Self-cleaning superhard polysilazane hydrophobic coating and its preparation and use method

A polysilazane, hydrophobic coating technology, applied in the coating and other directions, can solve the problems of super-hydrophobic coating damage, poor hardness and scratch resistance of super-hydrophobic coating, etc., to overcome easy phase separation, not easy to fall off, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

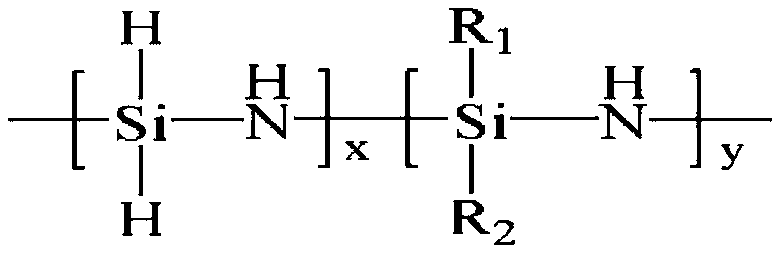

[0045] R in the organic-inorganic hybrid polysilazane of the present embodiment 1 =-CH 3 , R 2 =-HC=CH 2 , which is prepared as a superhydrophobic coating, the method is as follows:

[0046] (1) Mix 12 parts of the above-mentioned organic-inorganic hybrid polysilazanes, 23 parts of hydrophobic acrylate resins, 8 parts of nano-silicon dioxide, and 200 parts of xylene, and evenly coat the mixed solution on a glass slide, and then ℃, humidity 50%, 10 minutes to form a film, 2 hours after the surface is cured, 30 hours after complete curing, you can get a self-cleaning superhard coating.

[0047] (2) Use the GB / T 6739-2006 pencil method to measure the hardness of the paint film. After the coating is cured for 2 hours, its hardness is 8H. After 30 hours of complete curing, its hardness is 9H, and its contact angle is 150°. The rolling angle is 10°, and the coating has good superhydrophobic function. According to GB / T 9286-1998 standard, the adhesion level of the coating is 0, ...

Embodiment 2

[0049] R in the organic-inorganic hybrid polysilazane of the present embodiment 1 =-CH 3 , R 2 =-CF 3 , which is prepared as a superhydrophobic coating, the method is as follows:

[0050] (1) Mix 10 parts of above-mentioned organic-inorganic hybrid polysilazanes, 22 parts of hydrophobic acrylate resins, 7 parts of nano-silica, and 200 parts of xylene, and evenly coat the mixed solution on a glass slide, and in 10 parts ℃, humidity 45%, film formation in 9 minutes, surface curing after 1.8 hours, and complete curing after 26 hours, the self-cleaning superhard coating can be obtained.

[0051] (2) Use the GB / T 6739-2006 pencil method to measure the hardness of the paint film. After the coating is cured for 1.8 hours, the hardness is 8H. After 26 hours of complete curing, the hardness is 9H, and the contact angle is 150° , the rolling angle is 5°, and the coating has a good superhydrophobic function. According to GB / T 9286-1998 standard, the adhesion level of the coating is ...

Embodiment 3

[0053] R in the organic-inorganic hybrid polysilazane of the present embodiment 1 =-H, R 2 =-CH 3 , which is prepared as a superhydrophobic coating, the method is as follows:

[0054] (1) Mix 11 parts of the above-mentioned organic-inorganic hybrid polysilazanes, 24 parts of hydrophobic acrylate resins, 6 parts of nanometer silicon dioxide, and 200 parts of xylene, and coat the mixed solution evenly on a glass slide, and in 20 ℃, humidity 32%, film formation in 8 minutes, surface curing after 1.5 hours, and complete curing after 21 hours, the self-cleaning superhard coating can be obtained.

[0055] (2) Use the GB / T 6739-2006 pencil method to measure the hardness of the paint film. After the coating is cured for 1.5 hours, the hardness is 8H. After 21 hours of complete curing, the hardness is 9H, and the contact angle is 155° , the rolling angle is 8°, and the coating has a good super-hydrophobic function. According to GB / T 9286-1998 standard, the adhesion level of the coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com