A segmented contact type hot rolling roll shape detection device

A detection device, technology of hot rolls, applied in the direction of length measuring device, workpiece cooling device, metal rolling, etc., can solve the problem of low measurement accuracy, achieve high measurement accuracy, reasonable and simple device, and good dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated below in conjunction with accompanying drawing:

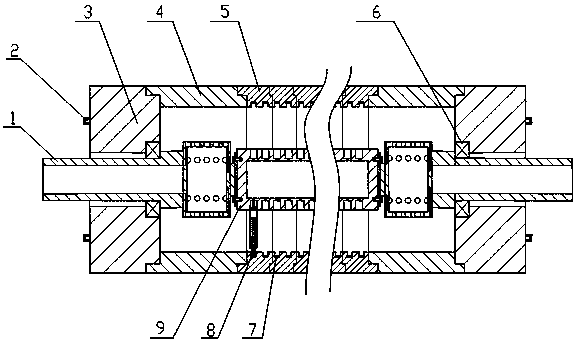

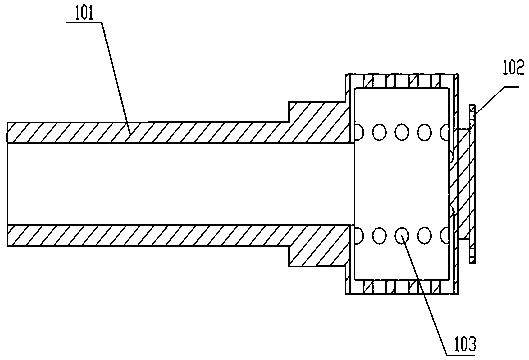

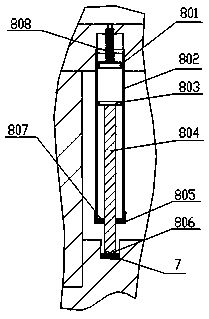

[0027] Such as figure 1 , figure 2 As shown, a segmented contact type hot roll shape detection device mainly includes a main roll body, a water inlet and outlet device 1 , a detection device 8 and a data processing control center 10 . The main roller body includes an outer roller and an inner roller, wherein the outer roller is segmented and consists of two outer roller end covers 3, two outer roller pads 4 and a plurality of segmented outer rollers 5, and the inner roller 9 is Integral type, the outer roller is rotated by the static friction of the plate, and the inner roller is fixed.

[0028] The outer roll cover 3 and the outer roll pad 4, the outer roll pad 4 and the segmented outer roll 5, one end of the segmented outer roll 5 and the other end of the other segmented outer roll 5 are all connected by interference fit, and After the assembly is completed, flat wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com