Water-permeable type facing bricks and installation method thereof

A technology of surface bricks and water seepage holes, which is applied to pavement details, pavements paved with prefabricated blocks, and adaptation to climate change. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

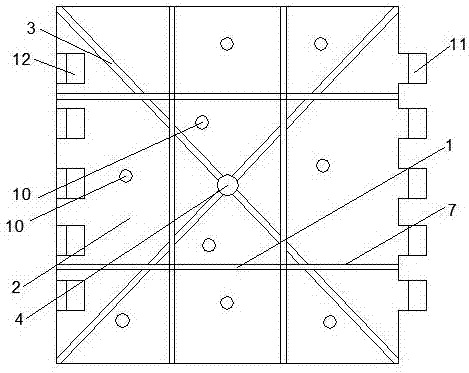

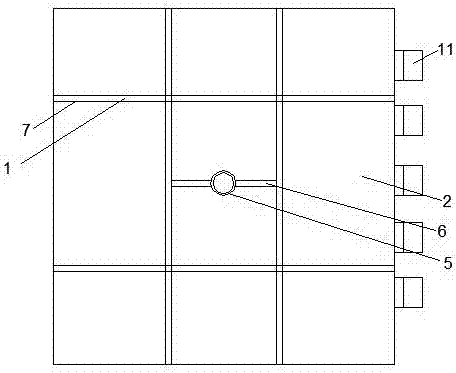

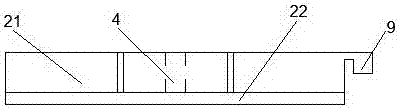

[0031] figure 1 , figure 2 , image 3 Shown is a water seepage face brick, which includes a reinforcement frame 1 and a face brick body 2, the above face brick body 2 is arranged inside the reinforcement frame 1, the inner side of the reinforcement frame 1 is close to the surface of the face brick body 2, and the upper bottom surface of the face brick body 2 is open. There is a water guide groove 3, the bottom of the water guide groove 3 is set downward from the beginning end to the end, and the end of the water guide groove 3 is provided with a water seepage hole 4, and the above-mentioned face brick main body 2 is divided into a permeable part 21 and a water collection part in turn from top to bottom 22. The water collecting part 22 is a hollow cavity, and the above-mentioned water seepage hole 4 runs through the water permeable part 21 along the vertical direction, and the bottom of the water collecting part 22 is also provided with a water outlet hole, and the bottom of ...

specific Embodiment 2

[0034] This embodiment is a detailed description of the raw materials for making the water-permeable part 21 on the basis of the specific embodiment 1. The above-mentioned water-permeable part 21 is made of the following raw materials in parts by weight: 67-80 parts of steel slag, 15 parts of hard plastic powder -22 parts, 7-16 parts of cement, 10-13 parts of activated carbon and 6-9 parts of orange peel powder.

[0035] The permeable part is made of steel slag and hard plastic powder as the main raw materials. These two materials are waste materials, and the production cost is low. Moreover, the use of waste materials can effectively reduce the pollution of waste materials to the environment. Since steel slag and hard plastic are used in the production Toxic substances will be released during the process, so activated carbon is added to absorb the released toxic substances, and orange peel powder can deodorize and purify the odor. The main components of air pollution are sulfu...

specific Embodiment 3

[0037]This embodiment further illustrates the raw materials for making the permeable part 21 on the basis of specific embodiment 2. The particle diameter of the above-mentioned steel slag is greater than 1.4mm, and the particle diameter of the hard plastic powder is less than 1.2mm. The method for making the permeable body is as follows: The steel slag, hard plastic powder, cement, activated carbon and orange peel prepared in proportion are mixed and formed by vibration forming method.

[0038] The large particle size of the steel slag makes the pores of the permeable part larger, and the water can penetrate quickly, while the particle size of the hard plastic is small, and can form smaller pores, so that the water can flow downward at a uniform speed after permeating into the permeable part 21, so that The outfall can also drain water at a uniform speed, reducing the impact on the original soil layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com