Straight-down type LED panel lamp

A technology of LED panel lights and LED lamp beads, which is applied in lighting and heating equipment, semiconductor devices of light-emitting elements, refractors, etc., can solve the problems of high light source density, high manufacturing accuracy, and complicated procedures, and achieve low-cost lighting Density, improve uniformity, increase the effect of mixing light distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

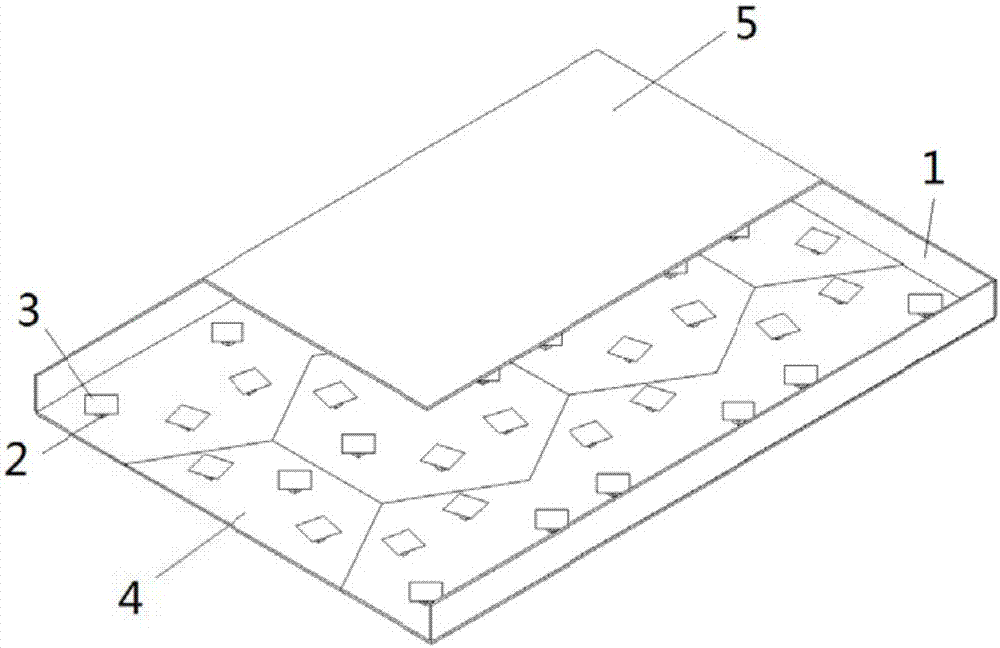

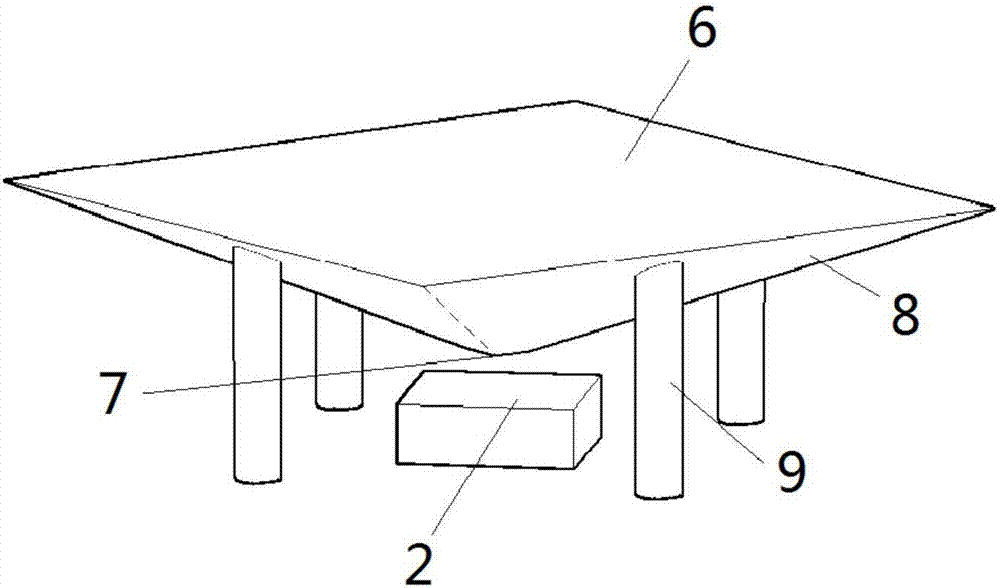

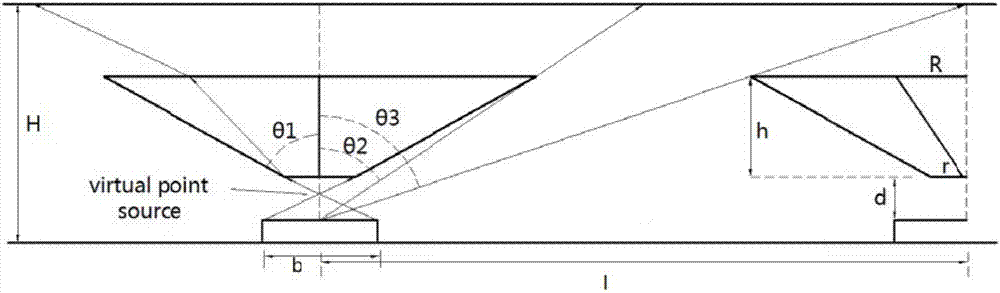

[0032] This embodiment discloses a high-uniformity ultra-thin direct-lit LED flat panel lamp, such as figure 1 As shown, it includes housing 1, LED2, light mixing element 3, diffuse reflection bottom plate 4 and light output panel 5 and other structures, and the structure of a single light mixing element is as follows figure 2 As shown, it includes structures such as an upper bottom surface 6, a lower bottom surface 7, a reflective surface 8 and a transparent bracket 9. The LEDs are arranged in a hexagonal array on the diffuse reflection base plate, and a light mixing element is installed above each LED by a transparent bracket. The light mixing element is formed by injection molding process. After protecting the upper and lower light-transmitting surfaces, vacuum evaporation is used to aluminize the reflective surface, and finally the light-transmitting surface is polished to make it transparent. The size of the whole lamp is a cube of 271mm*191mm*17, the shape of the light...

Embodiment 2

[0036] The shape of the light mixing element used in this embodiment is a truncated cone, and other structures are the same as those in the embodiment. The size of the whole lamp is 271mm*191mm*17mm. The structure of the light mixing element is as follows Figure 4 As shown, it includes an upper bottom surface 10, a lower bottom surface 11, a reflective surface 12 and a transparent bracket 13 and other structures. The radius of the upper bottom surface of the frustum-shaped light mixing element is 6mm, the radius of the lower surface is 0.35mm, the thickness of the element is 2.5mm, the height between the element and the LED is 0.7mm, the distance between the LEDs is 35mm, and the internal height of the lamp is 15mm. Through the ray simulation software Tracepro simulation, the uniformity of the light emitting surface of the lamp is 95.30%, and the light efficiency is 92.97%.

Embodiment 3

[0038] The shape of the light mixing element used in this embodiment is hemispherical, and the hemispherical light mixing element is an intercepted part of a sphere. The light mixing element structure is as Figure 5 As shown, it includes structures such as an upper bottom surface 14, a lower bottom surface 15, a reflective surface 16 and a transparent bracket 17. The radius of the upper bottom surface is 4mm, the radius of the lower bottom surface is 0.6mm, the thickness of the component is 3.0mm, the height between the component and the LED is 0.7mm, the distance between the LEDs is 35mm, and the internal height of the lamp is 15mm. Through the optical simulation tracking software Tracepro simulation, the uniformity of the light emitting surface of the lamp is 97.47%, and the light efficiency is 92.97%.

[0039] The above three kinds of light mixing elements are all formed by injection molding combined with vacuum evaporation, and the upper and lower bottom surfaces are lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com