Low-capacity and high-dispersibility type desulfurization adsorbent for benzol refining and preparation method thereof

It is an adsorbent and highly dispersed technology, which is applied in the direction of adsorption purification/separation, chemical instruments and methods, and other chemical processes. The effect of knot growth, prolonging service life and high desulfurization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

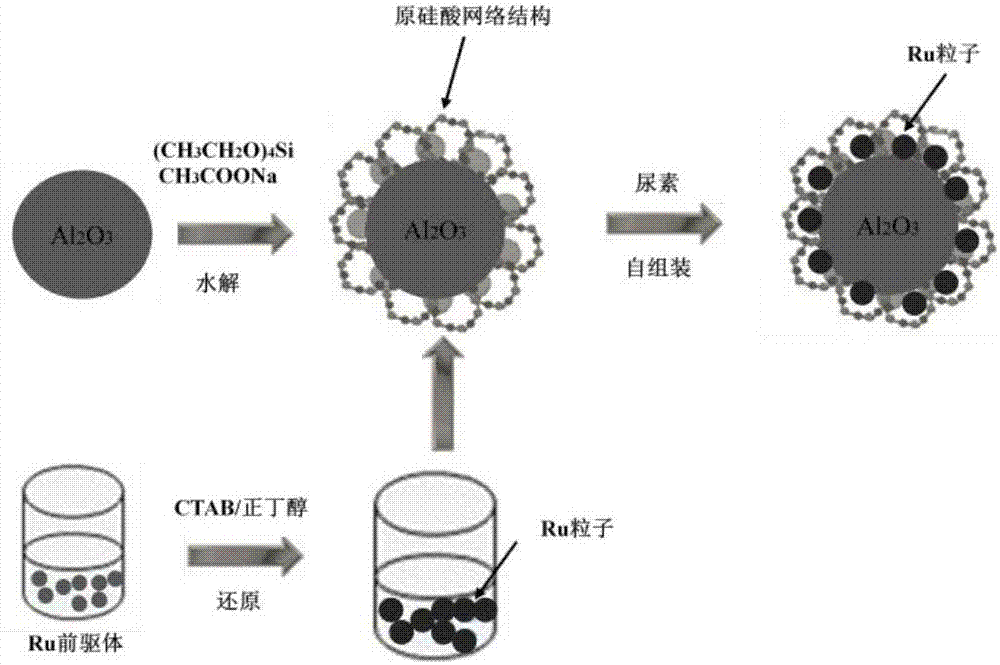

[0024] In the first step, first introduce 50 mL of the prepared 0.15 mol / L ruthenium acetate solution into the reaction tank with stirring, and at the same time add 15 mL of 0.04 mol / L cetyltrimethylammonium bromide, stir for 15 minutes, and then add The reducing agent n-butanol was 100mL, and the mixed solution was added into the autoclave, and treated at 180°C for 12 hours to obtain metal Ru colloid;

[0025] In the second step, mix 1.87g of ethyl silicate and 285mL of 0.1mol / L sodium acetate solution, then add 200g of alumina carrier into the mixed solution under stirring condition, continue stirring at 70°C for 60min, and extract Filter and wash the resulting solid and dry it at 100°C for 12 hours;

[0026] In the third step, by the self-assembly method, the samples obtained in the first and second steps were stirred in 0.01% urea solution for 12 hours, the temperature was 80°C, the nitrogen pressure was 0.05MPa, and the stirring speed was 100r / min, so that the metal Ru s...

Embodiment 2

[0029] In the first step, first introduce 50 mL of the prepared 0.15 mol / L ruthenium nitrate solution into the reaction tank with stirring, and at the same time add 15 mL of 0.04 mol / L cetyltrimethylammonium bromide, stir for 15 min, and then add The reducing agent n-butanol was 100mL, and the mixed solution was added into the autoclave, and treated at 180°C for 12 hours to obtain metal Ru colloid;

[0030] In the second step, mix 1.87g of ethyl silicate and 285mL of 0.1mol / L sodium acetate solution, then add 200g of alumina carrier into the mixed solution under stirring condition, continue stirring at 70°C for 60min, and extract Filter and wash the resulting solid and dry it at 100°C for 12 hours;

[0031] In the third step, by the self-assembly method, the samples obtained in the first and second steps were stirred in 0.01% urea solution for 12 hours, the temperature was 80°C, the nitrogen pressure was 0.05MPa, and the stirring speed was 100r / min, so that the metal Ru stabl...

Embodiment 3

[0034] In the first step, first introduce 50 mL of the prepared 0.15 mol / L ruthenium acetate solution into the reaction tank with stirring, and at the same time add 15 mL of 0.04 mol / L cetyltrimethylammonium bromide, stir for 15 minutes, and then add The reducing agent n-butanol is 75mL, and the mixed solution is added into the autoclave, and treated at 180°C for 12h to obtain metal Ru colloid;

[0035] In the second step, mix 1.87g of ethyl silicate and 285mL of 0.1mol / L sodium acetate solution, then add 200g of alumina carrier into the mixed solution under stirring condition, continue stirring at 70°C for 60min, and extract Filter and wash the resulting solid and dry it at 100°C for 12 hours;

[0036] In the third step, by the self-assembly method, the samples obtained in the first and second steps were stirred in 0.01% urea solution for 12 hours, the temperature was 80°C, the nitrogen pressure was 0.05MPa, and the stirring speed was 100r / min, so that the metal Ru stably an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com