Method for improving interfacial catalysis reaction efficiency based on microcapsule prepared from natural pure protein

A catalytic reaction, protein technology, applied in the direction of enzyme stability, etc., can solve the problems of poor biocompatibility, reduce the stability of natural protein enzymes, etc., to achieve the effect of ensuring stability, good biocompatibility, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

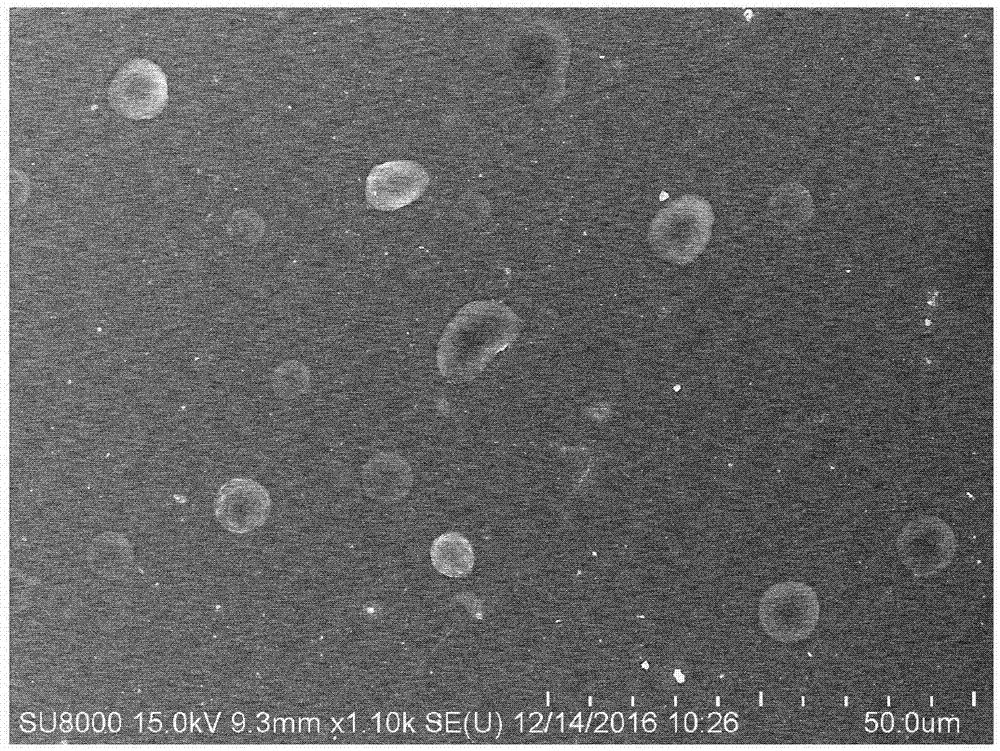

Image

Examples

specific Embodiment approach 1

[0017] Embodiment 1: A method of preparing microcapsules based on natural pure protein in this embodiment to improve the efficiency of interface catalytic reaction is carried out according to the following steps:

[0018] 1. Preparation of PBS buffer solution: NaH 2 PO 4 and Na 2 HPO 4 Mix and dissolve in deionized water to prepare PBS buffer solution; the NaH 2 PO 4 with Na 2 HPO 4 The mass ratio is 1:(25~46); the concentration of the PBS buffer solution is 45mmol / L~55mmol / L, and the pH value is 8.0~8.2;

[0019] 2. Preparation of natural pure protein solution: dissolve natural pure protein in the PBS buffer solution obtained in step 1 to obtain natural pure protein solution; the concentration of the natural pure protein solution is 0.5mg / mL~2mg / mL; The natural pure protein is one or a mixture of several of lysozyme, lipase and urease, and when the natural pure protein is a mixture, various substances are mixed in equal mass;

[0020] Three, the preparation of oil pha...

specific Embodiment approach 2

[0024] Specific embodiment two: the difference between this embodiment and specific embodiment one is: NaH described in step one 2 PO 4 with Na 2 HPO 4 The mass ratio is 1:40. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the concentration of the PBS buffer solution in step 1 is 50 mmol / L. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com