Self-repairing polyurethane resin raw material, self-repairing polyurethane resin, self-repairing coating material, self-repairing elastomeric material, self-repairing polyurethane resin raw material production method and self-repairing polyurethane resin production method

A polyurethane resin, self-healing technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of brittleness, high hardness, inability to prevent indentation damage, etc., and achieve excellent balance, weather resistance and light resistance. Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

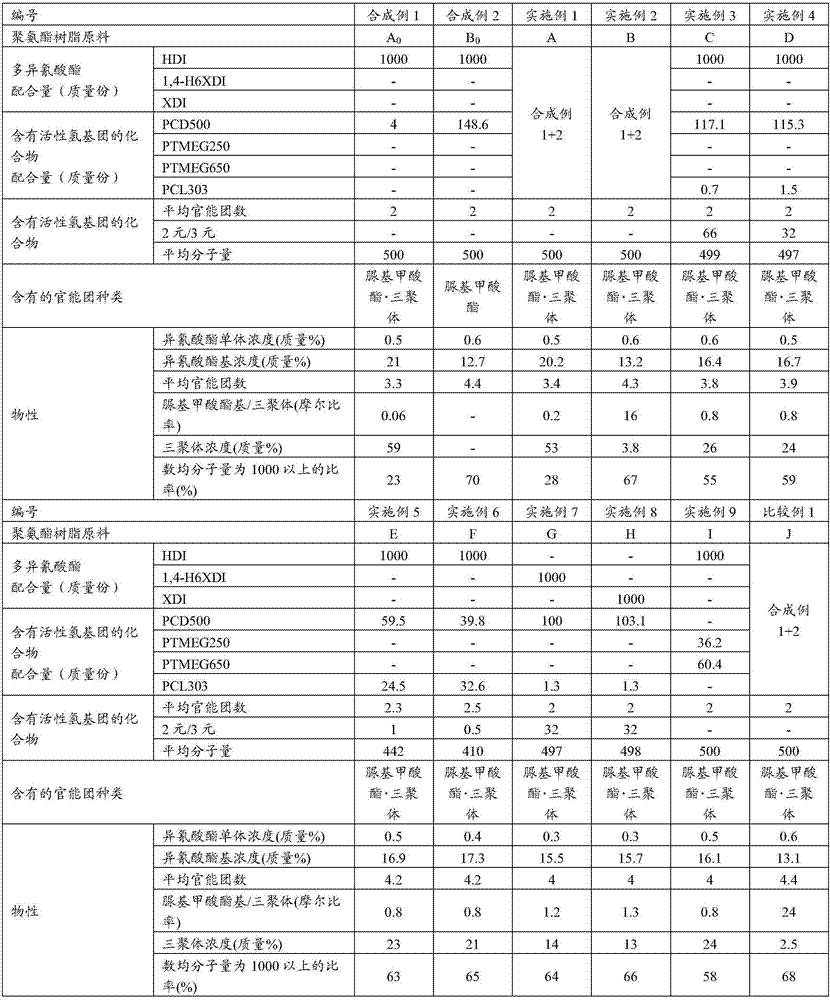

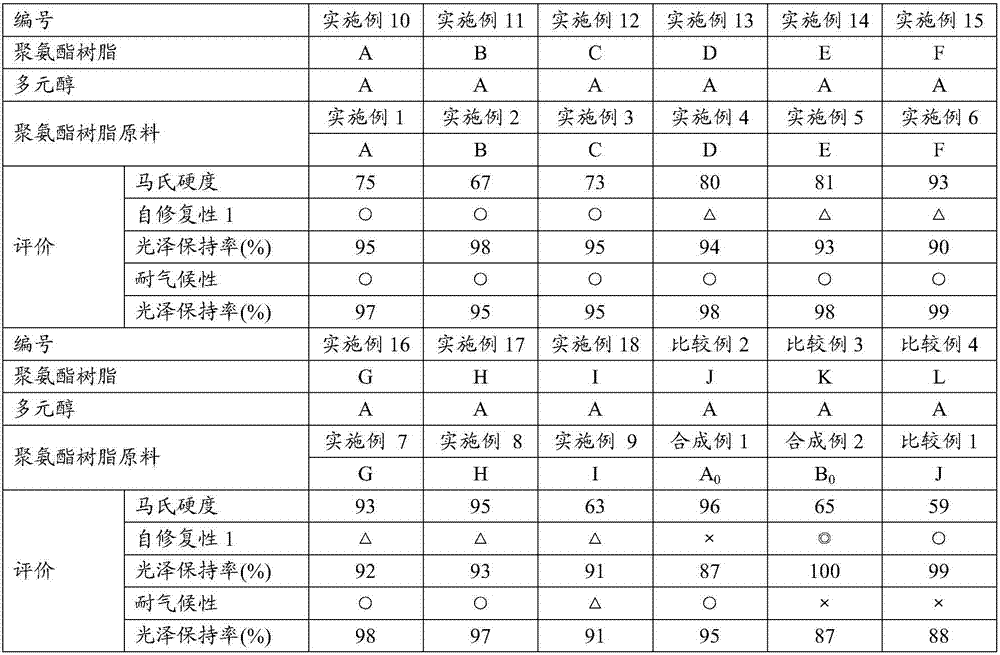

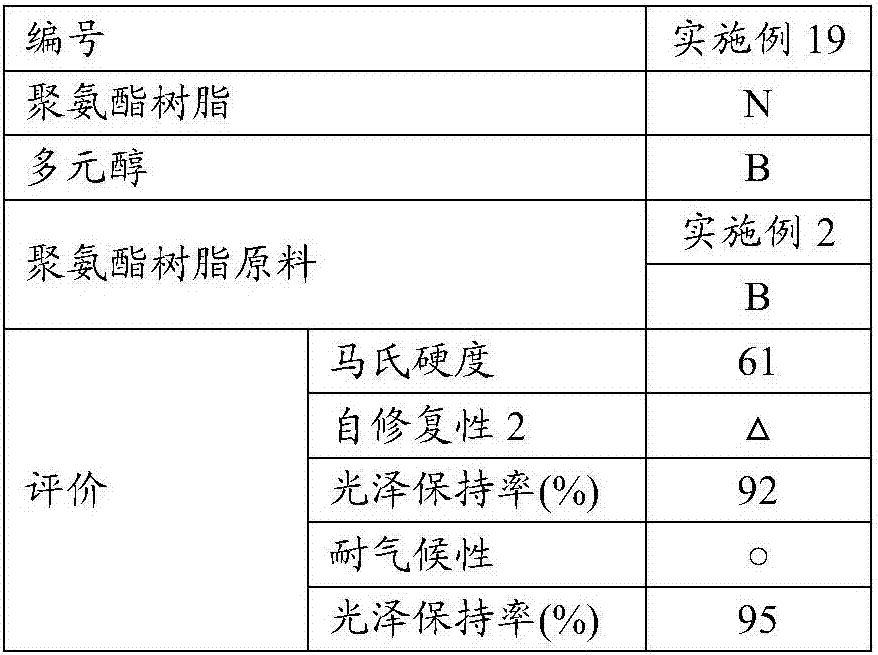

[0326] Hereinafter, although an Example and a comparative example are given and this invention is demonstrated in detail, this invention is not limited to these examples. In addition, in the following description, unless otherwise specified, "part" and "%" are based on mass. In addition, the numerical value of the Example shown below can be replaced with the numerical value (namely, upper limit value or lower limit value) described in embodiment.

[0327] In addition, the measurement methods used in each Example and each comparative example are as follows.

[0328]

[0329] Isocyanate monomers (polyisocyanate compounds, specifically, 1,6-hexamethylene diisocyanate, 1,4-bis(isocyanatomethyl)cyclohexane, or m-xylylene diisocyanate) were used as standard substances , using a calibration curve prepared from the area value of the chromatogram obtained under the following HPLC analysis conditions, the concentration of unreacted isocyanate monomer in the polyurethane resin raw mat...

manufacture example 1

[0378] Production Example 1 (production of 1,4-bis(aminomethyl)cyclohexane)

[0379] By the same operation as in Example 1 described in paragraph numbers [0132] to [0147] in the specification of International Publication No. WO2012 / 046782, a trans-isomer / cis-isomer=88 / 12 (molar ratio) was obtained. 1,4-Bis(aminomethyl)cyclohexane.

manufacture example 2

[0380] Production Example 2 (production of 1,4-bis(isocyanatomethyl)cyclohexane)

[0381] Except that the 1,4-bis(aminomethyl)cyclohexane obtained in Production Example 1 was used, the method described in paragraph numbers [0225] to [0229] in the specification of International Publication Pamphlet WO2009 / 051114 The same operation of Production Example 1 was carried out to obtain 1,4-bis(isocyanatomethyl)cyclohexane (hereinafter sometimes referred to as 1,4- BIC). In addition, the purity measured by gas chromatography was 99.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com