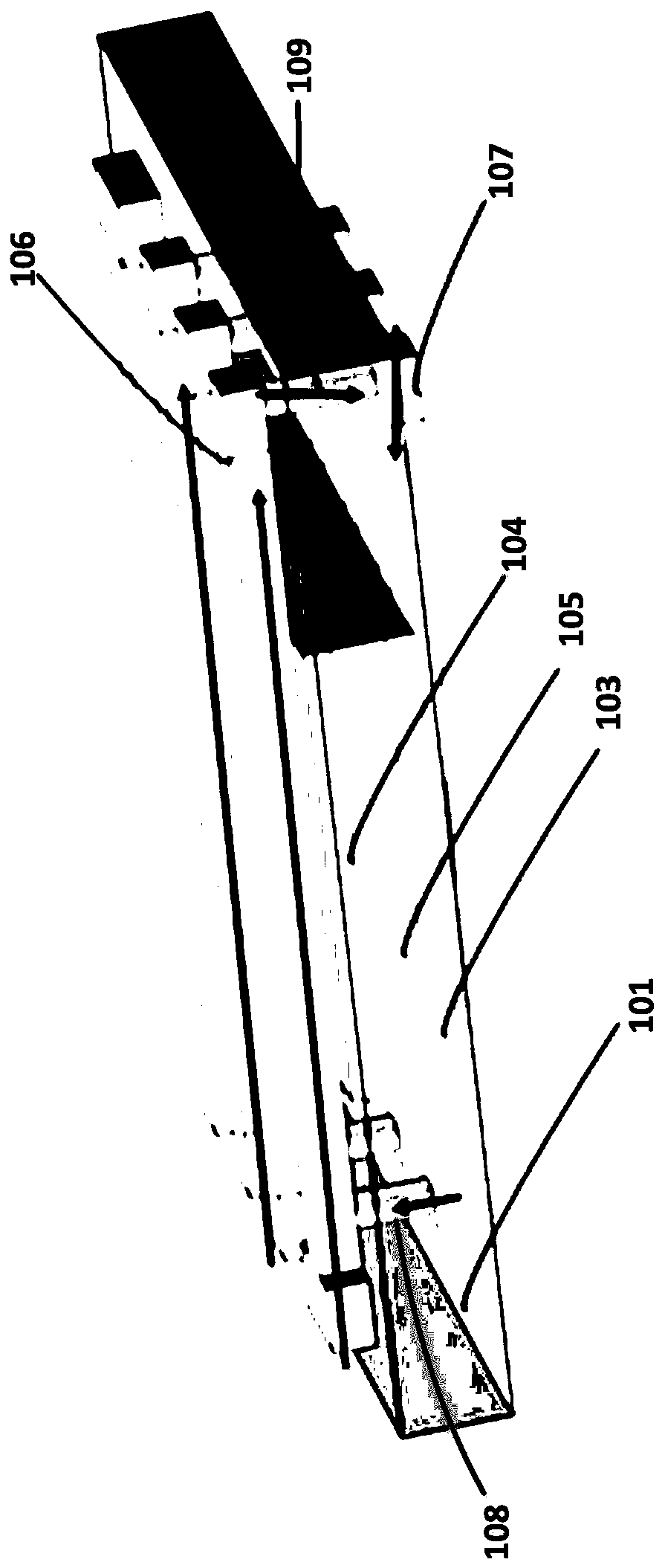

[0038] figure 1 A cross-sectional view of an interposer board 100 integrating magnetic core inductors according to the present invention is shown.

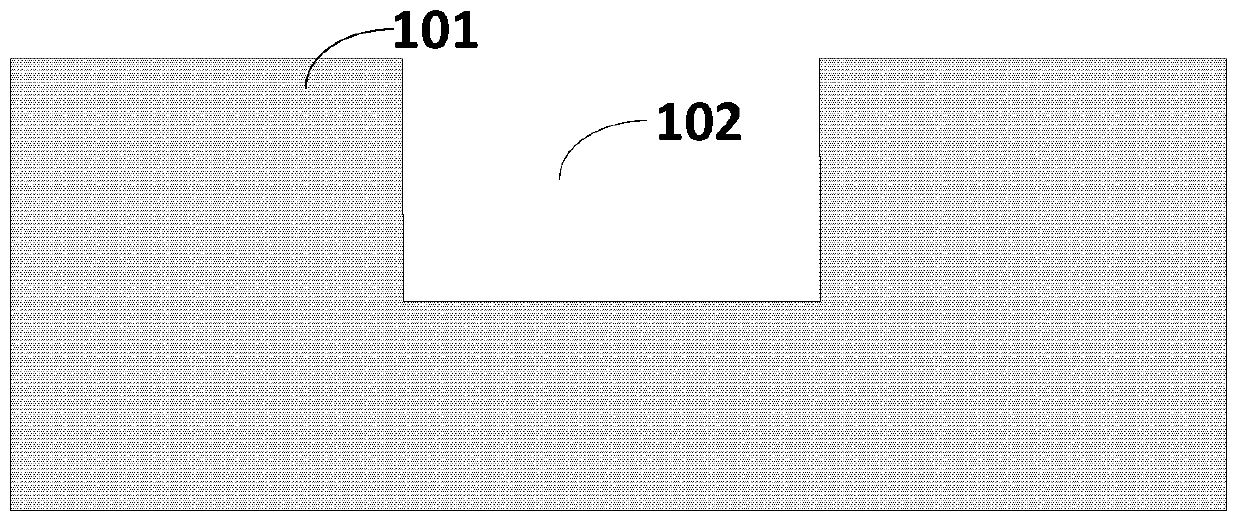

[0039] Such as figure 1 As shown, the interposer 100 with integrated magnetic core inductor has a substrate 101 . Substrate 101 is made of silicon, for example. The substrate 101 has grooves 102 . The groove 102 preferably has a rectangular cross-section, so as to provide a larger lateral area when the thickness of the substrate 101 is low, thereby increasing the inductance value.

[0040] A first insulator 103 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com