A kind of nitration method of aromatic compound

A technology for aromatic compounds and mixtures, which is applied in the field of nitration of aromatic compounds, can solve the problems of uneven mixing of tank reactors, flammable and explosive organic substances, complicated processes, etc., so as to improve production efficiency and product quality, and avoid side effects. The effect of less reaction and material accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

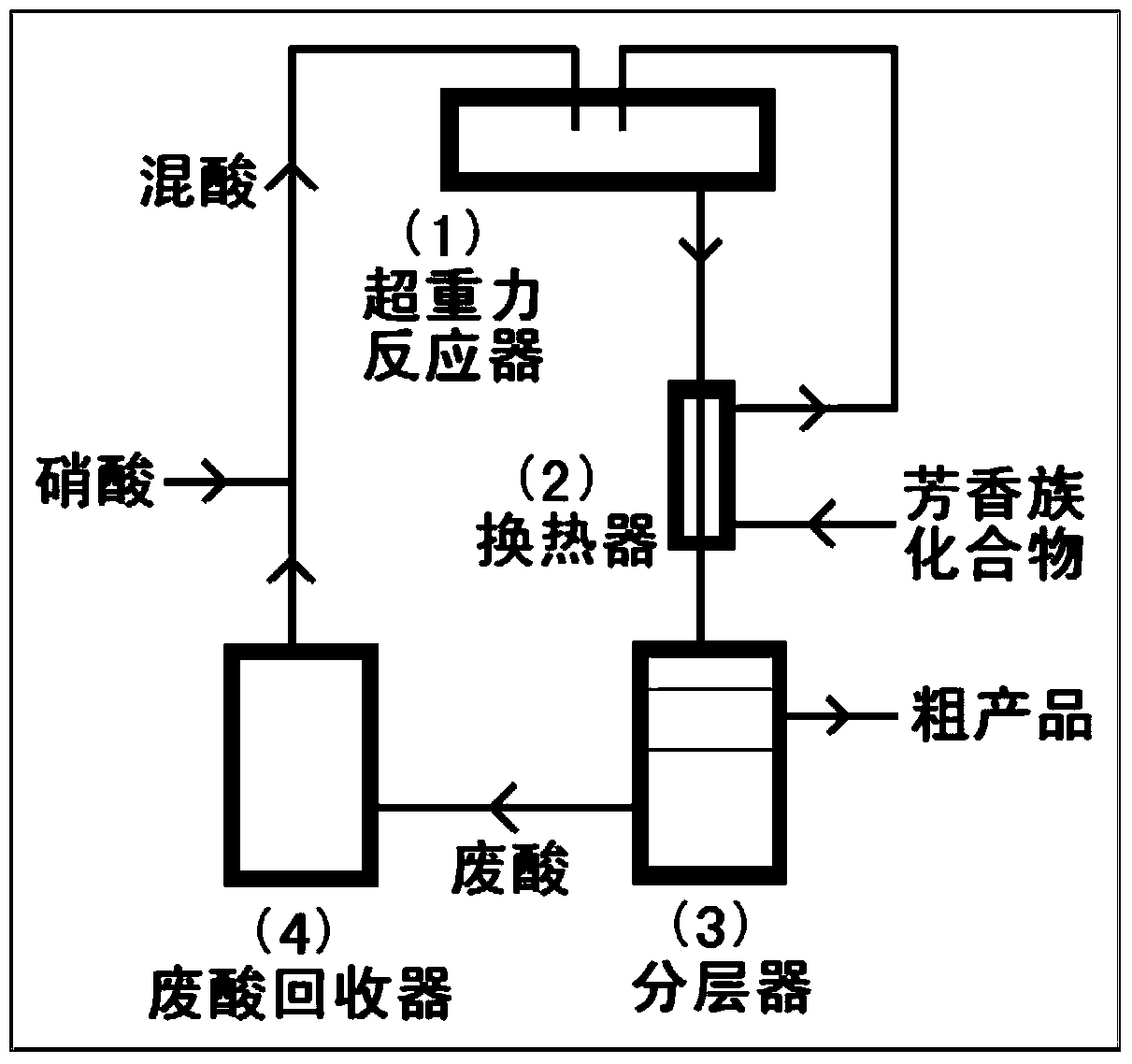

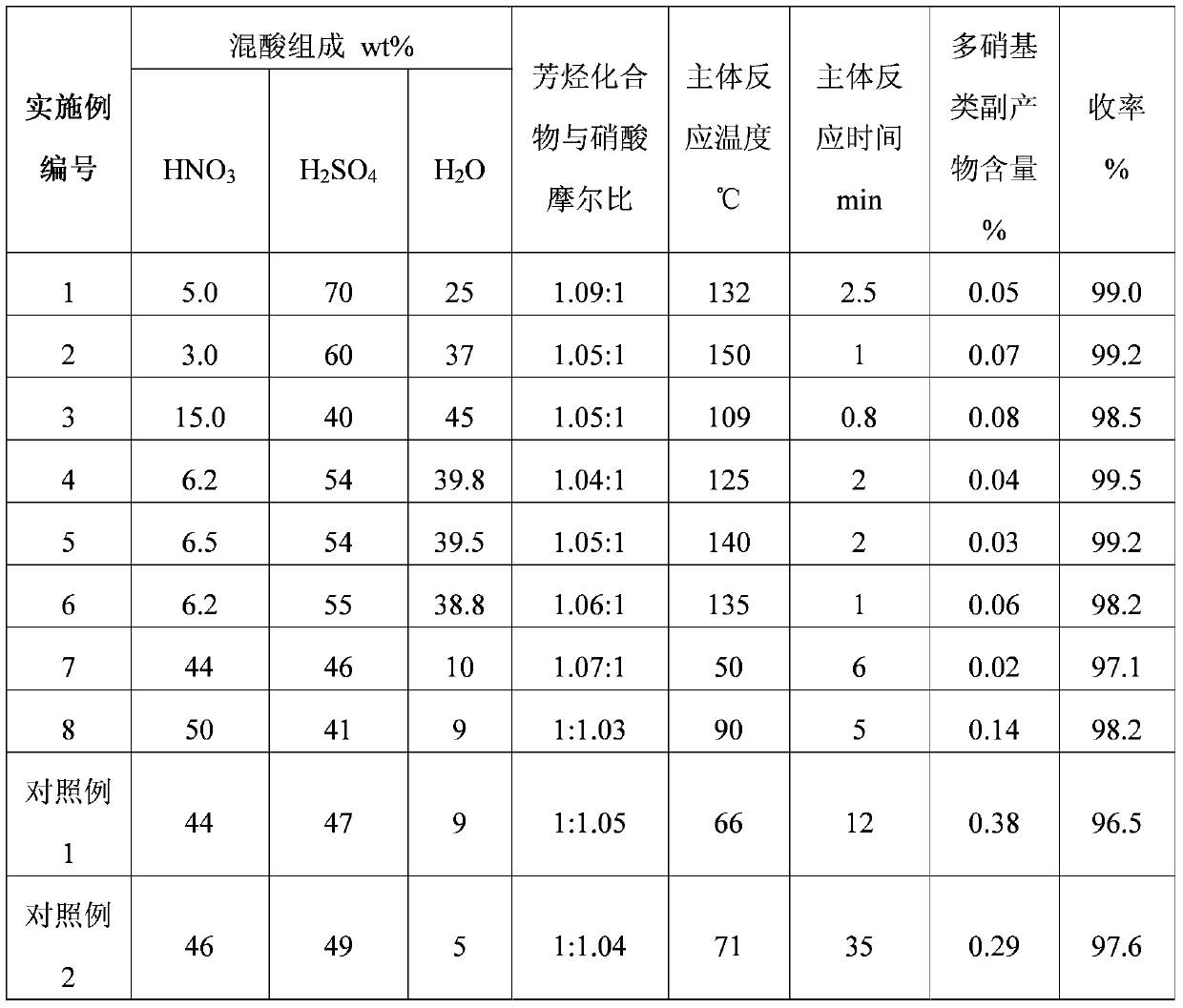

[0031] Example 1 uses a high-gravity rotating packed bed as the core reactor device, and sets the high-gravity level to 2g-5g. Take a certain amount of sulfuric acid, nitric acid, and water to form a mixed acid, and input the benzene and mixed acid into the supergravity reactor 1 at the same time. The materials are efficiently mixed in the supergravity reactor and nitrated. After heat exchange, it enters the stratifier 3. After stratification, the crude product in the upper layer is treated as the final product through subsequent purification, and the waste acid obtained by stratification enters the waste acid recovery device 4. After concentration, the waste acid is mixed with nitric acid to obtain mixed acid. , to be recycled again, and will be input into the high-gravity reactor 1 simultaneously with benzene. Relevant conditions of the reaction are shown in Table 1. After analysis and detection, the yield was 99%.

Embodiment 2

[0032] Example 2 uses a supergravity rotating packed bed as the core reactor device, and sets the supergravity level to 800g. Take a certain amount of sulfuric acid, nitric acid, and water to form a mixed acid, and input the toluene and the mixed acid into the supergravity reactor 1 at the same time. The materials are efficiently mixed in the supergravity reactor and nitrated. After heat exchange, it enters the stratifier 3. After stratification, the crude product in the upper layer is treated as the final product through subsequent purification, and the waste acid obtained by stratification enters the waste acid recovery device 4. After concentration, the waste acid is mixed with nitric acid to obtain mixed acid. , recycle, and will be input in the high-gravity reactor 1 simultaneously with toluene. Relevant conditions of the reaction are shown in Table 1. After analysis and detection, the yield was 99.2%.

Embodiment 3

[0033] Embodiment 3 uses a baffle type supergravity device as the core reactor device, and sets the supergravity level to 150g. A certain amount of sulfuric acid, nitric acid, and water are mixed to form a mixed acid, and the chlorobenzene and the mixed acid are simultaneously input into the supergravity reactor 1. The materials are efficiently mixed in the hypergravity reactor and nitration reaction occurs, and the reacted materials enter the heat exchanger 2. After heat exchange, it enters the stratifier 3. After stratification, the crude product in the upper layer is treated as a final product through subsequent purification. The waste acid obtained by stratification enters the waste acid recovery device 4, and the waste acid is concentrated and mixed with nitric acid to obtain Mixed acid, recycled, will be input in the high gravity reactor 1 simultaneously with chlorobenzene. Relevant conditions of the reaction are shown in Table 1. After analysis and detection, the yield ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com