A kind of water-based coating containing graphene/zinc-aluminum hydrotalcite nanocomposite and preparation method thereof

A zinc-aluminum hydrotalcite and nanocomposite technology, applied in the field of coatings, can solve the problems of unbalanced VOC content and physical properties, reduced physical properties of coatings, limited improvement in corrosion resistance, etc., and achieves strong practical value and extended use. Long life and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

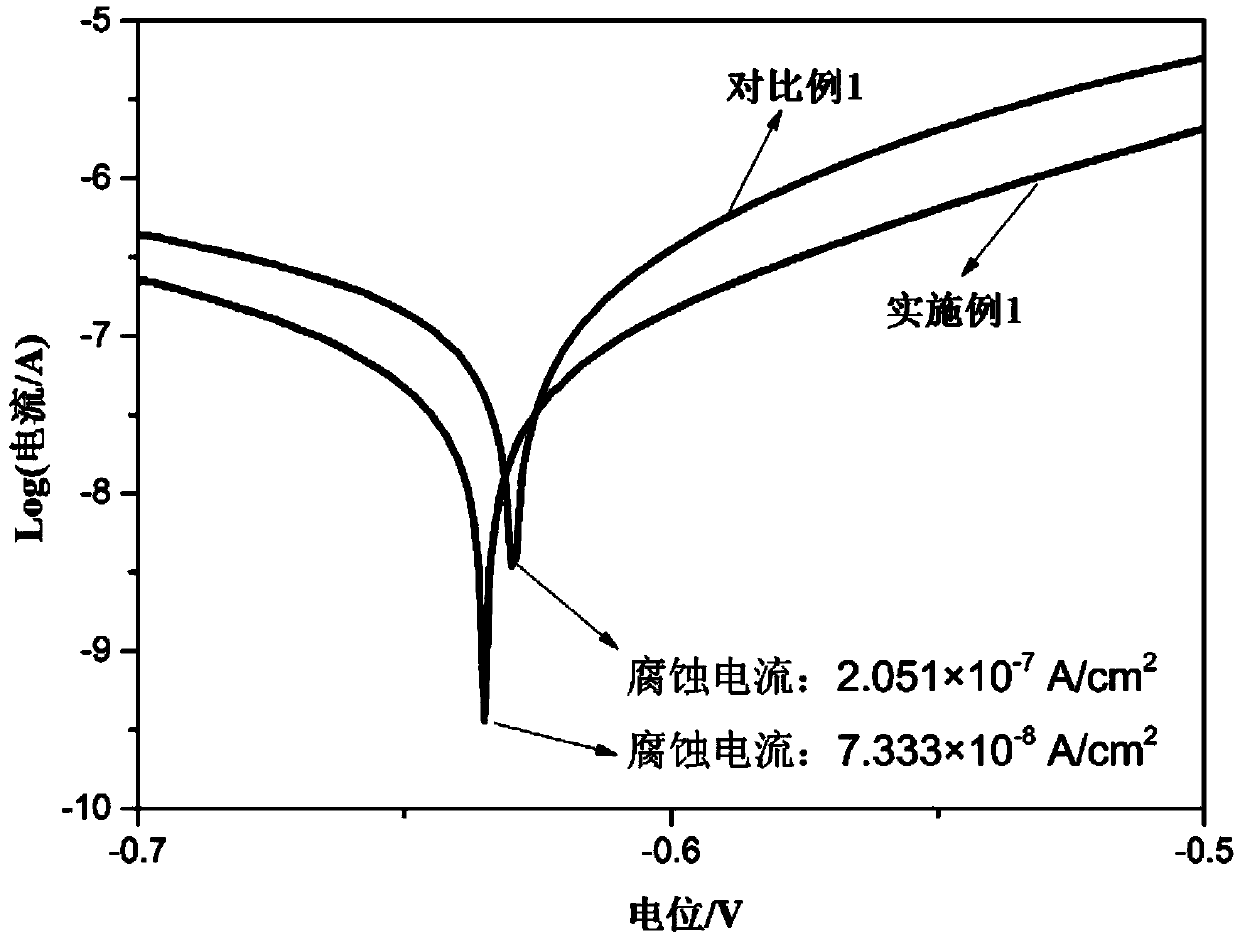

Embodiment 1

[0054] 1. Preparation of graphene / zinc-aluminum hydrotalcite nanocomposites:

[0055] 1) Disperse 100 mg of graphene oxide in ethylene glycol aqueous solution (50 g of ethylene glycol + 50 g of deionized water), and ultrasonically treat at 30°C for 30 minutes to obtain a graphene solution; 2.2 g of zinc nitrate hexahydrate, 1.1 g of nine Aluminum nitrate in water and 11.5g urea were dissolved in 20ml water to obtain zinc-aluminum hydrotalcite precursor solution; 1.0g coupling agent (3-aminopropyltriethoxysilane) was dissolved in ethylene glycol aqueous solution (49.5g B Glycol+49.5g deionized water), adjust the pH of the solution to be 4, stir for two hours, the coupling agent is fully hydrolyzed, and the coupling agent hydrolyzate is obtained;

[0056] 2) Add the zinc-aluminum hydrotalcite precursor solution dropwise to the graphene solution for about 4 hours, then react at 100°C and pH 8 for 24 hours, complete the reaction, and centrifuge the reaction solution. The separate...

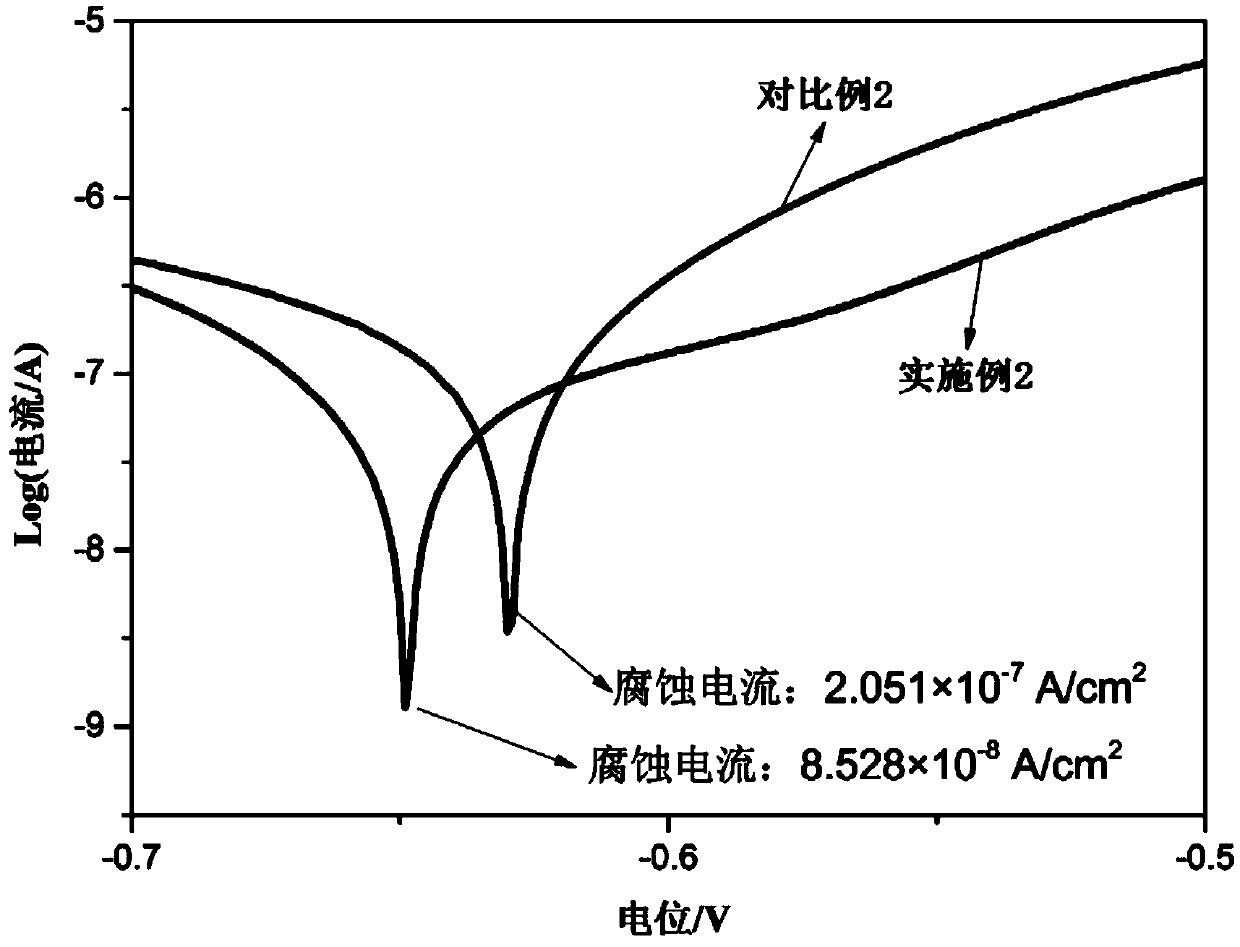

Embodiment 2

[0070] 1. Preparation of graphene / zinc-aluminum hydrotalcite nanocomposites:

[0071] 1) Disperse 250 mg of graphene oxide in an aqueous solution of ethylene glycol (50 g of ethylene glycol + 50 g of deionized water), and ultrasonically treat it at 30°C for 60 minutes to obtain a graphene solution; 2.2 g of zinc nitrate hexahydrate, 1.1 g of nine Aluminum nitrate in water and 15g urea were dissolved in 30ml water to obtain zinc-aluminum hydrotalcite precursor solution; 1.5g coupling agent (3-aminopropyltriethoxysilane) was dissolved in ethylene glycol aqueous solution (49g ethylene glycol +49.5g deionized water), adjust the pH of the solution to be 4, stir for two hours, make the coupling agent fully hydrolyzed, and obtain the coupling agent hydrolyzate;

[0072] 2) Add the zinc-aluminum hydrotalcite precursor solution dropwise to the graphene solution for about 5 hours, then react at 100°C and pH value of 8.5 for 24 hours, end the reaction, and centrifuge the reaction solutio...

Embodiment 3

[0086] 1. Preparation of graphene / zinc-aluminum hydrotalcite nanocomposites:

[0087] 1) Disperse 150 mg of graphene oxide in an aqueous solution of ethylene glycol (50 g of ethylene glycol + 50 g of deionized water), and perform ultrasonic treatment at 30°C for 50 minutes to obtain a graphene solution; 2.2 g of zinc nitrate hexahydrate, 1.1 g of nine Aluminum nitrate in water and 12.5g urea were dissolved in 30ml water to obtain zinc-aluminum hydrotalcite precursor solution; 1.0g coupling agent (3-aminopropyltriethoxysilane) was dissolved in ethylene glycol aqueous solution (49.5g Glycol+49.5g deionized water), adjust the pH of the solution to be 4, stir for two hours, the coupling agent is fully hydrolyzed, and the coupling agent hydrolyzate is obtained;

[0088] 2) Add the zinc-aluminum hydrotalcite precursor solution dropwise to the graphene solution for about 5 hours, then react for 24 hours at 100°C and a pH value of 8.3, finish the reaction, and centrifuge the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com