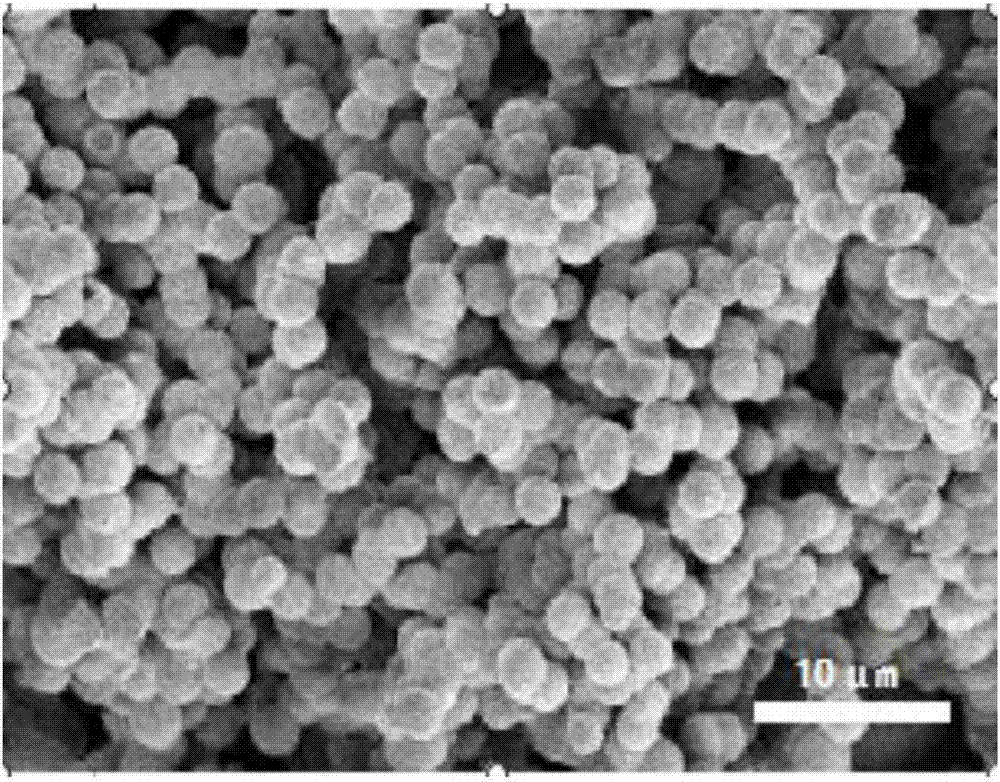

Preparation method and application of super-hydrophobic fluorine-containing block copolymer microspheres

A block copolymer, super-hydrophobic technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of increased polymer toxicity, difficulty in removal and conversion, complex preparation process, etc., to achieve fewer operation steps, reduce environmental problems and products. post-processing problems, molecular weight controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing superhydrophobic fluorine-containing block copolymer microspheres, comprising:

[0032] The 1L reactor was evacuated to remove moisture and air, followed by carbon dioxide and then evacuated three times; 0.7g perfluoroiodohexane (C 6 f 13 1) chain transfer agent is added in the reactor, and then adding 15g mass percent is 9:1 vinylidene fluoride and perfluoro-n-propyl vinyl ether, then 0.07g tert-butyl peroxypivalate is added to the reactor, and then Use a high-pressure plunger pump to press carbon dioxide into the reactor to heat the reactor to 80°C. After the reactor pressure reaches 40MPa, after 22 hours of heat preservation polymerization, slowly open the valve to recover carbon dioxide and remaining monomers to obtain poly(vinylidene fluoride- co-perfluoro-n-propyl vinyl ether) macromolecular chain transfer agent;

[0033] Then add 30g of perfluorooctyl ethyl acrylate into the reaction kettle and vacuumize it, add 0.2g of tert-butyl peroxyp...

Embodiment 2

[0036] A method for preparing superhydrophobic fluorine-containing block copolymer microspheres, comprising:

[0037] Vacuumize the 1L reactor to remove moisture and air, pass carbon dioxide and then evacuate, repeat three times; 0.1g perfluoroiodobutane (C 4 f 9 1) chain transfer agent is added in the reactor, then adding 5g mass percent is 5:1 vinylidene fluoride and perfluoro-n-propyl vinyl ether, then 0.02g tert-butyl peroxypivalate is added to the reactor, and then Press carbon dioxide into the reactor with a high-pressure plunger pump, heat the reactor to 60°C, and make the pressure of the reactor reach 10 MPa. After 5 hours of heat preservation polymerization, slowly open the valve to recover carbon dioxide and remaining monomers to obtain poly(vinylidene fluoride) -co-perfluoro-n-propyl vinyl ether) macromolecular chain transfer agent;

[0038]Add 5g of perfluorooctyl ethyl acrylate to the reactor and vacuumize it, add 2g of dibenzoyl peroxide to the reactor, then pr...

Embodiment 3

[0041] A method for preparing superhydrophobic fluorine-containing block copolymer microspheres, comprising:

[0042] The 1L reaction kettle was vacuumized to remove moisture and air, and then carbon dioxide was evacuated, and repeated three times; 10g perfluorooctane iodide (C 8 f 17 1) chain transfer agent is added in the reactor, then adding 100g mass percentage is vinylidene fluoride and perfluoro-n-propyl vinyl ether of 20:1, 5g dibenzoyl peroxide is added to the reactor, and then with a high-pressure plunger The pump presses carbon dioxide into the reactor, heats the reactor to 90°C, and makes the pressure of the reactor reach 40MPa. After 24 hours of thermal insulation polymerization, slowly open the valve to recover carbon dioxide and remaining monomers to obtain poly(vinylidene fluoride-co-perfluoro n-propyl vinyl ether) macromolecular chain transfer agent;

[0043] Add 100g of perfluorooctyl ethyl acrylate to the reactor and vacuumize it, add 5g of dibenzoyl peroxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com