Shock-resistant composite shell and preparation method thereof

A composite material and impact-resistant technology, applied in the field of impact-resistant composite material shell and its preparation, can solve the problems of difficult processing and insufficient anti-drop damage ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

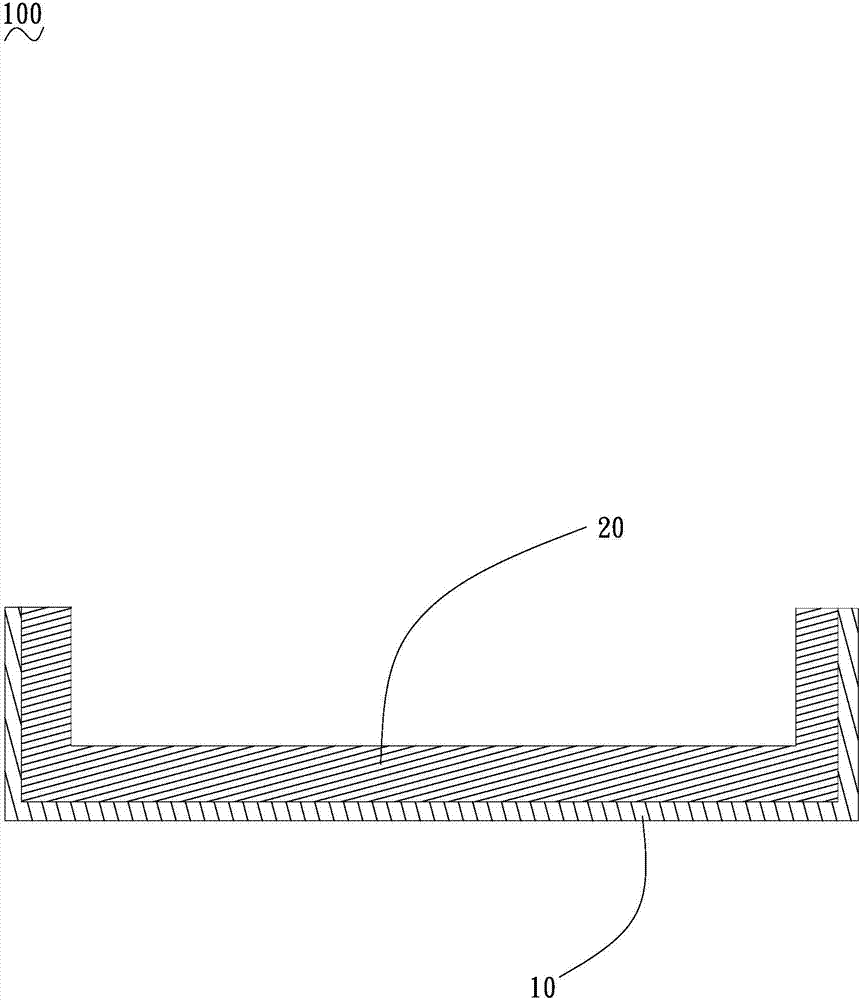

[0038] A method for preparing an impact-resistant composite shell 100, the impact-resistant composite shell 100 includes a surface layer 10 and a toughening layer 20 arranged sequentially from outside to inside; the surface layer 10 is a ceramic layer; the toughened The layer 20 is composed of fiber reinforced material and matrix material; the impact-resistant composite shell 100 is prepared according to the following steps: a. The ceramic powder is prepared into a surface ceramic layer with a thickness of 0.01-0.5 mm by molding, degreasing, sintering and other processes ; b, put the prepared surface ceramic layer into the lower mold, evenly lay a layer of fiber reinforced material on the surface ceramic layer; c, cover the upper mold, and put the molten matrix material along the gap between the upper mold and the lower mold The cracks are poured to form a toughening layer 20 with a thickness of 0.5-2 mm; finally, natural cooling is performed to obtain an impact-resistant compo...

Embodiment 1

[0045] The present invention provides a method for preparing an impact-resistant composite shell 100, wherein the impact-resistant composite shell 100 includes a surface layer 10 and a toughening layer 20 arranged in sequence from outside to inside; the surface layer 10 is a ceramic layer The toughened layer 20 is made of fiber reinforced material and matrix material; the impact-resistant composite shell 100 is prepared according to the following steps: a. The ceramic powder is prepared by molding, degreasing, sintering and other preparation processes to a thickness of 0.01- 0.5mm surface ceramic layer; b. Put the prepared surface ceramic layer into the lower mold, and evenly lay a layer of fiber reinforced material on the surface ceramic layer; c. Cover the upper mold, and put the molten matrix material along the upper mold. The gap between the mold and the lower mold is poured to form a toughening layer 20 with a thickness of 0.5-2mm; finally, it is naturally cooled to obtain...

Embodiment 2

[0047] The present invention provides a method for preparing an impact-resistant composite shell 100, wherein the impact-resistant composite shell 100 includes a surface layer 10 and a toughening layer 20 arranged in sequence from outside to inside; the surface layer 10 is a glass layer ; The toughening layer 20 is composed of a fiber reinforced material and a matrix material; the impact-resistant composite shell 100 is prepared according to the following steps: a. The glass powder is prepared into a thickness of 0.01 through melting, molding, surface strengthening and other preparation processes; ~0.5mm surface glass layer; b. Put the prepared surface glass layer into the lower mold, and evenly lay a layer of fiber reinforced material on the surface glass layer; c. Cover the upper mold, and put the molten matrix material along the The gap between the upper mold and the lower mold is poured to form a toughening layer 20 with a thickness of 0.5-2 mm; finally, it is naturally coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com