Graphene-based waterborne acrylic paint and preparation method thereof

An alkene-based water-based, graphene technology, used in antifouling/underwater coatings, anti-corrosion coatings, coatings, etc., can solve the problems of inability to achieve the excellent performance of graphene, reduce dispersion stability, etc., to achieve enhanced bonding force, distance The effect of shortening and increasing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) drying the monolayer graphene oxide dispersion by atomization drying method to obtain graphene oxide microspheres, the atomization temperature is 130°C;

[0026] (2) placing the graphene oxide microspheres obtained in step (1) in hydrazine hydrate vapor, and reducing them for 1 hour at 60° C. to obtain reduced graphene oxide microspheres;

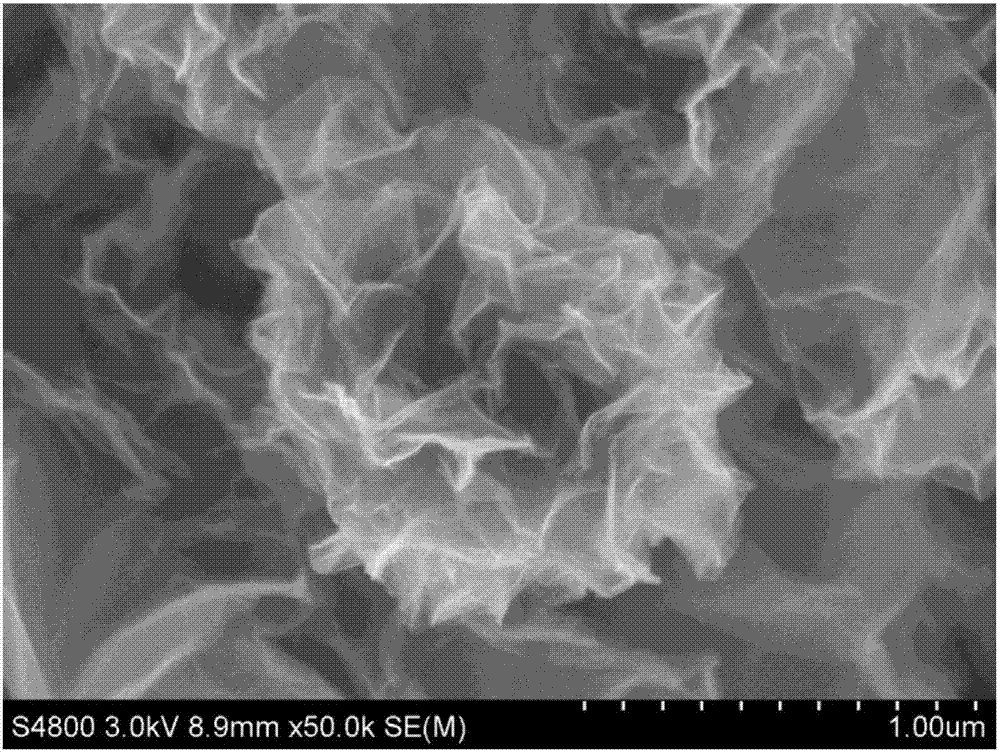

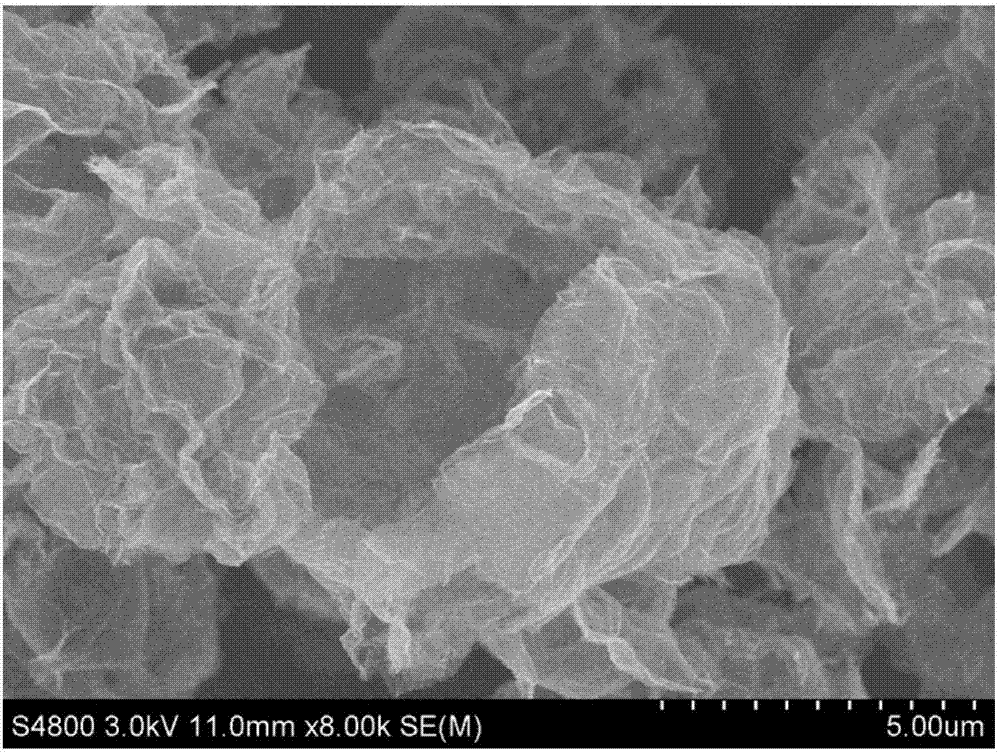

[0027] (3) Putting the reduced graphene oxide microspheres obtained in step (2) into a tube furnace, continuously feeding nitrogen, and raising the temperature to 1000° C., and keeping it warm for 1 hour to obtain paper ball-shaped graphene microspheres;

[0028] (4) Stir 0.3 parts of the paper ball shape graphene microspheres obtained in step (3) with 100 parts of pure acrylic emulsion, and ultrasonically disperse, then add 15 parts of water, 0.3 parts of dispersant, 0.1 part of preservative, 0.3 1 part of film former, 0.1 part of leveling agent, 4 parts of thickener, 0.3 part of defoamer, 10 parts of calcium carbonate, 10 parts...

Embodiment 2

[0031] (1) drying the monolayer graphene oxide dispersion by atomization drying method to obtain graphene oxide microspheres, the atomization temperature is 130°C;

[0032](2) placing the graphene oxide microspheres obtained in step (1) in hydrazine hydrate vapor, and reducing them for 1 hour at 90° C. to obtain reduced graphene oxide microspheres;

[0033] (3) Putting the reduced graphene oxide microspheres obtained in step (2) into a tube furnace, continuously feeding nitrogen, and raising the temperature to 1000° C., and keeping it warm for 1 hour to obtain paper ball-shaped graphene microspheres;

[0034] (4) Stir 0.3 parts of the paper ball shape graphene microspheres obtained in step (3) with 100 parts of pure acrylic emulsion, and ultrasonically disperse, then add 15 parts of water, 0.3 parts of dispersant, 0.1 part of preservative, 0.3 1 part of film former, 0.1 part of leveling agent, 4 parts of thickener, 0.3 part of defoamer, 10 parts of calcium carbonate, 10 parts ...

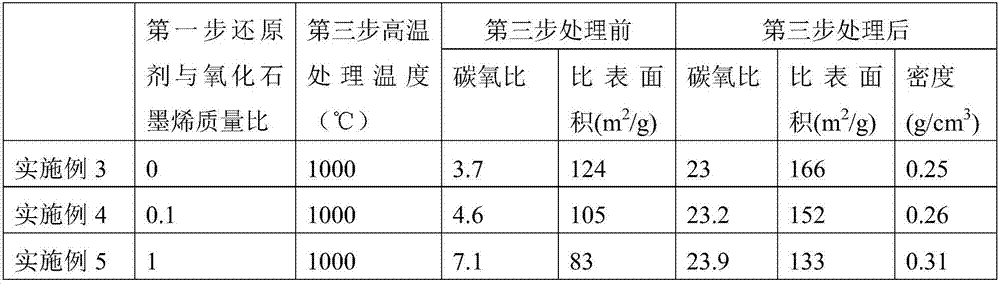

Embodiment 3

[0037] (1) drying the monolayer graphene oxide dispersion by atomization drying method to obtain graphene oxide microspheres, the atomization temperature is 130°C;

[0038] (2) placing the graphene oxide microspheres obtained in step (1) in hydrazine hydrate vapor, and reducing them for 24 hours at 90° C. to obtain reduced graphene oxide microspheres;

[0039] (3) Putting the reduced graphene oxide microspheres obtained in step (2) into a tube furnace, continuously feeding nitrogen, and raising the temperature to 1000° C., and keeping it warm for 1 hour to obtain paper ball-shaped graphene microspheres;

[0040] (4) Stir 0.3 parts of the paper ball shape graphene microspheres obtained in step (3) with 100 parts of pure acrylic emulsion, and ultrasonically disperse, then add 15 parts of water, 0.3 parts of dispersant, 0.1 part of preservative, 0.3 1 part of film former, 0.1 part of leveling agent, 4 parts of thickener, 0.3 part of defoamer, 10 parts of calcium carbonate, 10 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com