Adjustable cloth drying and sizing device

A setting device and adjustable technology, applied in the field of textile printing and dyeing, can solve the problems of easy fading, uneven dyeing, etc., and achieve the effect of improving dyeing precision, reducing resource waste, and promoting dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The embodiments are described below with reference to the accompanying drawings. The embodiments shown below do not limit the invention content described in the claims. required for the solution.

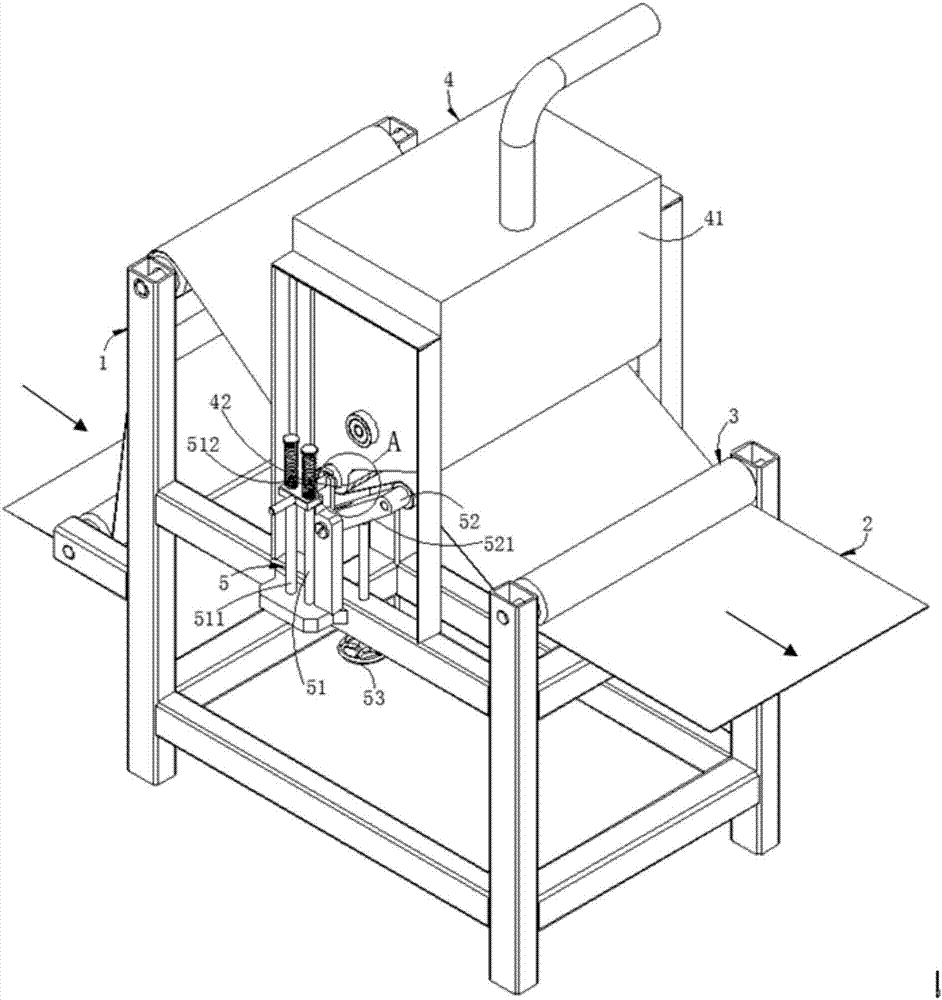

[0054] Such as figure 1 , 2 , Shown in 3 and 4, an adjustable cloth dyeing and setting device includes a frame 1, a cloth guide roller group 3 and a dyeing mechanism 4, and the dyeing mechanism 4 includes:

[0055] Dye bin 41, the dye bin 41 is fixedly installed on the frame 1;

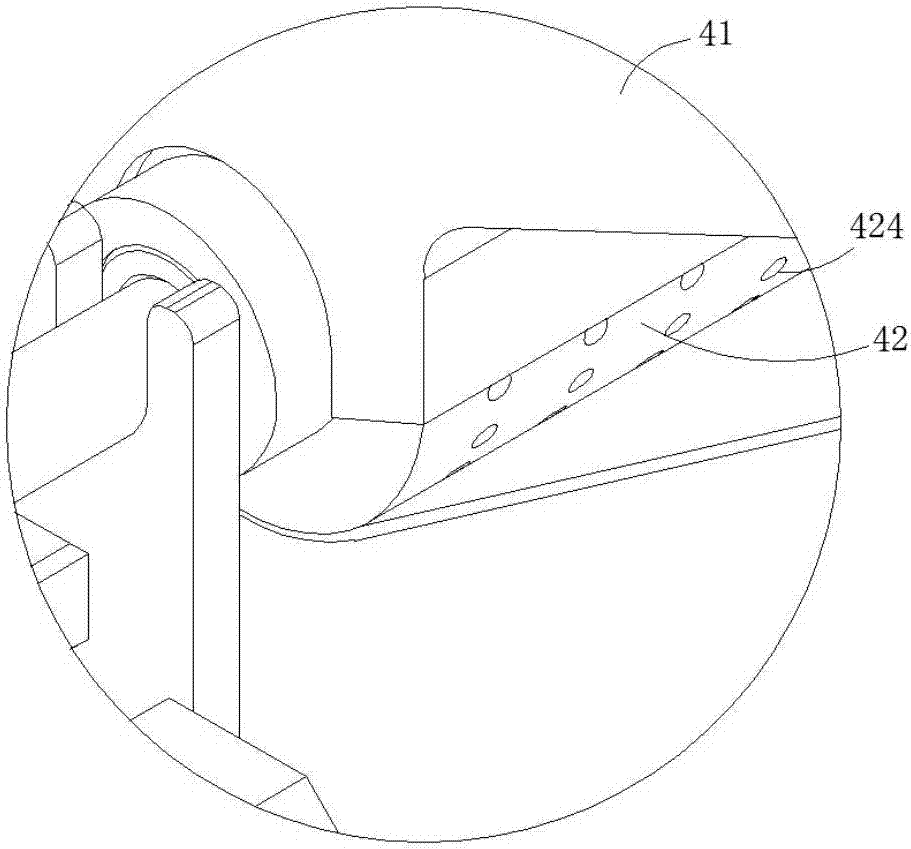

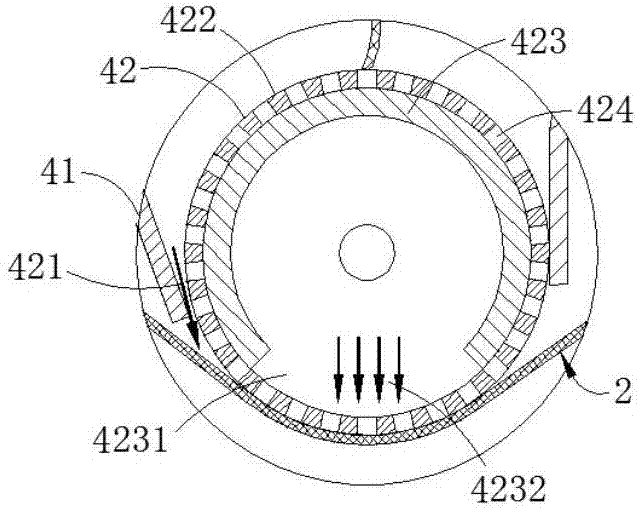

[0056]The dyeing roller assembly 42, the dyeing roller assembly 42 is installed inside the dye chamber 41, and forms a dye solution flow channel 421 with the dye chamber 41, including:

[0057] Rotating dyeing roller 422, the rotating dyeing roller 422 is installed on the frame 1 and the rotating dyeing roller 422 is rotated to apply and roll the dye solution on the gray cloth 2, the rotating dyeing roller 422 is hollow ;

[0058] A sealing baffle 423, the sealing baffle 423 is arranged inside t...

Embodiment 2

[0078] Components that are the same as or corresponding to those in the first embodiment use the reference numerals corresponding to those in the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between this embodiment two and embodiment one is: as figure 1 , 6 As shown, it also includes an adjustment mechanism 5 fixedly installed on the frame 1, and the adjustment mechanism 5 includes:

[0079] A positioning assembly 51, which is fixedly mounted on the frame 1 and arranged in cooperation with the dyeing roller assembly 42;

[0080] A tensioning assembly 52, which is rotatably mounted on the frame 1 and arranged in contact with the lower surface of the gray cloth 2;

[0081] Regulating valve 53, the regulating valve 53 is rotatably installed on the frame 1 and is set in contact with the tensioning assembly 52; when the tensioning assembly 52 adjusts and rotates the dyeing roller 422 to the expect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com