High-temperature plasma gasifying and fusing treatment system and method for industrial wastes

A technology of industrial waste and treatment system, applied in the field of ion gasification melting treatment system, can solve the problems of high maintenance cost and risk, high requirements for anti-seepage treatment, flammability, etc., and solve the problem of secondary pollution from landfill and incineration , broad market application prospects, and low processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

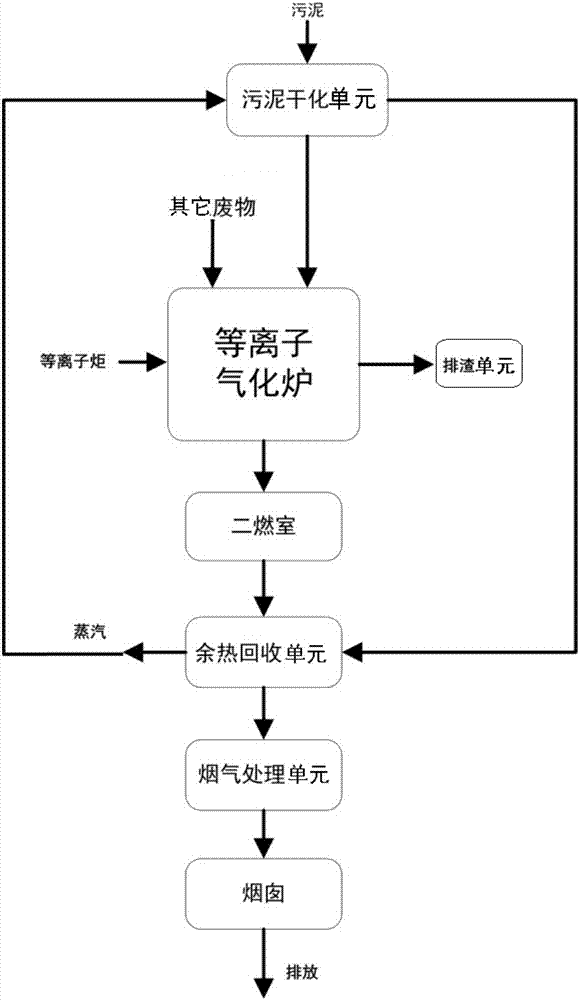

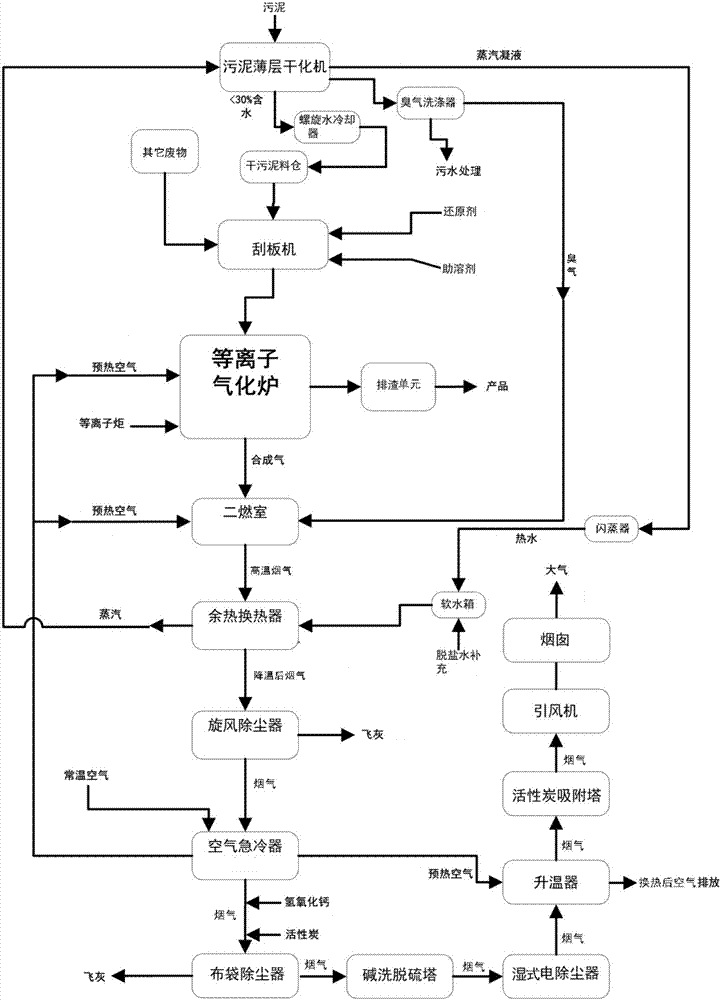

[0023] Such as figure 1 and figure 2 As shown, the high-temperature plasma gasification melting processing system of the present invention includes a plasma gasification unit, a waste heat recovery unit, and a flue gas treatment unit connected in sequence through pipelines, wherein the plasma gasification unit includes a scraper machine, Plasma gasification furnace, secondary combustion chamber and slagging unit, industrial waste enters the plasma gasification furnace through a scraper machine, and the plasma gasification furnace is also equipped with a plasma torch to generate plasma and make the industrial waste in the plasma gas Plasma gasification reaction occurs in the furnace to generate CO, H 2 、CH 4 Wait for the synthesis gas, and then the synthesis gas is reburned in the second combustion chamber to remove the organic components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com