High-grade adhesive for wallpaper and wall cloth

An adhesive and wallpaper technology, applied in the directions of polymer adhesive additives, adhesive types, non-polymer adhesive additives, etc. and other problems to achieve the effect of enhanced toughness, enhanced cross-linking, and improved water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

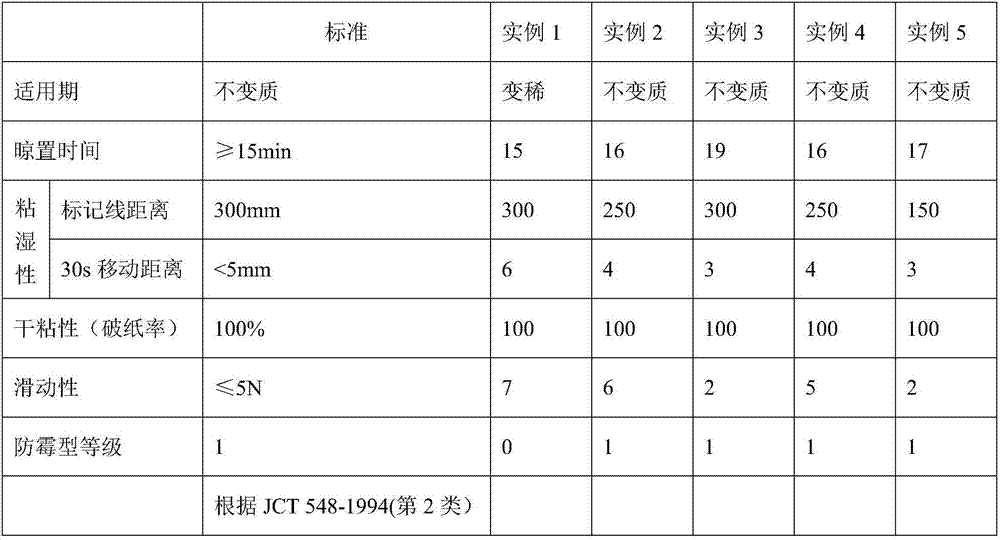

Examples

Embodiment 1

[0042] Select 45 parts by weight of styrene-acrylic emulsion, 20 parts by weight of 20 μm light calcium carbonate, 0.3 parts by weight of hydroxyethyl cellulose ether thickener, 0.1 parts by weight of polyoxypropylene glycerine ether defoamer, and 200 parts by weight of sodium polyacrylate dispersant , 0.1 parts by weight of dioctyl phthalate plasticizer, 0.5 parts by weight of potassium dihydrogen phosphate stabilizer, 0.5 parts by weight of bentonite thixotropic agent, 33.4 parts by weight of deionized water, mix the above components in proportion and put them into high-speed In the dispersing tank, stir well to make the required binder evenly.

Embodiment 2

[0044] Select 60 parts by weight of tertiary acrylic emulsion, 30 parts by weight of 45 μm heavy calcium carbonate, 0.3 parts by weight of hydroxyethyl cellulose ether thickener, 0.3 parts by weight of polyethylene glycol defoamer, and 0.3 parts by weight of sodium polyacrylate wetting and dispersing agent , 0.4 parts by weight of dioctyl phthalate plasticizer, 1.0 parts by weight of calcium hydrogen phosphate stabilizer, 2.0 parts by weight of magnesium aluminum silicate thixotropic agent, 0.5 parts by weight of sodium trichlorophenolate preservative, 5.2 parts by weight of deionized water Mix the above-mentioned components according to the proportion and put them into the high-speed dispersing kettle, stir well and evenly to make the required binder.

Embodiment 3

[0046] Select 45 parts by weight of styrene-acrylic emulsion, 30 parts by weight of 20 μm superfine calcium carbonate, 15 parts by weight of 40 μm superfine talcum powder, 0.3 parts by weight of dioctyl phthalate plasticizer, and 0.4 parts by weight of hydroxyethyl cellulose ether thickener Parts, 1.0 parts by weight of organic bentonite thixotropic agent, 0.3 parts by weight of polyethylene glycol defoamer, 0.3 parts by weight of sodium polyacrylate wetting and dispersing agent, 0.5 parts by weight of sodium acetate, 0.5 parts by weight of sodium trichlorophenolate, deionized water 6.7 parts by weight, mix the above-mentioned components according to the proportion and put them into the high-speed dispersion kettle, stir well and evenly to make the required binder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com