Mixed type soil conditioner and method for preparing same

A soil conditioner and mixed technology, which is applied in the field of mixed soil conditioner and its preparation, can solve the problems of heavy metal pollution remediation and improvement technology is still rare, and the improvement agent progress is slow, so as to improve the soil quality of fertilization soil, The effect of reducing the content of heavy metals and improving the structure of soil aggregates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

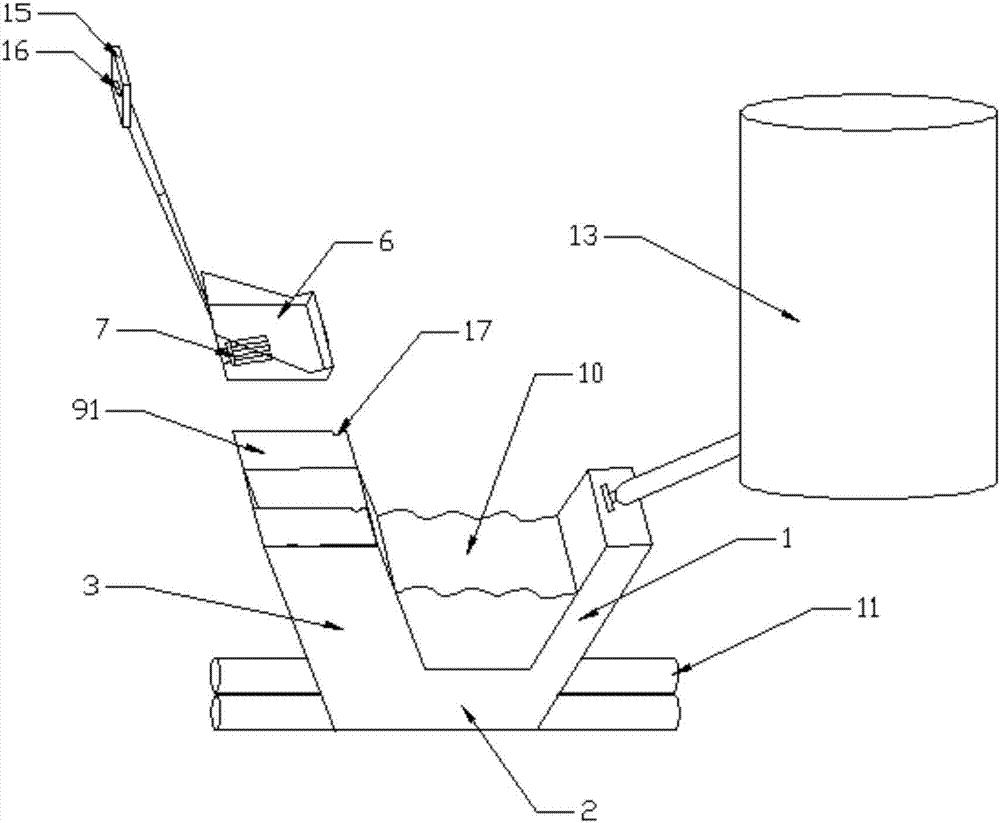

[0029] Such as Figures 1 to 2As shown, a quenching device for quenching calcined shell powder includes a U-shaped treatment box 4 composed of a feed tank 1, a quenching zone 2 and a discharge channel 3, and a hopper 6 with a lifting rod 5. A stirring device 7 is also installed on the side wall of the hopper 6; a feed control valve 8 is provided on the feed tank 1, and a box cover 9 is provided at the upper end of the discharge channel 3; a U-shaped processing box 4 quenching zone 2 A pool 10 is arranged above and a water pipe 11 is arranged below. A connection plate 15 is provided at the end of the lifting rod 5 away from the hopper 6 , and an insertion hole 16 is provided on the connection plate 15 . The stirring device 7 comprises a driving plate 71 and a stirring rod 72 installed on the driving plate 71, the stirring rod 72 is a hollow structure, and the stirring rod 72 is filled with cooling liquid; the case cover 9 is composed of two sub-case covers 91 One end of the s...

Embodiment 2

[0033] A mixed type soil conditioner, comprising 20 parts by weight of cassava residue, 5 parts of rice bran, 0.5 part of selenium powder, 15 parts of shell powder, 25 parts of calcined shell powder, 10 parts of dried sludge, 15 parts of bentonite, 8 parts of sepiolite, 1.5 parts of ferromanganese ore powder. Among them, cassava residue is cassava processing waste peeled by a high-pressure water gun; calcined shell powder is calcined shell powder obtained by grinding at 800° C. for 8 hours, quenched by the above-mentioned quenching device, and then ground. The preparation method of the selenium-enriched high-calcium organic fertilizer comprises the steps of:

[0034] Step a, pretreatment: dehydrate the cassava residue and mix it with dried sludge at a mass ratio of 1.5:1, add rice bran, control the moisture content below 65%, and obtain a pretreatment mixture.

[0035] Step b, trough fermentation: add RW rot accelerator to the mixed material obtained in step a, carry out aero...

Embodiment 3

[0044] Adopt the soil conditioner prepared by embodiment 2 to be applied on the paddy fields of Jinchengjiang District: compared with the contrast, the application of the soil conditioner has effectively improved the yield of paddy rice. Plant height, ear length, number of grains per ear, and number of empty grains were not significantly different. The application of soil conditioner increased the effective number of ears of rice and improved the resistance of rice during the rice growth period. The application of soil conditioner (200 kg / mu) Compared with the control group, the yield of rice was improved by 16.2%.

[0045] Table 2 Effect of soil conditioner on rice yield

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com