Paper pulp and unbreakable packaging box

A pulp and carton technology, applied in the direction of biological packaging, sustainable packaging, natural cellulose pulp/paper, etc., can solve problems such as insufficient strength, rough surface of packaging boxes, and non-conforming to environmental protection concepts, so as to reduce cellulose fluff , Improve the effect of paper quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Pulp embodiment 1 of the present invention: a kind of pulp, its raw material component weight ratio is: pine cellulose 54, agar 3, asparagus 2, lotus bark 7, toughening agent 2, waterproofing agent 3, binder 2; the toughening agent is a mixture of cactus powder and aloe powder; the binder is a mixture of bentonite, magnesium sulfate and starch; debonding agent 2; plasticizer 0.9. Among them, the weight ratio of the raw material components of the detackifier is: propylene carbonate 3.1, glycerol triacetate 1.7, propylene glycol diacetate 2.6; the weight ratio of the plasticizer raw material components is: glycerin 1.2, glucose 1.3, poly Ethylene oxide 1.7.

Embodiment 2

[0021] Pulp embodiment 2: a kind of paper pulp, its raw material component weight ratio is: pine cellulose 56, agar 3, asparagus 5, lotus bark 7, toughening agent 2, waterproofing agent 3, binder 2; The toughening agent is a mixture of cactus powder and aloe powder; the adhesive is a mixture of bentonite, magnesium sulfate and starch; debonding agent 2.7; plasticizer 1.1. Among them, the weight ratio of the raw material components of the detackifier is: propylene carbonate 3.1, glycerol triacetate 1.7, propylene glycol diacetate 2.6; the weight ratio of the plasticizer raw material components is: glycerin 1.2, glucose 1.3, poly Ethylene oxide 1.7.

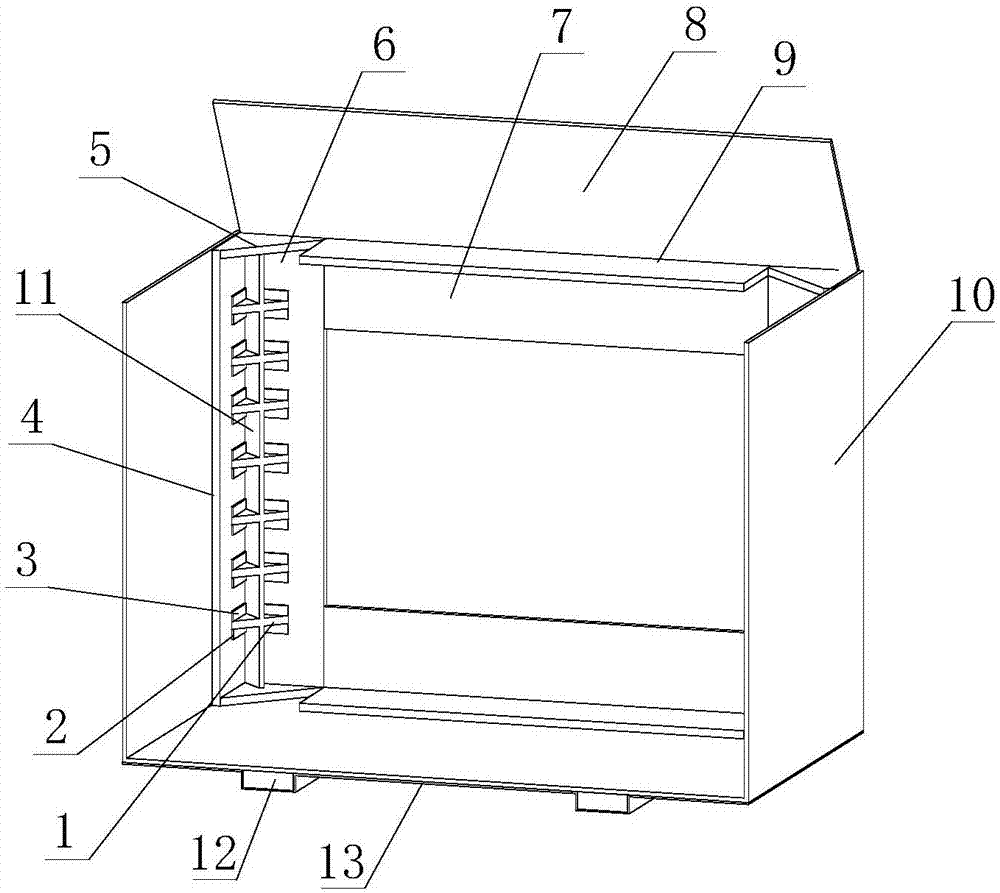

[0022] Packing box embodiment 1: such as figure 1 As shown, a non-breakable packaging box includes a carton body 10, a cover plate 8 is connected to the carton body 10, and it is characterized in that it also includes a connected first folded plate 4 and a second folded plate 6, the first folded plate 4 is pasted on one inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com