Method for recycling furan ammonium salt from furan ammonium salt waste liquid

A furan ammonium salt and waste liquid technology, applied in the direction of organic chemistry and the like, can solve the problems of high price, a large amount of waste gas, complicated process, etc., and achieve the effects of improving recovery yield, reducing environmental protection pressure, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Weigh 500g of furan ammonium salt waste residue (Z / E=1:7), add 1000mL of ethanol to dilute, add 25g of ferric chloride at the same time, stir and raise the temperature to 80°C, heat and stir for 6 hours, then stop heating, and after the reaction is finished, get The reaction solution is detected by HPLC according to the method of the present invention, Z / E=63 / 37, the reaction solution is purified by the existing separation and purification method, and 265g furan ammonium salt product can be obtained, and the calculated yield is 53%. The product The purity detected by HPLC is ≥99.6%, and the trans-isomer content is ≤0.10%. The product is a white solid, and all indicators fully meet the needs of industrial production.

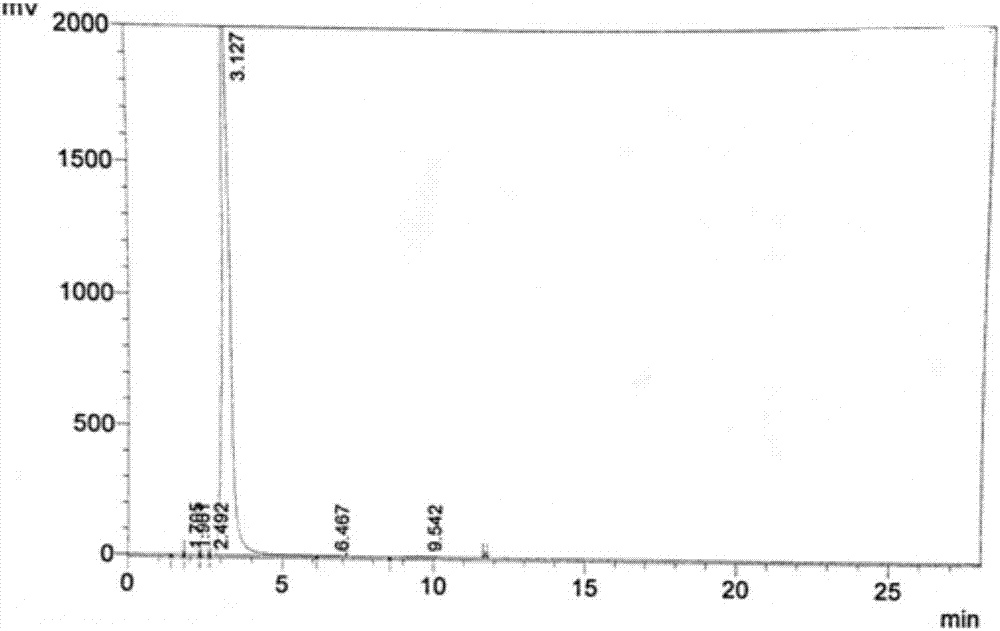

[0054] Measurement results such as figure 1 and figure 2 as shown, figure 1 is the high performance liquid chromatogram of furan ammonium salt; by figure 1 It can be concluded that:

[0055]

[0056]

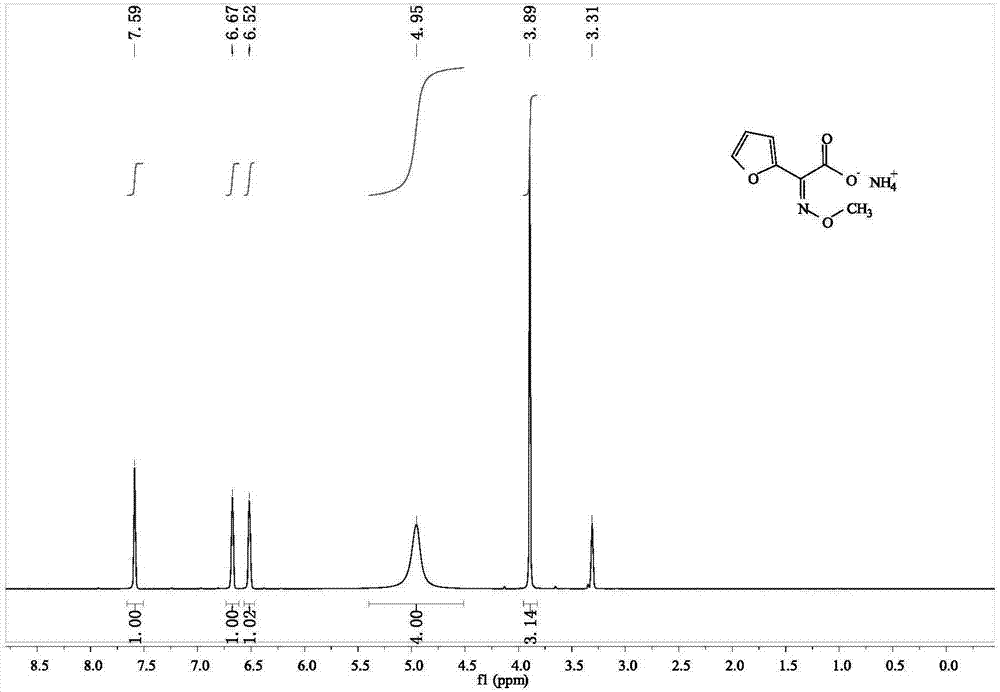

[0057] figure 2 It is the NMR spectrum of...

Embodiment 2

[0059] Weigh 500g of furan ammonium salt waste residue liquid (Z / E=1:7), add 1000mL DMF to dilute, add 5% acetic acid at the same time, stir and raise the temperature to 90°C, heat and stir for 6 hours, then stop heating, and the obtained The reaction solution is detected by HPLC according to the present invention, Z / E=59 / 41, and purified by the existing separation and purification method, 257g furan ammonium salt product can be obtained, the calculated yield is 51%, and the purity of the product is detected by HPLC ≥99.5%, and trans isomer content ≤0.10%, the product is a white solid, and the light transmittance and turbidity of the product fully meet the needs of industrial production.

Embodiment 3

[0061] Weigh 500g of furan ammonium salt waste residue (Z / E=1:7), add 1200mL of DMF to dilute, add 25g of ferric chloride at the same time, stir and raise the temperature to 90°C, heat and stir for 8 hours, stop heating, and get The reaction solution is detected by HPLC according to the method of the present invention, Z / E=69 / 31, the reaction solution is purified by existing separation and purification methods, and 260g of furan ammonium salt product can be obtained, and the calculated yield is 52%. The product The purity detected by HPLC is ≥99.6%, and the trans-isomer content is ≤0.10%. The product is a white solid, and all indicators fully meet the needs of industrial production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com