Belt sander workbench convenient for loading and unloading

A belt machine and workbench technology, which is applied to belt grinders, manufacturing tools, grinding racks, etc., can solve problems such as high labor intensity, achieve the effects of reducing labor intensity, ensuring effective transmission, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

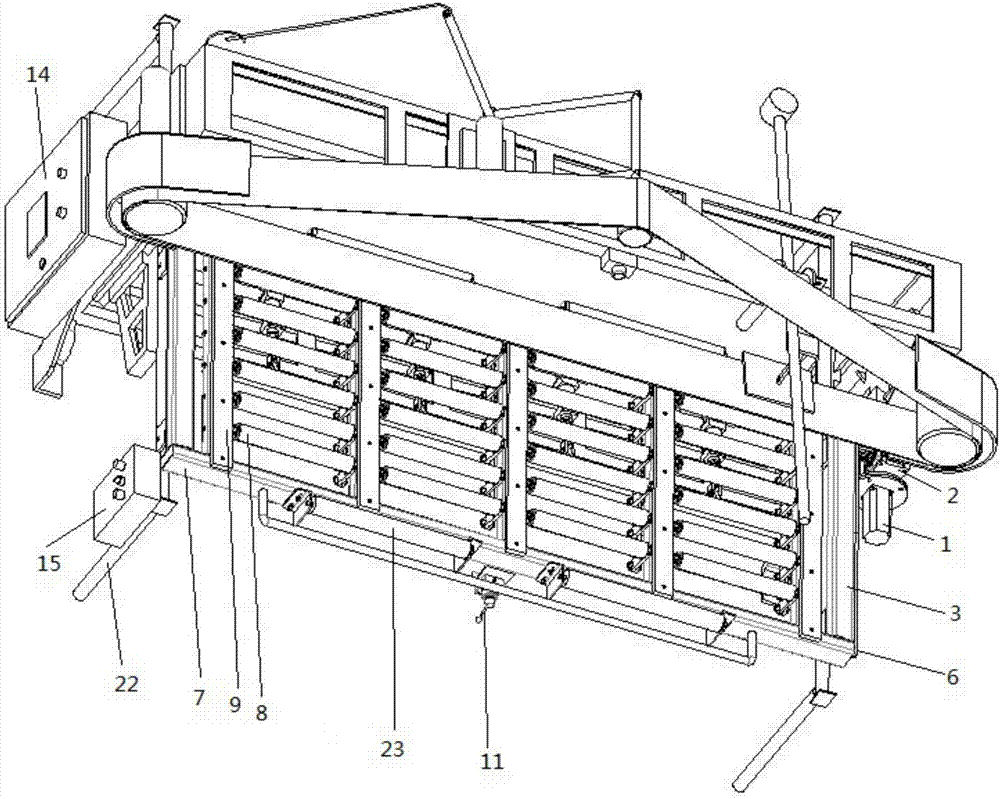

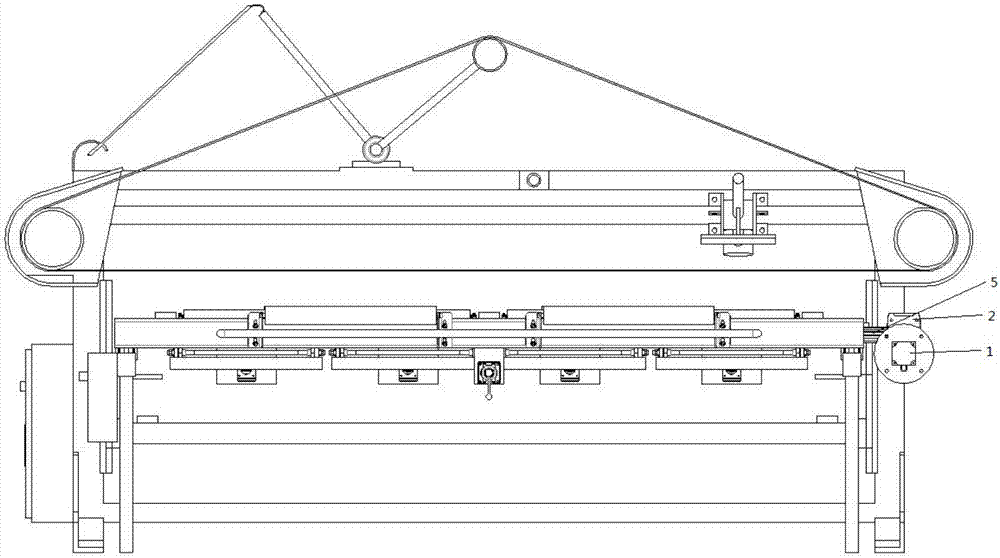

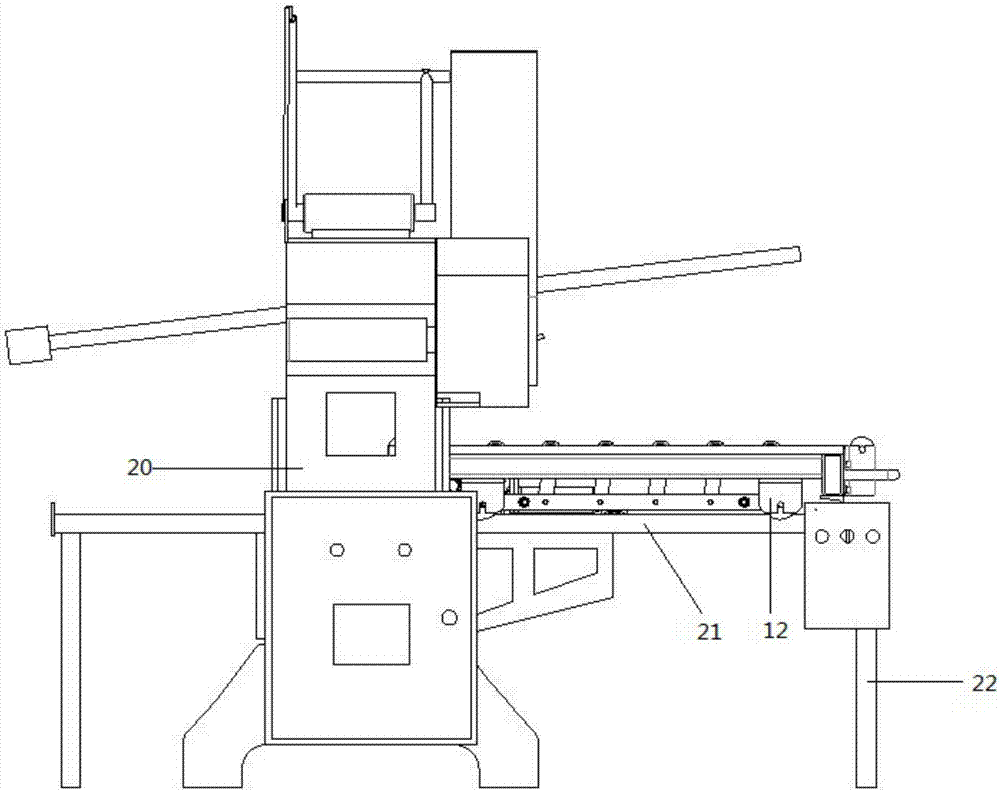

[0027] Such as Figure 1-4 As shown, an automatic walking abrasive belt machine for loading and unloading materials includes an abrasive belt, a motor, a pulley and a transmission device connecting the motor and the pulley. The motor drives the pulley through the transmission device, and the pulley drives the abrasive belt to operate. It also includes Frame 20, the workbench that is arranged on the abrasive belt below, workbench comprises the workbench 3 and reciprocating operation device that are convenient to loading and unloading.

[0028] The worktable 3 comprises a rough-surfaced table frame 7, a driving device 4 and a transmission device. Several lifting rollers 8 are installed in the table frame 7, and the driving device 4 drives the lifting roller 8 to lift through the transmission device.

[0029] The reciprocating operation device includes a servo motor 1, a travel transmission device, a pulley device and a control device for supporting the reciprocating travel of th...

Embodiment 2

[0033] Such as figure 1 As shown, further optimized on the basis of the workbench described in Embodiment 1, the loading and unloading edges of the table frame 7 are uniformly provided with some unloading rollers 23, and the unloading rollers 23 are higher than the table frame 7.

[0034] In this embodiment, the unloading roller can effectively reduce the wear of the non-processing surface of the workpiece and the worktable during the loading and unloading process; when multiple abrasive belt machines are used online, the rolling connection between the abrasive belt machines is increased to facilitate The workpiece is pushed online; it has a further limit function when processing the workpiece.

Embodiment 3

[0036] Such as figure 1 As shown, it is further optimized on the basis of the workbench described in Embodiment 1. The table frame 7 is a frame structure, and the frame is divided into several parts by a plurality of partition plates 10. The two sides of the table frame 7 and A wear-resistant Bakelite 9 is arranged above the dividing plate 10 .

[0037] In this embodiment, the frame structure of the table top frame 7 is convenient for the installation of the lifting roller, and the wear-resistant bakelite 9 ensures the roughness of the table top frame surface and is durable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com