A kind of fabrication method of surface plasmon resonance instrument chip

A technology of surface plasmon and production method, which is applied in the field of ion resonance chip production, can solve the problems of sensor chip surface pollution, false positive, and reduce the accuracy of quantitative detection, and achieve easy self-assembly, improved efficiency, and simple preparation method fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

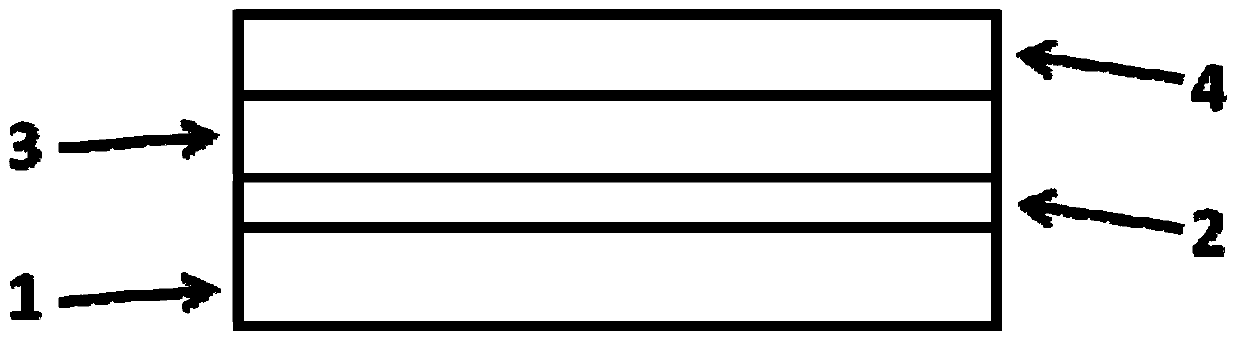

Image

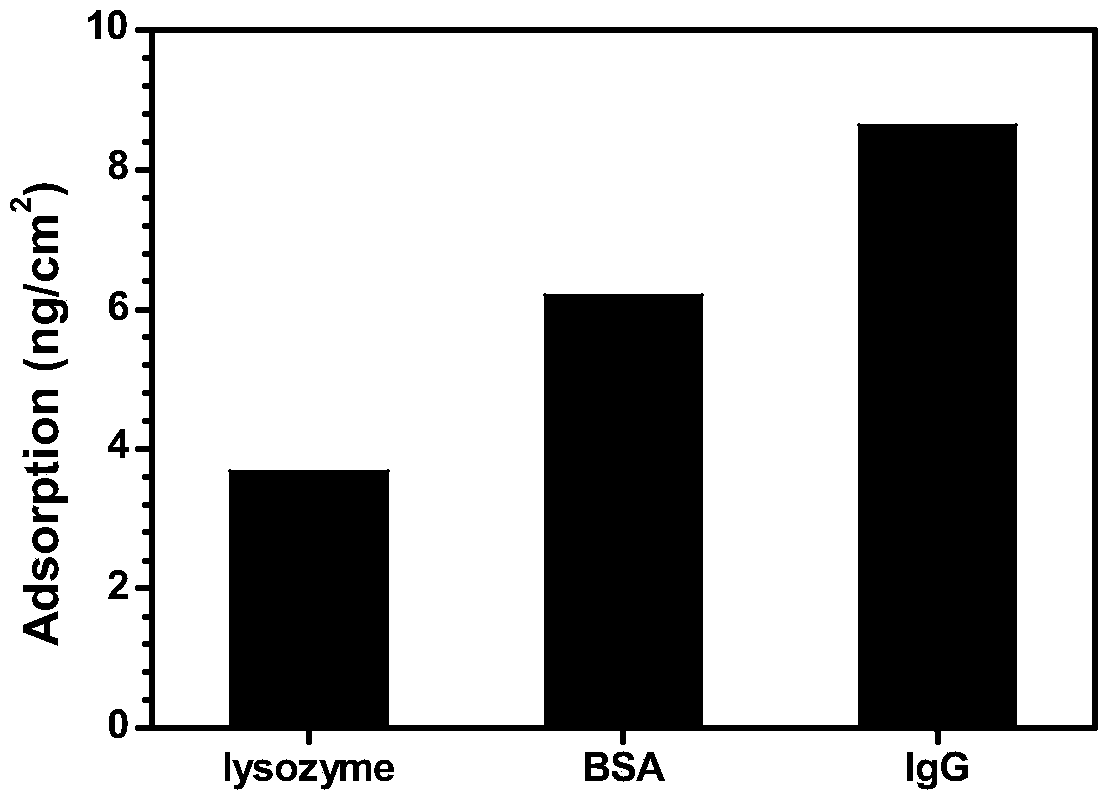

Examples

Embodiment 1

[0028] A method for making a surface plasmon resonance chip based on lysine modification and mucin modification, comprising the following steps:

[0029] a) A 2nm-thick chrome layer and a 48nm-thick gold film were coated on the BK7 glass substrate by electron beam evaporation coating technology, and a bare gold chip was obtained.

[0030] b) Bare gold chip pretreatment: immerse the obtained bare gold chip in a mixed solution of water, 30% concentrated ammonia water and 30% hydrogen peroxide (volume ratio 3:1:1), and soak at 70° C. for 20 minutes. Then take it out, wash it three times with deionized water, and dry it with nitrogen gas for later use.

[0031] c) Pretreatment of mucin solution: prepare 5 mg / mL mucin (secreted from pig stomach) solution with phosphate buffer solution with pH 7.4, and centrifuge the obtained solution at 11000 rpm for 10 minutes to remove aggregated protein.

[0032] d) Mucin modification The SPR chip dried with nitrogen gas was attached to the pri...

Embodiment 2

[0037] A method for making a surface plasmon resonance chip based on lysine modification and mucin modification, comprising the following steps:

[0038] a) A 3nm thick chromium layer and a 47nm thick gold film were coated on the BK7 glass substrate by electron beam evaporation coating technology, and a bare gold chip was obtained.

[0039] b) Bare gold chip pretreatment: immerse the obtained bare gold chip in a mixed solution of water, 30% concentrated ammonia water and 30% hydrogen peroxide (volume ratio 3:1:1), and soak at 80° C. for 10 min. Then take it out and wash it three times with deionized water, and dry it with nitrogen gas for later use.

[0040] c) Pretreatment of mucin solution: 3 mg / mL mucin (secreted from the stomach of pigs) solution was prepared with phosphate buffer solution with a pH of 7.4, and the resulting solution was centrifuged at 9000 rpm for ten minutes to remove aggregated proteins.

[0041] d) Mucin modification: attach the cleaned SPR chip to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com