Shield structure for internal combustion engine

An internal combustion engine and shield technology, which is applied to the sealing device of the engine, mechanical equipment, engine components, etc., can solve the problems of increased weight, reduced compression ratio, and large size of the holding member 313, and achieves the goal of promoting light weight and improving sealing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

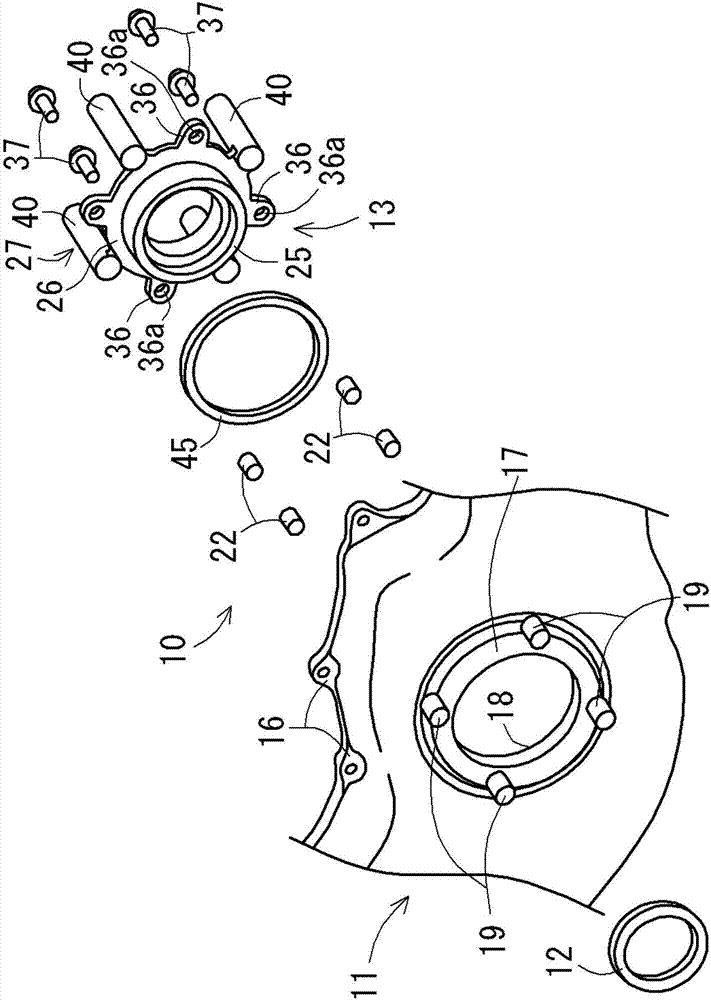

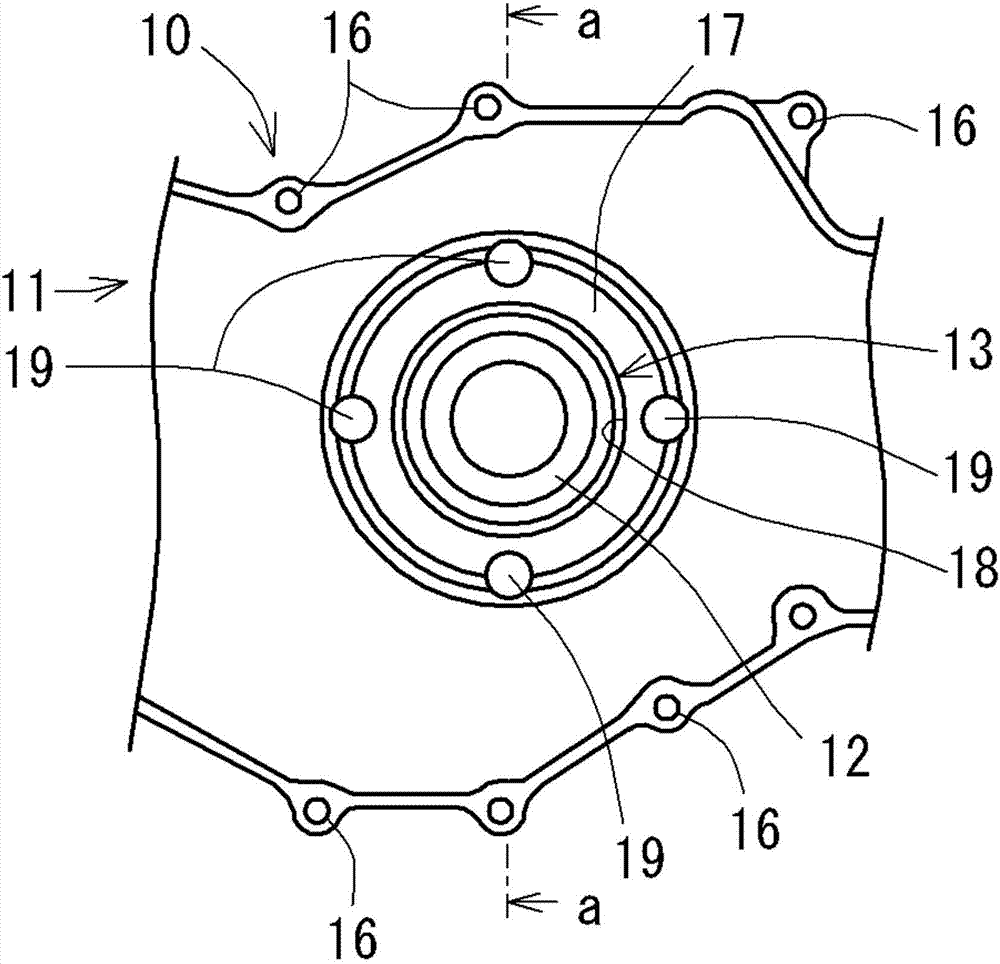

[0066] (1) Engine guard structure

[0067] Such as figure 1 with figure 2 As shown, the engine shroud structure 10 of this embodiment is used to cover and protect the power transmission part 5 that transmits power from the crankshaft 3 to the camshaft of the engine. The shroud structure 10 includes: a shroud member 11 made of resin (for example, made of polyamide resin) capable of being attached to the engine main body 2 so as to cover the power transmission portion 5 ; and a holding member 13 , It is made of metal (such as aluminum alloy), and this holding member 13 holds the oil seal 12 that is crimped to the outer peripheral surface of the crankshaft 3 .

[0068] The shroud member 11 is formed in a box shape with one side open so as to be able to cover one side surface of the engine main body 2 . A plurality of fastening portions 16 that can be fastened to the engine main body 2 by fastening bolts 15 are provided on the opening end side of the shroud member 11 . And, ...

Embodiment 2

[0088]Next, the engine shroud structure of the second embodiment will be described. In addition, in the engine shroud structure of the second embodiment, the same reference numerals are attached to the structural parts substantially the same as those of the engine shroud structure 10 of the first embodiment described above, and detailed descriptions are omitted. Portions having substantially the same functions as those of the engine shroud structure 10 will be described with "A" appended to the same reference numerals.

[0089] (1) Engine guard structure

[0090] Such as Figure 11 As shown, the engine guard structure 10A of this embodiment has a guard member 11A made of resin (for example, made of polyamide resin, etc.), and the guard member 11A can be attached to the engine so as to cover the power transmission part 5 . Main body 2 ; and holding member 13A made of metal (for example, made of aluminum alloy) for holding oil seal 12 crimped on the outer peripheral surface of...

Embodiment 3

[0101] Next, the engine shroud structure of the third embodiment will be described. In addition, in the engine shroud structure of the third embodiment, the same reference numerals are attached to the structural parts substantially the same as those of the engine shroud structure 10 of the first embodiment described above, and detailed descriptions are omitted. Portions having substantially the same functions as those of the engine shroud structure 10 will be described with "B" attached to the same reference numerals.

[0102] (1) Engine guard structure

[0103] Such as Figure 14 As shown, the engine shroud structure 10B of this embodiment has: a shroud member 11B made of resin (for example, made of polyamide resin, etc.), and the shroud member 11B can be attached to the engine so as to cover the power transmission part 5 The main body 2 ; and a holding member 13B made of metal (for example, made of aluminum alloy) for holding the oil seal 12 crimped on the outer peripheral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com