Cocoa polyphenol extraction and enrichment preparation method

A technology for enrichment and extraction, which is applied in the field of extraction technology and macroporous resin purification technology, can solve the problems of low utilization, high cost, and low recovery rate of cocoa polyphenols, and achieve simple process flow, improved recovery rate and Content, suitable for industrial amplification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

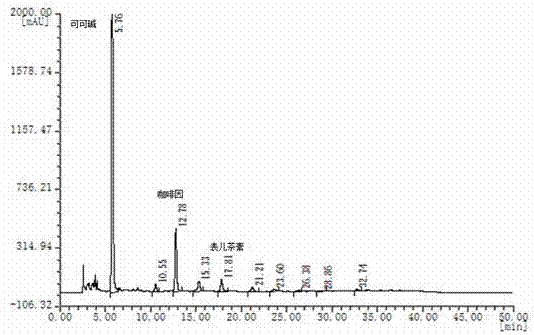

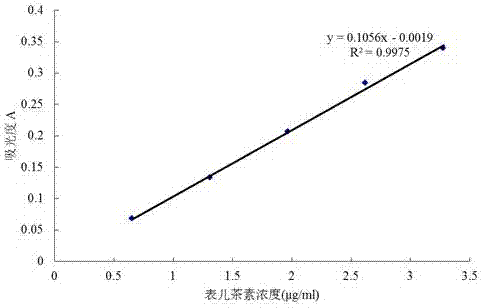

Image

Examples

Embodiment 1

[0030] Extraction of cocoa polyphenols: crush 100.0 g of unfermented and unroasted cocoa beans. According to the solid-liquid ratio of 1:5, 20% ethanol solution was added to the crushed cocoa beans, heated to 70°C and stirred for 1 h, the extraction was repeated twice, and the extracts were combined. Concentrate the extract under reduced pressure to remove the solvent ethanol, dilute with water to a concentration of 6 mg / ml sample solution, and centrifuge to remove insoluble matter in the filtrate.

[0031] Sample loading adsorption: wash the pretreated LX-17 macroporous resin with pure water for 3 BV (column bed volume, the same below), add cocoa bean sample solution, and the sample loading speed is 1.6 BV / h for adsorption. After loading the sample, rinse the column 2 BV with pure water. Collect the effluent and pure water eluate.

[0032] Gradient elution: After the LX-17 resin is loaded and adsorbed, it is eluted with 10% ethanol solution for 3 BV, 50% ethanol solution fo...

Embodiment 2

[0035] Extraction of cocoa polyphenols: crush 100.0 g of unfermented and unroasted cocoa beans. Add 70% ethanol solution to the crushed cocoa beans according to the solid-liquid ratio of 1:30, heat to 75°C and stir for leaching for 3 h, repeat the extraction 3 times, and combine the extracts. Concentrate the extract under reduced pressure to remove the solvent ethanol, dilute with water to a concentration of 6 mg / ml sample solution, and centrifuge to remove insoluble matter in the filtrate.

[0036] Sample loading and adsorption: Rinse the pretreated LX-17 macroporous resin with pure water for 3 BV, add cocoa bean sample solution, and the sample loading speed is 1.6 BV / h for adsorption. After loading the sample, wash the column with pure water for 1 BV. Collect the effluent and pure water eluate.

[0037] Gradient elution: After the LX-17 resin is loaded and adsorbed, it is eluted with 10% ethanol solution for 5 BV, 50% ethanol solution for 8 BV, 90% ethanol solution for 4 B...

Embodiment 3

[0040] Extraction of cocoa polyphenols: 2.0 kg of unfermented and unroasted cocoa shells were pulverized. According to the solid-liquid ratio of 1:10, 50% ethanol solution was added to the pulverized cocoa shell, heated to 80°C and stirred for 1.5 h, and the extraction was repeated 3 times, and the extracts were combined. Concentrate the extract under reduced pressure to remove the solvent ethanol, dilute with water to a concentration of 6 mg / ml sample solution, and centrifuge to remove insoluble matter in the filtrate.

[0041] Sample loading adsorption: Rinse the pretreated LX-17 macroporous resin with pure water for 2 BV, add cocoa shell sample solution, and the sample loading speed is 1.6 BV / h for adsorption. After loading the sample, rinse the column 2 BV with pure water. Collect the effluent and pure water eluate.

[0042] Gradient elution: After the LX-17 resin is loaded and adsorbed, it is eluted with 10% ethanol solution for 4 BV, 50% ethanol solution for 6 BV, 90% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com