Method for preparing synthetic sapphire by micro-pulling and shoulder-expanding at cooled center

A technology for sapphire and sapphire crystals, which is applied in the direction of self-melt pulling method, chemical instruments and methods, single crystal growth, etc., which can solve the problems of easy contamination of crystals, easy occurrence of bubbles, high cost, etc., to ensure the quality of single crystal growth , Prevent crystal cracking and reduce growth cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

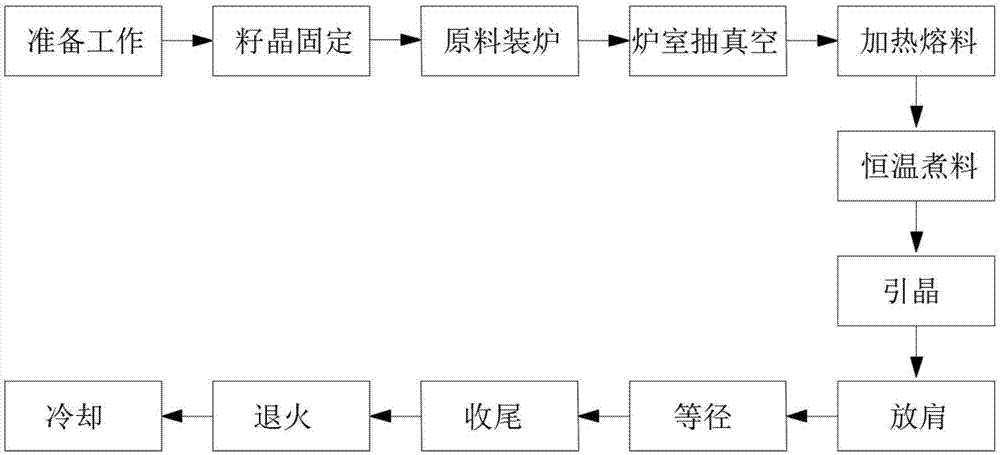

[0036] Example 1, such as figure 1 Shown:

[0037] A kind of preparation method that is used for artificial sapphire cold shoulder lifting, comprises the steps:

[0038] (1) Preparatory work: Before pulling and preparing sapphire crystals, it is necessary to thoroughly check whether there are foreign objects or impurities in the furnace, and clean them up; because during the crystal growth process, impurities or foreign objects in the furnace will be destroyed by high temperature. Cause crystals to be polluted, thereby affecting the quality of crystals; by cleaning up impurities in the furnace before pulling preparation, the possibility of impurity precipitation can be effectively reduced;

[0039] (2) Seed crystal fixation: fix the wedge-shaped columnar seed crystal on the crystal pulling rod with thin tungsten wire, and place it at the bottom of the heat exchanger; when the columnar seed crystal is installed, the wedge-shaped top is fixed by tungsten wire , the wedge-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com