Net belt flat return screen and corresponding grain impurity removing method

A mesh belt and grain technology, applied in chemical instruments and methods, sieves, solid separation, etc., can solve the problems of inconvenient operation, large floor space, and inability to remove large impurities, so as to increase penetration rate and improve processing. Ability, the effect of increasing the amount of exercise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

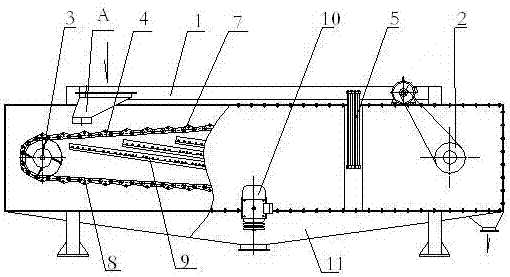

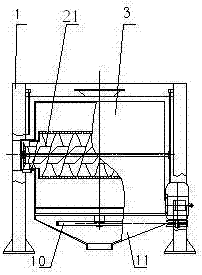

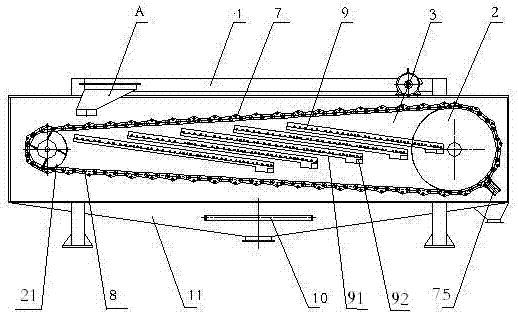

[0060] Mesh belt flat return screen, its composition includes: a screen frame 1 with a grain inlet A, the motor is connected to the sprocket 2 through a transmission mechanism, the shaft of the sprocket is hinged on the screen box 3, and two pairs of the chain The wheels are respectively connected by chains 4, and the screen box 3 is hoisted by the boom 5 or the rocker 5 in the screen frame, so that the material can realize the reciprocating linear motion in the screen frame and make a circular shape through the flat return mechanism. Flat back movement, compounding the movement form of grain spiral forward, a group of metal sieves 6 are arranged in sequence to form a conveyor belt, and driven by the chain 4, the conveyor belt can carry out grain transportation, diffusion, and grain screening, and The metal sieves 6 can rotate with each other, so that the entire conveyor belt can be bent, and an inclined conveyor plate 9 is installed in the space between the upper sieve surface...

Embodiment 2

[0062] In the mesh belt flat return screen described in Example 1, the metal sieve 6 is a punched sieve, and dense sieve holes are arranged on the metal sieve, which can be punched by punching. The metal sieve The sieve hole side length of sheet 6 is 10-30mm, or the diameter is 8-14mm. One side of the metal sieve sheet has a reinforcing edge 61 and an avoiding edge 62; it is effective to avoid when turning and avoid interference. The screen box has a set of idler rollers 63 for the metal sieve plates, respectively supporting the metal screen sheets of the upper layer and the metal screen sheets of the lower layer; or the screen box has a set of chain brackets or supporting wheels 64, which Side lift chain. Described chain 4 also has the transition board 41 that is connected with described metal sieve sheet 6. The bottom of described metal sieve sheet is equipped with vibrator, removes the grain that is plugged in the sieve hole by vibration.

Embodiment 3

[0064] In the mesh belt flat return screen described in embodiment 1 or 2, the metal sieve 6 is a metal mesh with a support frame 65 for rigidity reinforcement, and the side length of the mesh in the metal sieve is 8-24mm. The width is 6-12mm, and the length and width are greater than the long side of the grain to be screened. The metal sieve is connected in sequence by a group of mesh framed metal sieves, or a metal mesh belt formed by an annular mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com