Novel prefabricated heat preservation and sound insulation floor structure and construction method thereof

A technology for thermal insulation and sound insulation and prefabricated panels, which is applied to floor slabs, building components, building structures, etc., can solve the problems of poor thermal insulation and sound insulation, complex construction procedures, and high costs, so as to reduce the construction period, improve the performance of preventing water seepage, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

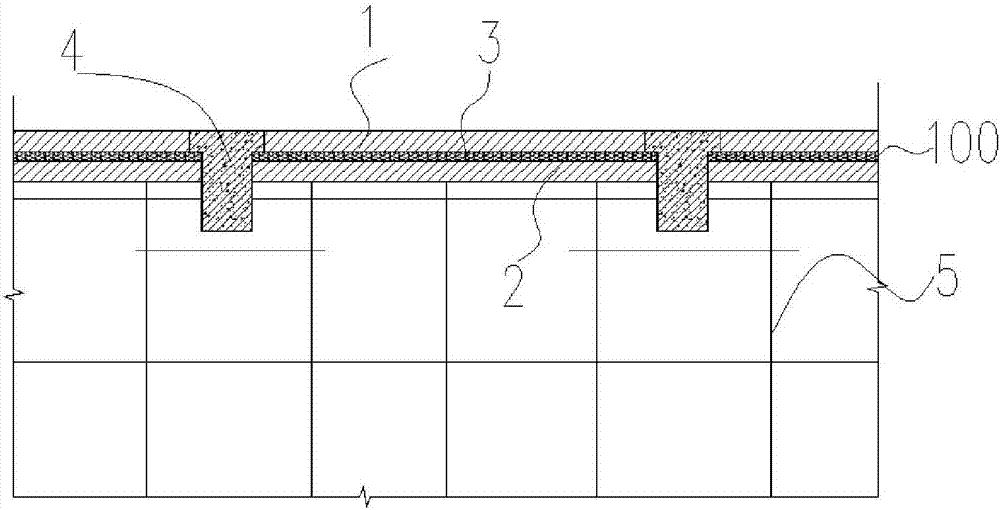

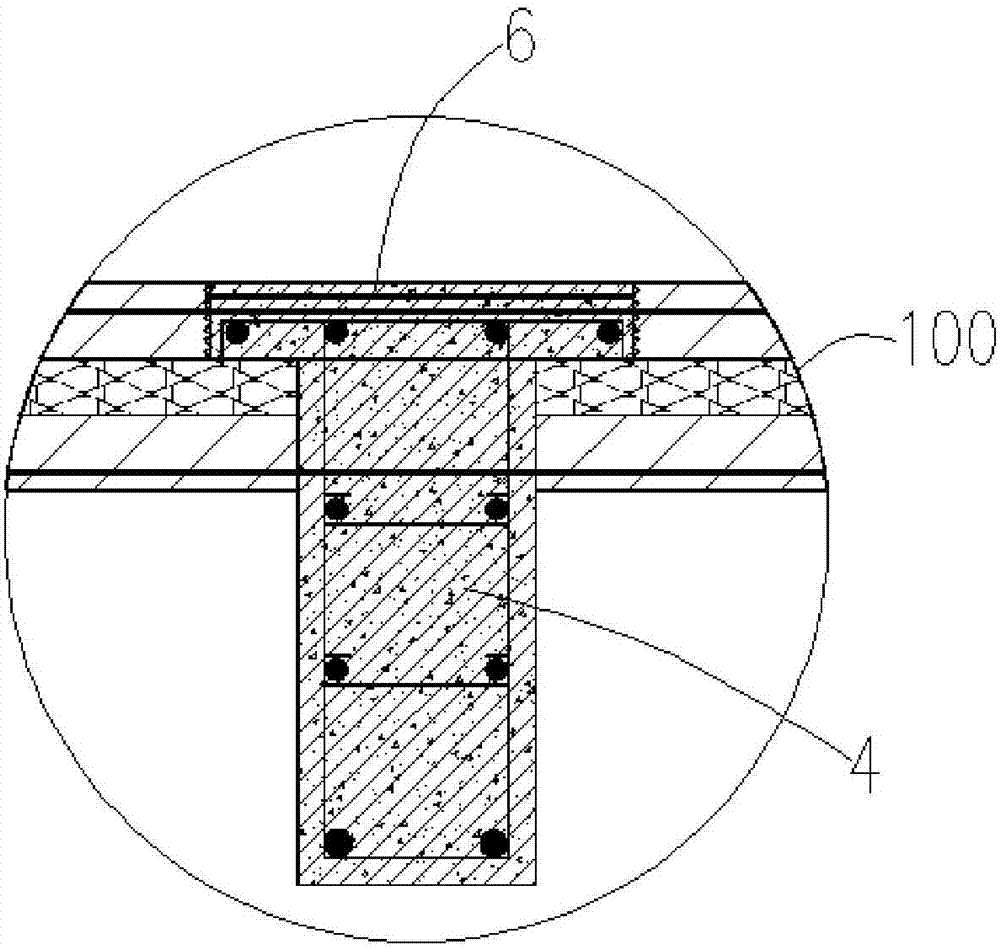

[0015] Such as figure 1 and figure 2 As shown, a new type of prefabricated thermal insulation and sound insulation floor structure, the prefabricated thermal insulation and sound insulation floor is a prefabricated floor, all prefabricated in the prefabrication factory according to the design specifications; The sound insulation board is located between the upper and lower layers of reinforced concrete prefabricated panels, and the thermal insulation and sound insulation panels are centrifugal glass wool boards; The lap joint length of the stressed steel bar at the end of the prefabricated slab is set to 150-200mm; the end of the upper reinforced concrete precast slab of the prefabricated thermal insulation and sound insulation floor slab should be 100 to 150mm shorter than the end of the lower reinforced concrete prefabricated slab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com