A kind of high conversion rate 107 silicone rubber production system and its production method

A technology with high conversion rate and production method, which is applied in the field of high conversion rate 107 silicone rubber production system, can solve the problems of unstable product quality, lower production cost, difficult process control, etc., to save dehydration consumption and related equipment investment, Promote the positive movement of the reaction balance and the effect of high comprehensive utilization of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

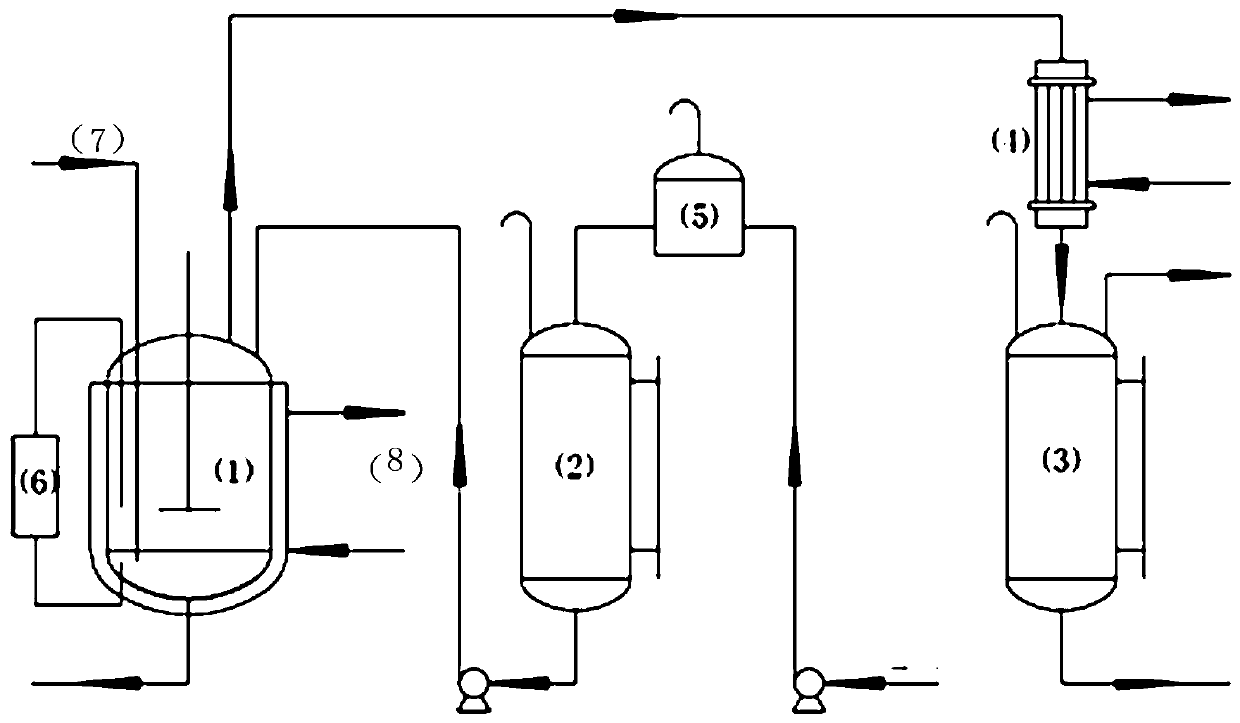

[0031] A high conversion rate 107 silicone rubber production system, comprising a polymerization kettle 1, the polymerization kettle 1 is connected with a feed metering tank 2 through a pipeline, and the feed metering tank 2 is connected with a filter 5 through a pipeline, and the filter 5 is equipped with a feed pipe; the filter 5 is a laminated precision filter or other precision filter, and the filtration accuracy is 0.2-10.0 μm;

[0032] The polymerization kettle 1 is also connected with the delowering condenser 4 through a pipeline, and the delowering condenser 4 is connected with the low molecular collector 3 through a pipeline.

[0033] Preferably, the polymerization kettle 1 is provided with a nitrogen inlet pipe 7, a discharge port, an online viscometer 6 and a heat transfer oil system 8;

[0034] Preferably, the top of the low molecular collector 3 is connected to a vacuum unit, the bottom of the low molecular collector 3 is connected to a low molecular tank; the del...

Embodiment 2

[0036] Adopt the system described in embodiment 1 to carry out the production method of high conversion rate 107 silicone rubbers, described method may further comprise the steps:

[0037] 1) Feed: the raw material enters the feed metering tank 2 after being removed by the filter 5, and then feeds into the polymerization kettle 1, and the feed amount is calculated according to the liquid level change of the feed metering tank 2;

[0038] 2) Polymerization: Turn on the stirring and heat transfer oil system of the polymerization kettle 1, add a basic catalyst after reaching the polymerization temperature, and pass dry nitrogen into the polymerization kettle 1 after a period of normal pressure reaction, and further polymerize after stopping the nitrogen;

[0039] 3) Neutralization: when the online viscometer 6 shows 5,000-200,000cp, add acid to neutralize and stop the reaction;

[0040] 4) Delowering: Polymerization kettle 1 internally removes the low molecular weight in the rubb...

Embodiment 3

[0048] Adopt the system described in embodiment 1 to carry out the production method of high conversion rate 107 silicone rubbers, described method is:

[0049]The raw material hydrolyzate with high linear siloxane content of 90% is removed by the filter 5 and enters the feed metering tank 2, and then feeds 1000kg from the metering tank to the polymerization kettle 1, and the heat transfer oil of the polymerization kettle 1 is turned on and stirred, and the temperature is raised After reaching 150°C, add 117g of 50% KOH aqueous solution, stir for 1h, and then pass dry nitrogen for 0.5h, and the nitrogen flow rate is 0.1m 3 / h, stop the nitrogen and continue to stir for 0.5h, add 117g of 85% phosphoric acid solution, neutralize for 1h and then raise the temperature to 160°C, start the vacuum unit to gradually increase the vacuum degree of the system to 0.1MPa, after 0.8h, no low molecules come out, low 102kg of low molecules were collected in the molecular collector 3, the conv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com