Electrolytic corrosive agent and corrosion method for displaying metallographic structure of high-purity aluminum

A metallographic structure and electrolytic corrosion technology, applied in the field of metallographic electrolytic corrosion, can solve the problems of high experimental cost, poor display effect, and poor versatility, and achieve the effect of cheap price, simple composition, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

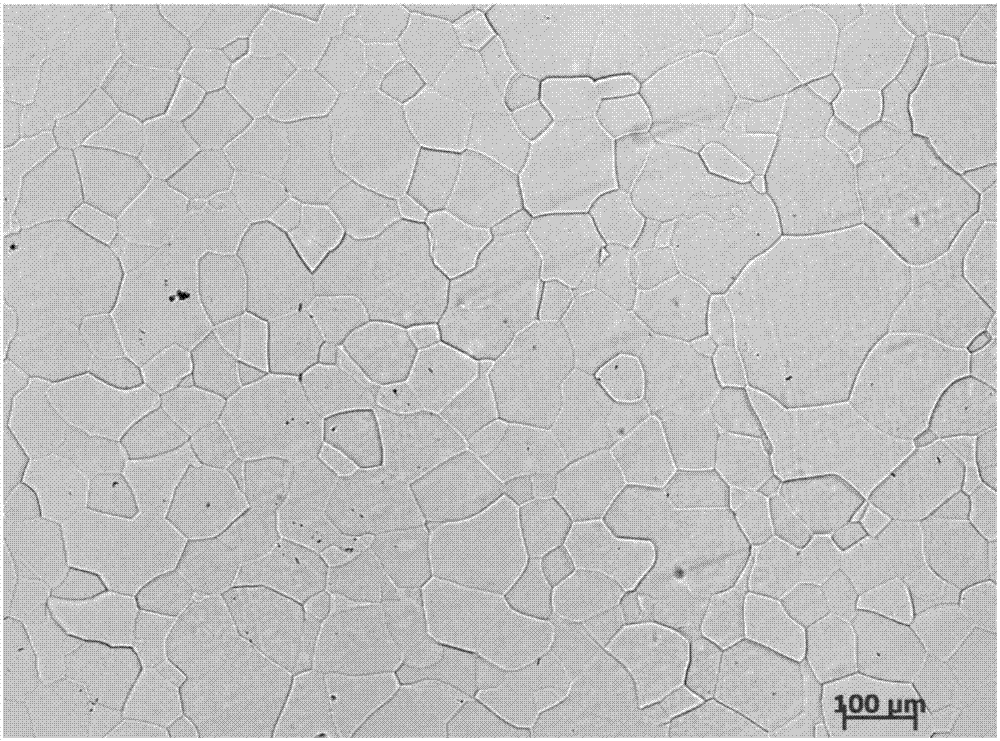

Embodiment 1

[0024] An electrolytic etchant and a corrosion method for displaying the metallographic structure of 6N high-purity aluminum include the following steps:

[0025] (1) Surface cleaning of the sample before electrolytic corrosion: Rinse the polished sample with alcohol, the size of the sample is 16mm×18mm×5mm, and dry it with a hair dryer with cold air to ensure that the surface of the sample is free of dust and other pollutants;

[0026] (2) Preparation of electrolytic etchant: the composition of the etchant includes 18ml of hydrogen fluoride solution, 2.6g of boric acid, and 200ml of distilled water with a volume fraction of 40%. Pour distilled water, hydrogen fluoride solution, and boric acid into a clean container successively at room temperature, and stir until the boric acid Dissolve completely, and use after standing at a temperature lower than room temperature (20°C) for 20 minutes;

[0027] (3) Electrolytic corrosion: Turn on the DC power supply, adjust the voltage to 8...

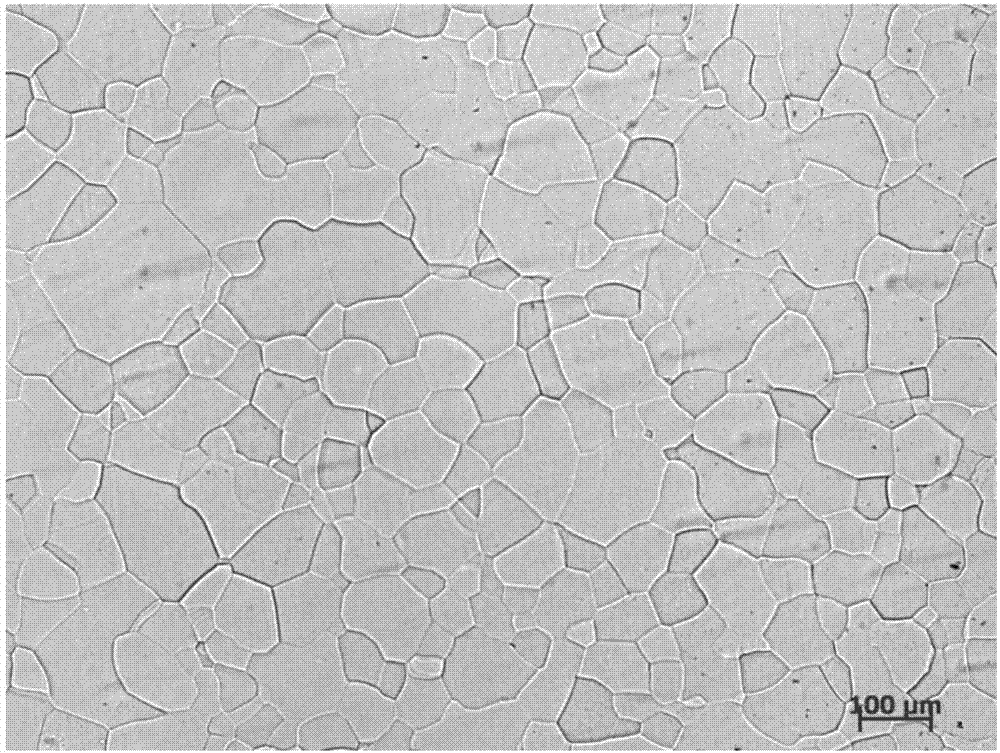

Embodiment 2

[0031] An electrolytic etchant and a corrosion method for displaying the metallographic structure of 5N5 high-purity aluminum include the following steps:

[0032] (1) Clean the surface of the sample before electrolytic corrosion: rinse the polished sample with alcohol, the sample size is 15mm×19mm×6mm, and dry it with a hair dryer with cold air to ensure that the surface of the sample is free of dust and other pollutants;

[0033] (2) Preparation of electrolytic etchant: the composition of the etchant includes 20ml of hydrogen fluoride solution, 2.8g of boric acid, and 200ml of distilled water with a volume fraction of 40%. Pour distilled water, hydrogen fluoride solution, and boric acid into a clean container successively at room temperature, and stir until the boric acid Dissolve completely, and use after standing at a temperature lower than room temperature (20°C) for 20 minutes;

[0034] (3) Electrolytic corrosion: Turn on the DC power supply, adjust the voltage to 10V, c...

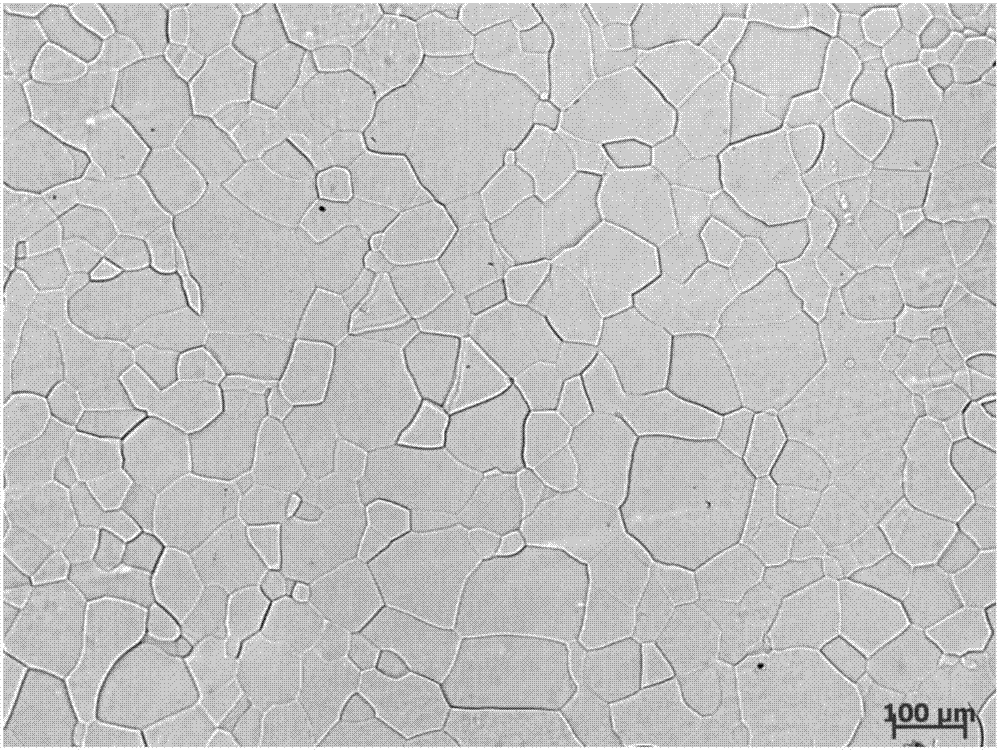

Embodiment 3

[0038] An electrolytic etchant and a corrosion method for displaying the metallographic structure of 6N high-purity aluminum include the following steps:

[0039] (1) Surface cleaning of the sample before electrolytic corrosion: Rinse the polished sample with alcohol, the size of the sample is 15mm×18mm×6mm, and dry it with a hair dryer with cold air to ensure that the surface of the sample is free of dust and other pollutants;

[0040] (2) Preparation of electrolytic etchant: the composition of the etchant includes 23ml of hydrogen fluoride solution, 2.6g of boric acid, and 200ml of distilled water with a volume fraction of 40%. Pour distilled water, hydrogen fluoride solution, and boric acid into a clean container successively at room temperature, and stir until the boric acid Dissolve completely, and use after standing at a temperature lower than room temperature (20°C) for 20 minutes;

[0041] (3) Electrolytic corrosion: Turn on the DC power supply, adjust the voltage to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com