An agricultural peanut harvesting machine for separating and harvesting peanut seedlings

A technology for peanut harvesting and peanut seedling, which is applied in the fields of excavator harvesters, agricultural machinery and implements, agriculture, etc., can solve the problems of pig impact, film removal, and increase in breeding costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

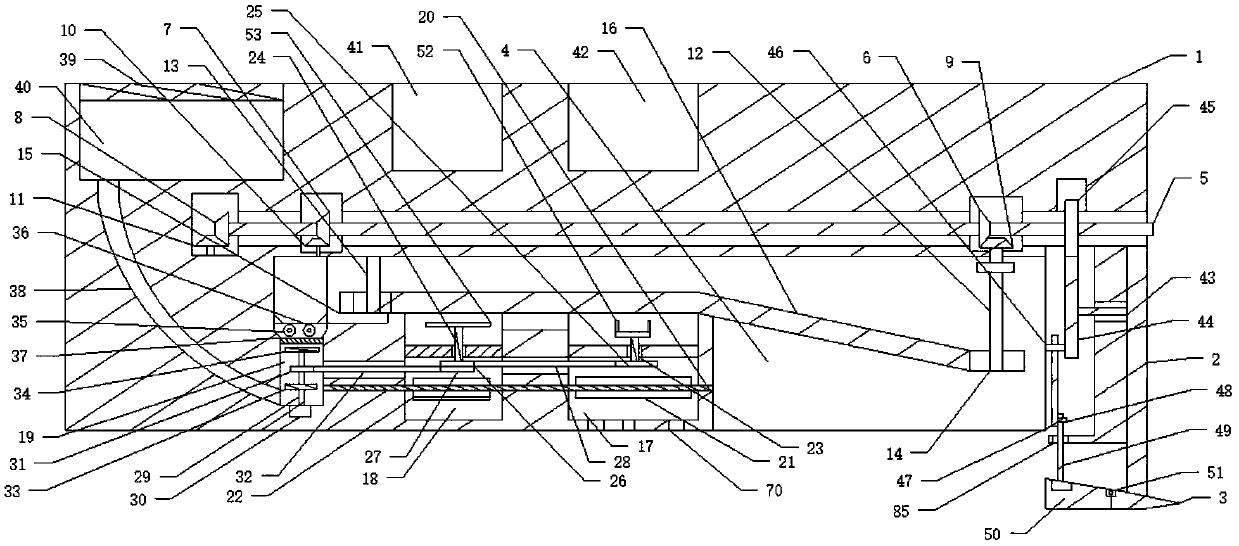

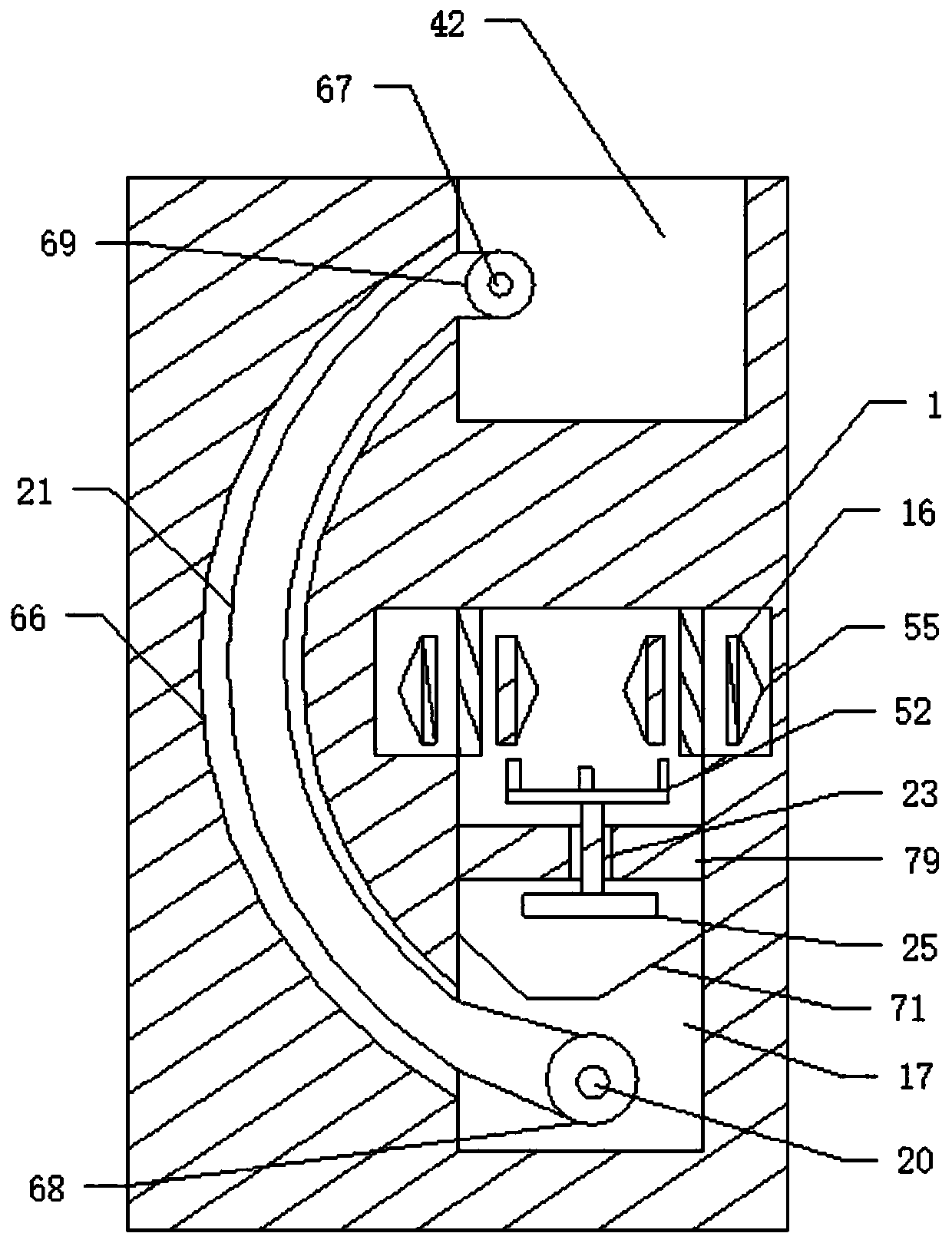

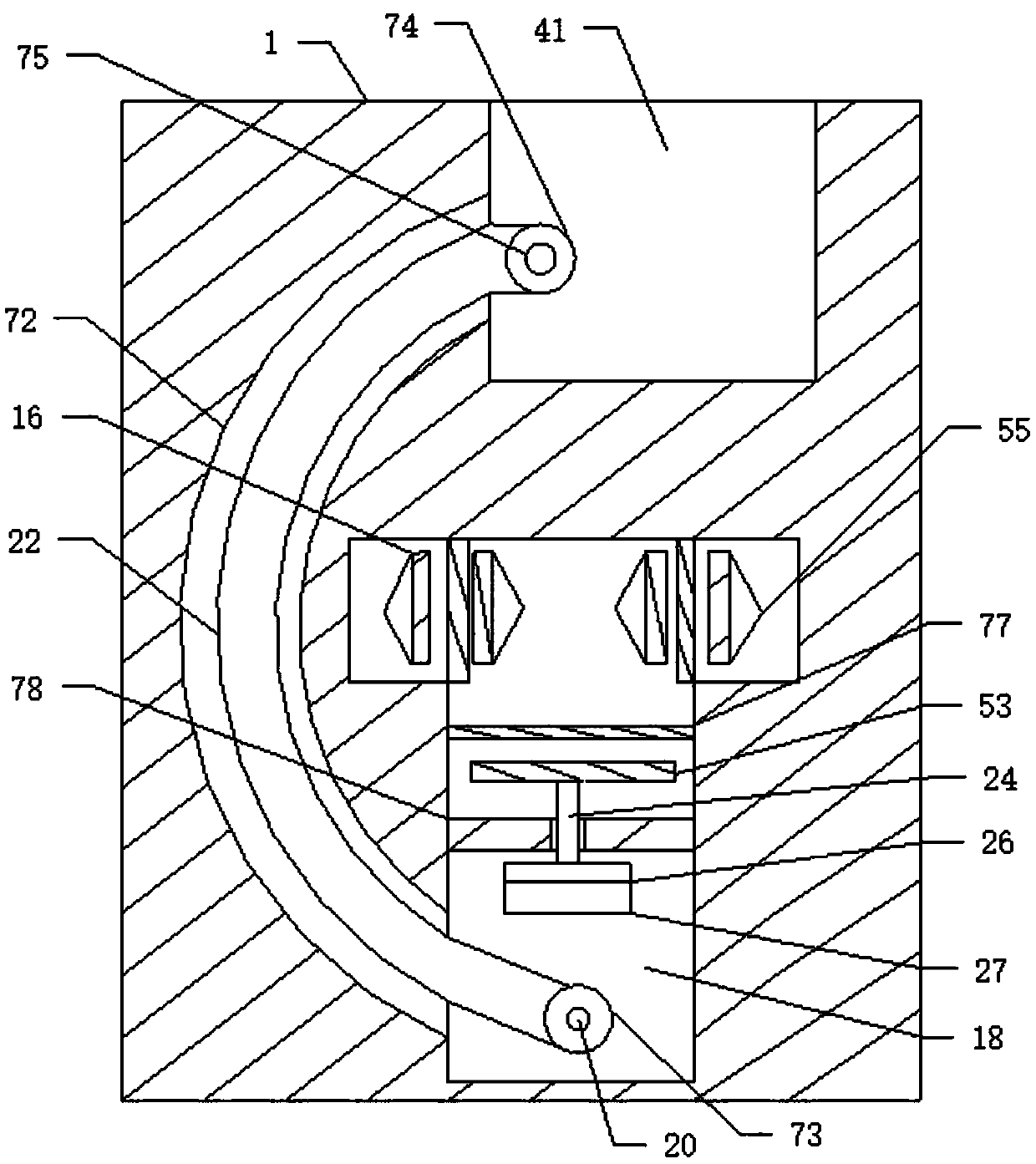

[0037] Such as Figure 1 to Figure 11 As shown, an agricultural peanut harvesting peanut seedling separation harvester includes a body 1. The bottom of the body 1 is provided with a harvesting groove 4. The two sides of the body 1 are respectively connected with a harvesting support frame 2. The harvesting supports on both sides The frame 2 is correspondingly connected with a harvesting bottom knife 3 corresponding to the harvesting trough 4 , and a swinging swinging bottom knife 50 is arranged on the harvesting bottom knife 3 . A concave harvesting trough 4 is arranged at the bottom of the body 1, and two corresponding harvesting support frames 2 are also provided at the end of the body 1, and the two harvesting support frames 2 are correspondingly connected to the On both sides of the body 1, a harvesting bottom knife 3 is correspondingly connected to the harvesting support frame 2 on both sides, and the harvesting bottom knife 3 corresponds to the harvesting groove 4, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com