Manganese molybdate micro-nano bundle and method for preparing same

A manganese molybdate micro-nano, micro-nano technology, applied in chemical instruments and methods, manganese compounds, inorganic chemistry, etc., can solve the problems of complex process, adding a large amount of surfactants, etc., to achieve large specific surface area and improve electrochemical performance. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

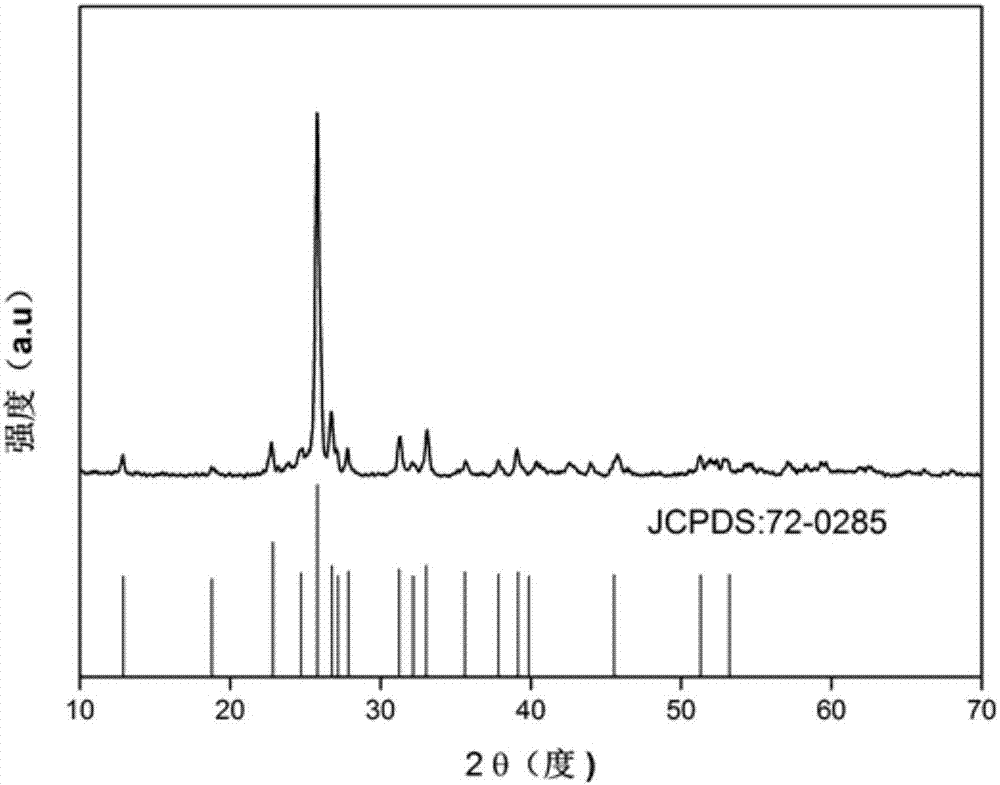

Image

Examples

preparation example Construction

[0021] A kind of preparation method of manganese molybdate micronano bundle provided by the invention comprises the following steps:

[0022] The first step is to configure an aqueous solution of manganese acetate tetrahydrate with a concentration of 0.1 to 3 mol / L;

[0023] The second step is to configure 0.05-0.2mol / L sodium molybdate dihydrate solution;

[0024] The third step is to mix the manganese acetate tetrahydrate aqueous solution and the sodium molybdate dihydrate solution according to the volume ratio of 1:1~2, after stirring evenly, pour it into the reaction kettle and seal it. Under the temperature of hydrothermal reaction for 3 to 5 hours, after the reaction is complete, it is suction filtered, washed and dried to obtain the intermediate product;

[0025] The fourth step is to put the intermediate product obtained above into a tube furnace, and under an argon atmosphere, the calcination temperature is 400°C-600°C, and the heating rate is 3°C·min -1 , after cal...

Embodiment 1

[0030] The first step, configuration concentration is the manganese acetate tetrahydrate aqueous solution of 0.1mol / L;

[0031] Second step, configure the sodium molybdate dihydrate solution of 0.05mol / L;

[0032] The third step is to mix manganese acetate tetrahydrate aqueous solution and sodium molybdate dihydrate solution according to the volume ratio of 1:1, after stirring evenly, pour it into the reaction kettle and seal it, and at the same time, hydrothermally react at a temperature of 120°C 3h, then it was suction filtered, washed and dried to obtain an intermediate product;

[0033] The fourth step is to put the intermediate product obtained above into a tube furnace, and under an argon atmosphere, the calcination temperature is 400°C, and the heating rate is 3°C·min -1 , calcined for 3 hours, and cooled to room temperature to obtain manganese molybdate micronano bundles.

Embodiment 2

[0035] The first step, configuration concentration is the manganese acetate tetrahydrate aqueous solution of 1mol / L;

[0036] Second step, configure the sodium molybdate dihydrate solution of 0.1mol / L;

[0037] The third step is to mix the manganese acetate tetrahydrate aqueous solution and the sodium molybdate dihydrate solution according to the volume ratio of 1:1.4. After stirring evenly, pour it into the reaction kettle and seal it. 4h, then it was suction filtered, washed and dried to obtain an intermediate product;

[0038] The fourth step is to put the intermediate product obtained above into a tube furnace, and under an argon atmosphere, the calcination temperature is 500°C, and the heating rate is 3°C·min -1 , calcined for 4h, and cooled to room temperature to obtain manganese molybdate micronano bundles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com