Projector calibration method and apparatus

A projector and projection technology, which is applied in the direction of instruments, image data processing, calculation, etc., can solve the problems of low accuracy and low efficiency of the calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

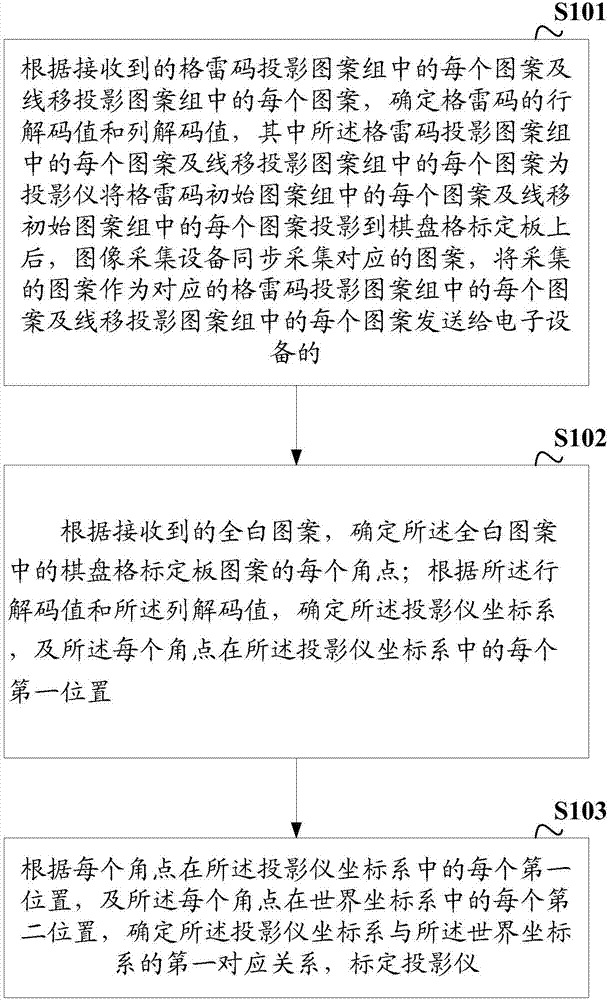

[0058] figure 1 A schematic diagram of a projector calibration method provided by an embodiment of the present invention, the method includes the following steps:

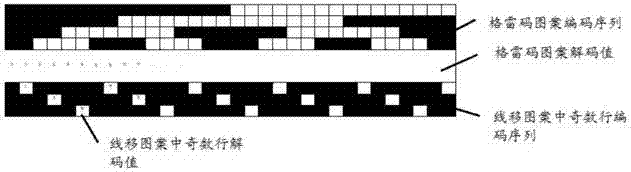

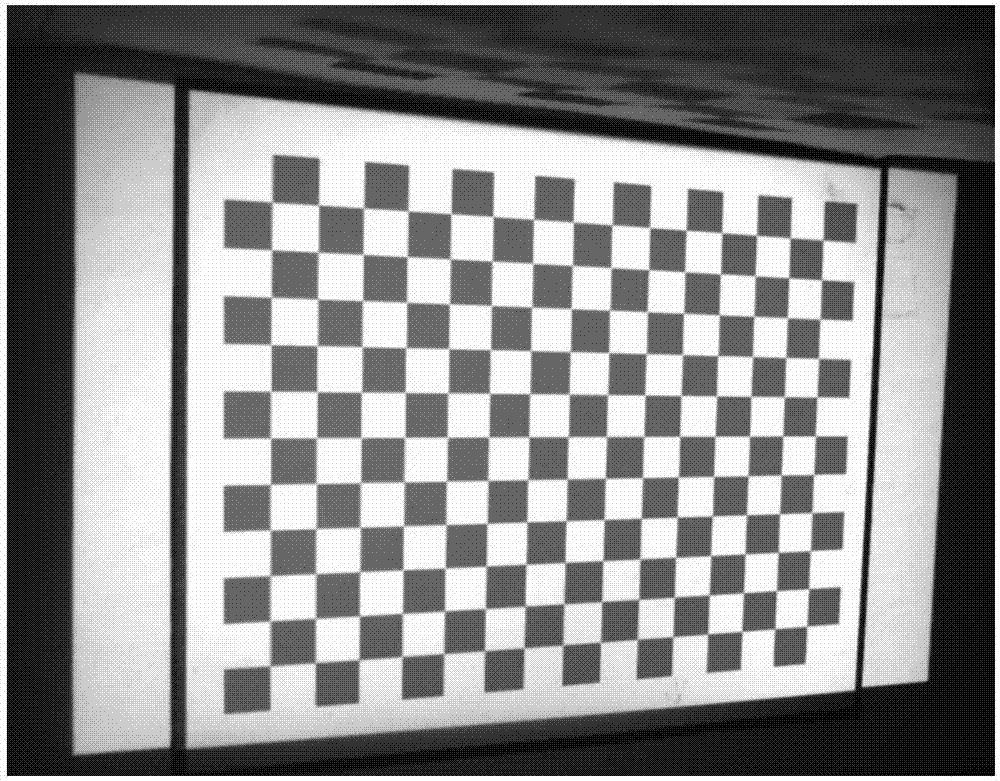

[0059] S101: According to each pattern in the received Gray code projection pattern group and each pattern in the line-shift projection pattern group, determine the row decoding value and column decoding value of the Gray code, wherein the Gray code projection pattern group Each pattern and each pattern in the line-shift projection pattern group is after the projector projects each pattern in the Gray code initial pattern group and each pattern in the line-shift initial pattern group to the checkerboard calibration board, image acquisition The device collects the corresponding pattern, and sends the collected pattern to the electronic device as each pattern in the corresponding Gray code projection pattern group and each pattern in the line shift projection pattern group.

[0060] The projector calibration method ...

Embodiment 2

[0080] The Gray code initial pattern group can be saved in the projector in advance, in order to ensure the consistency of the Gray code initial pattern group in the electronic device and the projector, on the basis of the above-mentioned embodiments, in the embodiment of the present invention, the receiving Gray code Each pattern in the code projection pattern set includes:

[0081] According to the locally saved Gray code pattern generation rules, generate each pattern in the Gray code initial pattern group, wherein each pattern in the Gray code initial pattern group includes a line Gray code initial pattern, a reverse row Gray code initial pattern, Column Gray code initial pattern and reverse column Gray code initial pattern;

[0082] Send each pattern in the gray code initial pattern group to the projector, so that after the projector projects each pattern in the gray code initial pattern group onto the checkerboard calibration board, the image acquisition device synchrono...

Embodiment 3

[0089] In order to further ensure the accuracy of the line decoding value and the decoding value of the Gray code, and improve the calibration efficiency, on the basis of the above-mentioned embodiments, in the embodiment of the present invention, each pattern in the receiving line-shifting projection pattern group includes:

[0090] Delete the even-numbered rows in the row-line-shift initial pattern and the column-line-shift initial pattern according to the row-line-shift initial pattern and column-line-shift initial pattern in the pre-saved line-shift initial pattern group;

[0091] Sending the initial row line shift pattern and column line shift initial pattern after deleting even-numbered rows to the projector, so that the projector projects the row line shift initial pattern and column line shift initial pattern after deleting even-numbered rows onto a checkerboard grid After the plate is calibrated, the image acquisition device collects the corresponding pattern, and send...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com