Ferrocene-based poly-Schiff base porous polymer, porous polymer material, preparation method and application

A porous polymer, polySchiff base technology, applied in chemical instruments and methods, separation methods, educts, etc., can solve the problems of poor pore size control ability, low adsorption capacity and adsorption capacity, and poor selectivity of porous materials. Large pore volume, simple steps, and the effect of increasing gas adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

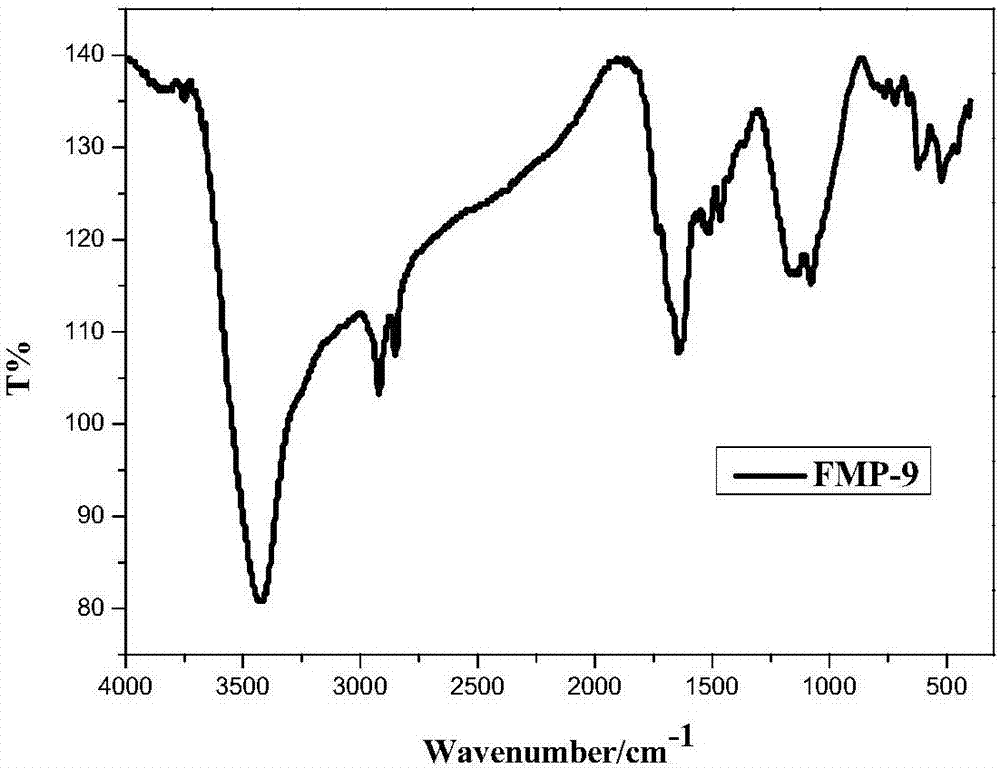

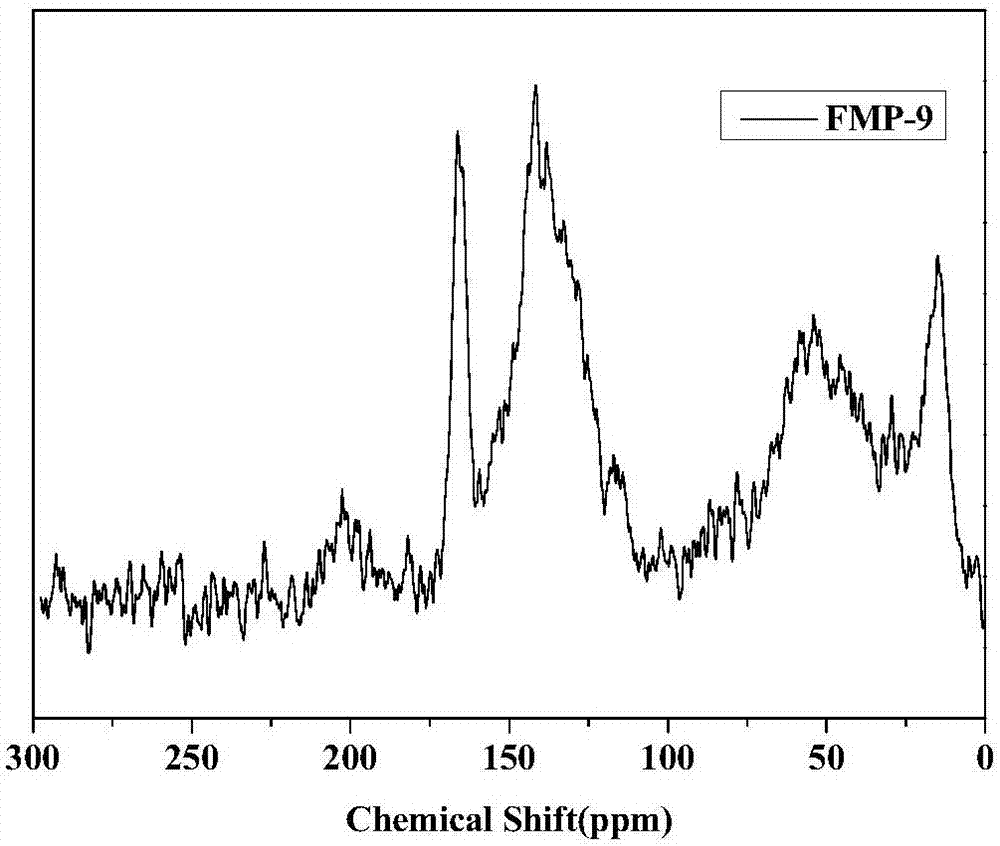

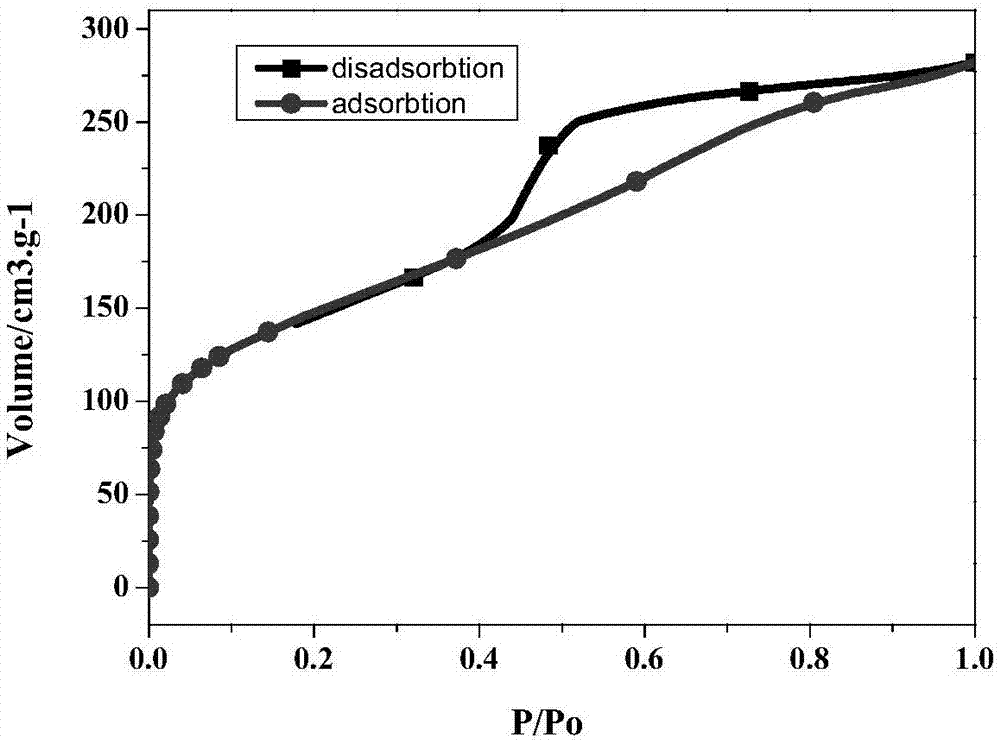

[0047] In a 50mL three-neck flask with magnetic stirring and reflux condenser, add melamine (0.2mol), diacetylferrocene (0.3mol) and DMSO in a molar ratio of 2:3 in sequence, and protect with nitrogen Under the condition of 150°C, the reaction was stirred and refluxed for 72 hours. The precipitate obtained after cooling the reaction liquid was collected by filtration and washed with water, then extracted by THF, acetone and methanol, and dried to obtain the product. After the sample is subjected to vacuum conditions (10kPa), the ferrocene-based poly-Schiff base porous polymer pore material FMAP-9 is obtained. Measure TGA and BET respectively, the specific surface area is 924m 2 / g, the average pore size is 3.27nm, the 5% thermal weight loss temperature under nitrogen is 465°C, the hydrogen loading is 1.9wt% (77K, 1bar), the methane loading is 6.0wt% (298K, 25bar), and the carbon dioxide adsorption capacity 15.0wt%, CO 2 / N 2 The selectivity is 78 (298K, 1 bar).

Embodiment 2

[0049] Under similar conditions as in Example 1, dipropionyl ferrocene (0.3mol) was selected to replace diacetyl ferrocene as a polymerization monomer, and the BET specific surface area of the obtained ferrocene-based poly-Schiff base porous polymer porous material was 1162m 2 / g, the average pore size is 2.72nm, the 5% thermal weight loss temperature under nitrogen is 414°C, the hydrogen loading is 2.3wt% (77K, 1bar), the methane loading is 6.2wt% (298K, 25bar), and the carbon dioxide adsorption capacity 16.7wt%, CO 2 / N 2 The selectivity is 65 (298K, 1 bar).

Embodiment 3

[0051] Under similar conditions in Example 1, under similar conditions, select dibutyryl ferrocene (0.3mol) to replace diacetyl ferrocene as a polymerization monomer, and the BET ratio of the obtained ferrocene-based poly-Schiff base porous polymer pore material is Surface area is 1243m 2 / g, the average pore size is 2.13nm, the 5% thermal weight loss temperature under nitrogen is 407°C, the hydrogen loading is 2.3wt% (77K, 1bar), the methane loading is 6.7wt% (298K, 25bar), and the carbon dioxide adsorption capacity 18.2wt%, CO 2 / N 2 The selectivity is 92 (298K, 1 bar).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com