Method for enhancing slurry cutting capability

A slurry and capacity technology, applied in stone processing equipment, fine working devices, manufacturing tools, etc., can solve problems affecting production efficiency, ingot scrapping, deep line marks on the surface of ingots, etc., to improve the high-quality rate of prescribing and square extraction efficiency, ensuring the ability to carry sand, and saving the cost of square extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

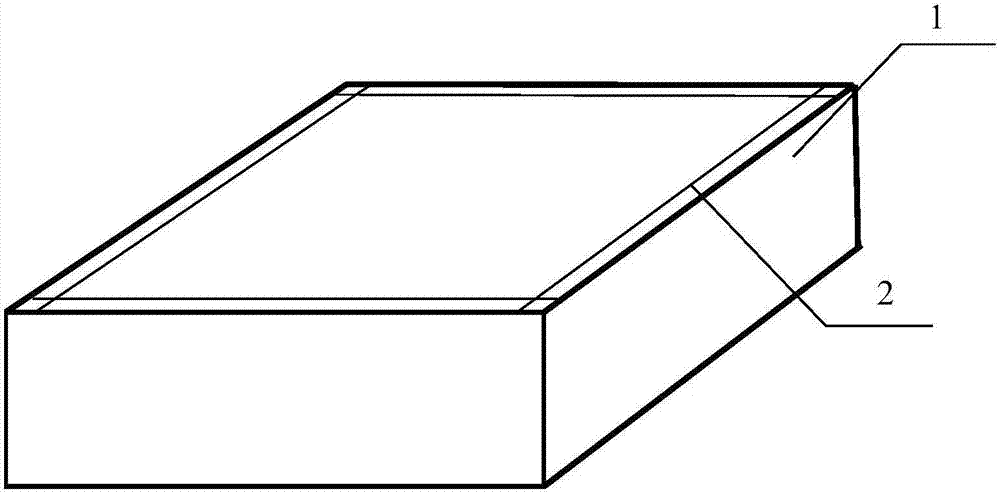

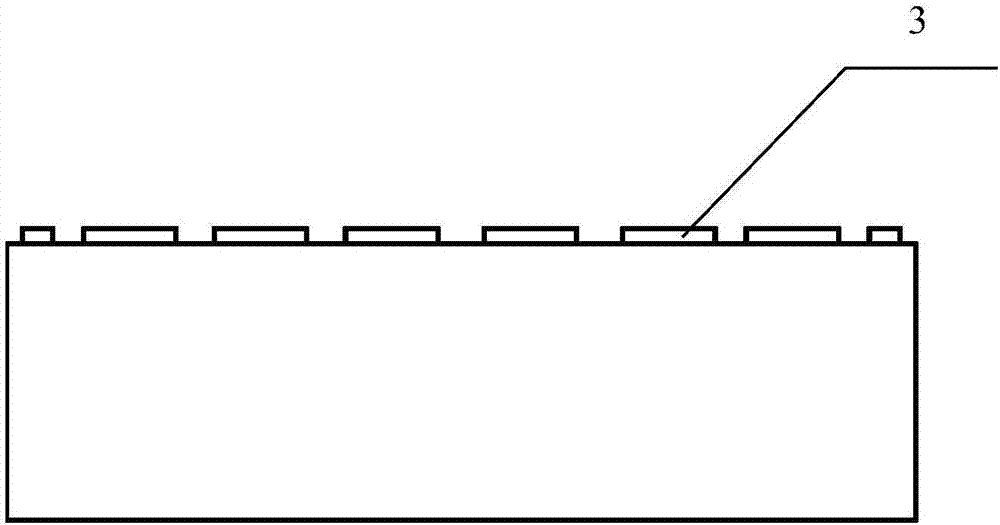

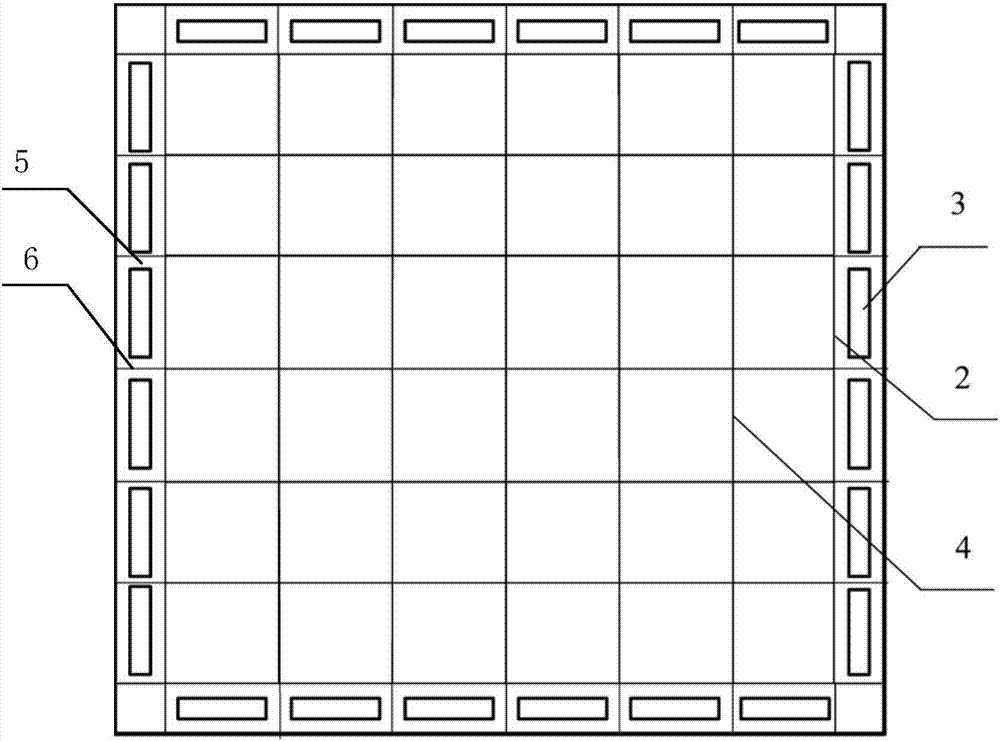

[0026] Such as Figure 1 to Figure 4 As shown, a method for enhancing the cutting ability of slurry provided by the present invention includes the following steps in turn: Step 1: before square opening, draw four edge reference lines 2 along the positions of the four edge edges on the upper surface of the ingot 1, and the edge edge The reference line 2 is the line drawn at the position of the ingot 1 close to the edge of the ingot before the square of the ingot is used to determine the cutting position of the ingot 1; Step 2: set up multiple interceptions along the length direction of the edge reference line 2 on its outer side Part 3 is used to block the slurry to prevent its loss and drain the slurry to the cutting wire mesh 4;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com