Recoating type universal epoxy anticorrosive paint for achieving four-season constructions with single curing agent

A technology of curing agent and antirust paint, applied in the field of antirust paint, can solve the problems of short pot life, inapplicability, and limitation of the longest painting interval, etc., and achieve the effect of extending pot life

Inactive Publication Date: 2010-02-03

XIAMEN SUNRUI SHIP COATING

View PDF0 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Due to the strong reactivity of general low-temperature curing agents, when used at room temperature, the pot life of the coating after mixing is too short, causing workers to be unable to apply due to the short operating time; Too low activity and the coating dries too slowly to be applied

[0006] In terms of recoatability, although the shipyard hopes that the general-purpose epoxy antirust paint can be repainted and the restriction on the longest painting interval is lifted, but the products of individual manufacturers of general-purpose epoxy antirust paint on the market have achieved recoatability. The general-purpose epoxy coating products of most other manufacturers have a limit on the longest coating interval, which is usually 5-7 days at room temperature. If the longest coating interval is exceeded, the shipyard is often required to roughen the coating surface Increases adhesion between coats

There is no general-purpose epoxy anti-rust paint that can realize recoatability and a curing agent for four-season construction at the same time.

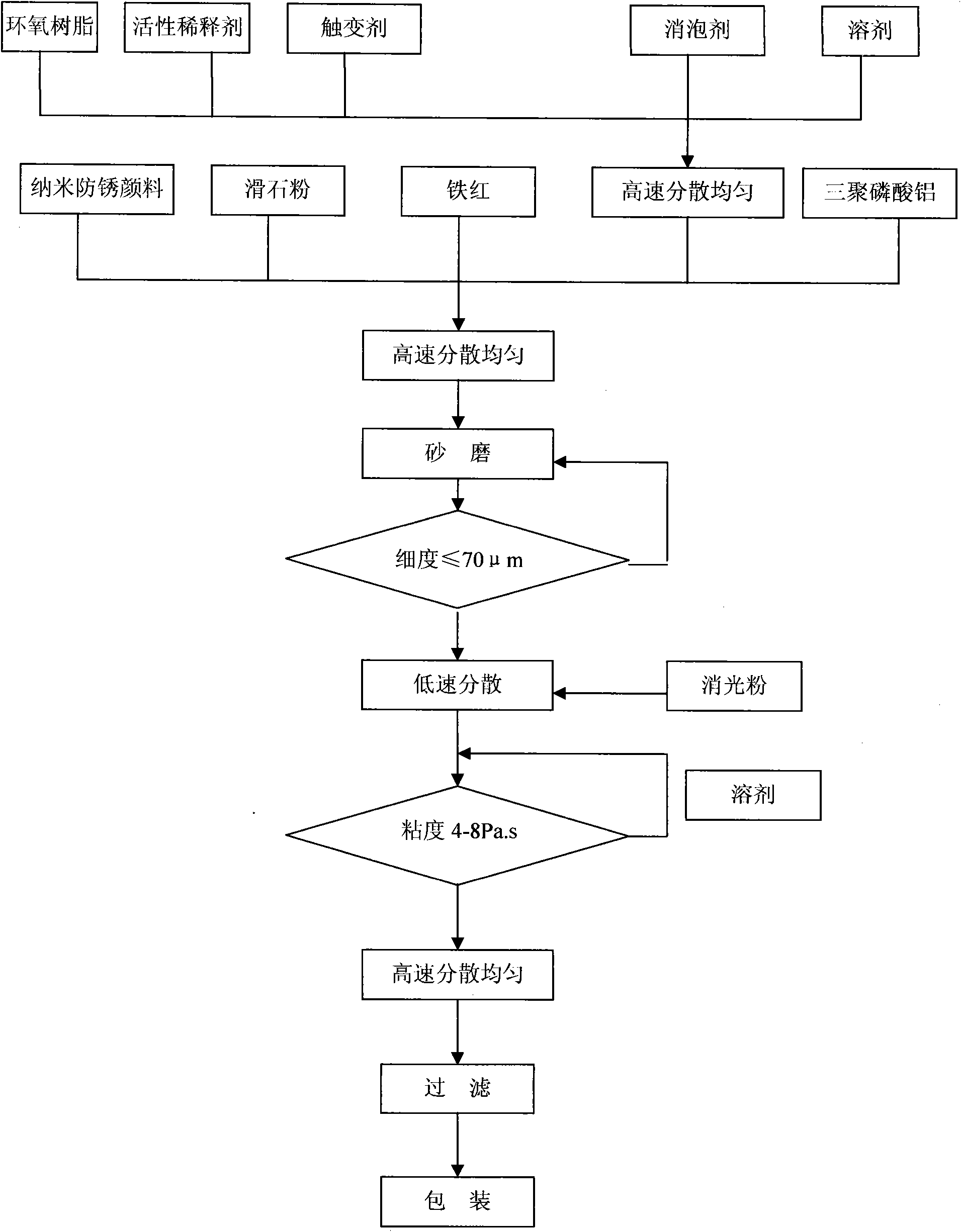

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0031] Embodiment of the present invention sees table 4:

[0032] Table 4 general epoxy antirust paint embodiment

[0033] Component A raw material name

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a recoating type universal epoxy anticorrosive paint for achieving four-season constructions with a single curing agent. A low molecular weight bisphenol A epoxy resin is usedas a resin base, a solvent system of an reactive diluent with branched chains, such as a glycidyl ether type reactive diluent, is introduced into the formulation to form an effective steric effect andprolong the usable life of a product after mixing, and after a coating layer is formed, the curing speed is not influenced, so the construction at the environment temperature of between 10 DEG C below zero and 40 DEG C is achieved, and the problem of the four-season constructions is solved by using one curing agent. A nano anticorrosive pigment, a phenolic amine curing agent, an adhesion promoter, adjusting PVC and a proper amount of dimming powder are selected, and the coating layer is ensured to contain a proper amount of polar groups so that the product has good cathodic disbonding resistance and can be matched with various types of finishing paints. The recoating type universal epoxy anticorrosive paint can be used as an anticorrosive primer for a plurality of positions from a ship bottom to a hull, and has very significant functions of improving the efficiency and the benefit of ship painting.

Description

technical field [0001] This patent relates to an antirust paint, in particular to a recoatable general-purpose epoxy antirust paint which can be applied in all seasons with a single curing agent. Background technique [0002] The general-purpose epoxy antirust paint can be applied to various parts of the ship from the bottom to the hull and the cabin, and can be matched with the cathode control and most of the bottom paints. Its application can greatly reduce the variety of coatings used, thereby simplifying the coating process, improving the logistics system of the shipyard, reducing inventory, increasing production speed, increasing the proficiency of on-site workers and reducing loss, so as to ensure timely delivery of ships and enhance shipyard competition. ability target. [0003] General-purpose epoxy antirust paint has been approved by shipyards as soon as it was launched in this century, and has been widely used. At present, only international large-scale multinati...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D163/02C09D5/08

Inventor 张东亚陈凯锋苏雅丽

Owner XIAMEN SUNRUI SHIP COATING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com