solid drug grinder

A grinder and drug technology, which is applied in the field of grinders, can solve the problems that drug particles are easy to collapse, affect the progress of experiments, and affect the grinding effect, so as to save medical costs, improve grinding speed and precision, and increase grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

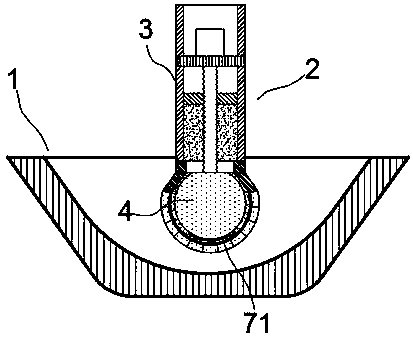

[0015] exist figure 1 , figure 2 In the shown embodiment, the solid medicine grinder includes a grinding disc 1 and a grinding rod 2, and the inner bottom of the grinding disc 1 is concaved to form an arc surface;

[0016] The grinding rod 2 includes a handle 3 and a grinding ball 4 installed at the handle 3; an elastic layer 5 is wrapped outside the grinding ball 4, and there is a gap between the elastic layer 5 and the grinding ball 4; the elastic Layer 5, grinding ball 4 and the end of the handle 3 are combined to form a closed spherical space 6, which is filled with regulating liquid; the handle 3 is provided with a regulating cylinder 31, and the regulating cylinder 31 passes through the guide hole and The spherical space 6 is connected; a piston plate 311 is arranged in the adjustment cylinder 31, and the piston plate 311 can reciprocate and slide airtightly on the cylinder wall of the adjustment cylinder 31; an adjustment ring 32 is also arranged on the handle 3, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com