Trifluoromethanesulfonic acid metal salt/benzoxazine resin composition and preparation method thereof

A trifluoromethanesulfonic acid and resin composition technology, applied in the field of trifluoromethanesulfonic acid metal salt/benzoxazine resin composition and its preparation, can solve the problems of loss of material performance, high curing temperature, high brittleness, etc. , to achieve the effect of improving heat resistance, reducing the curing peak temperature greatly, and adding less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

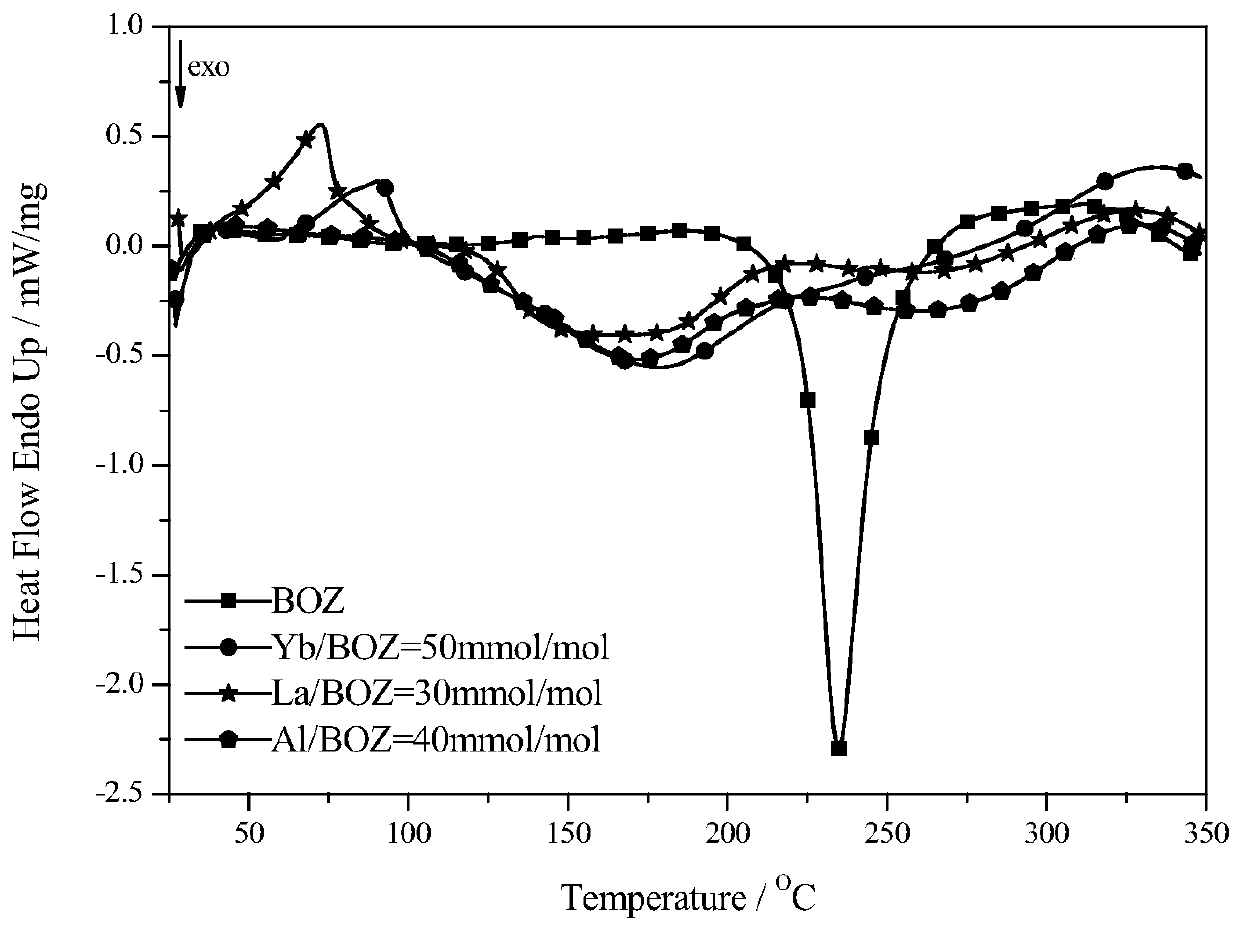

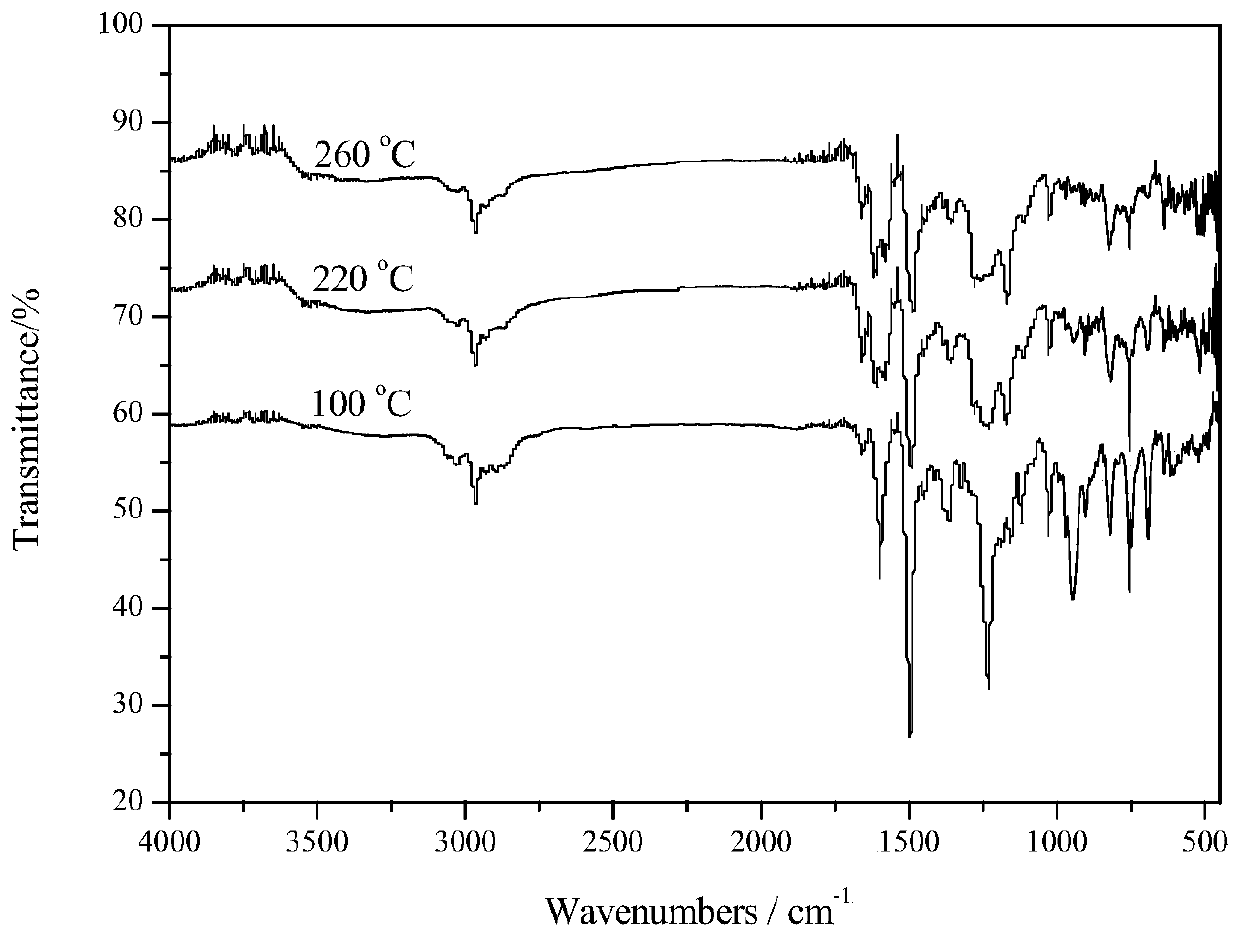

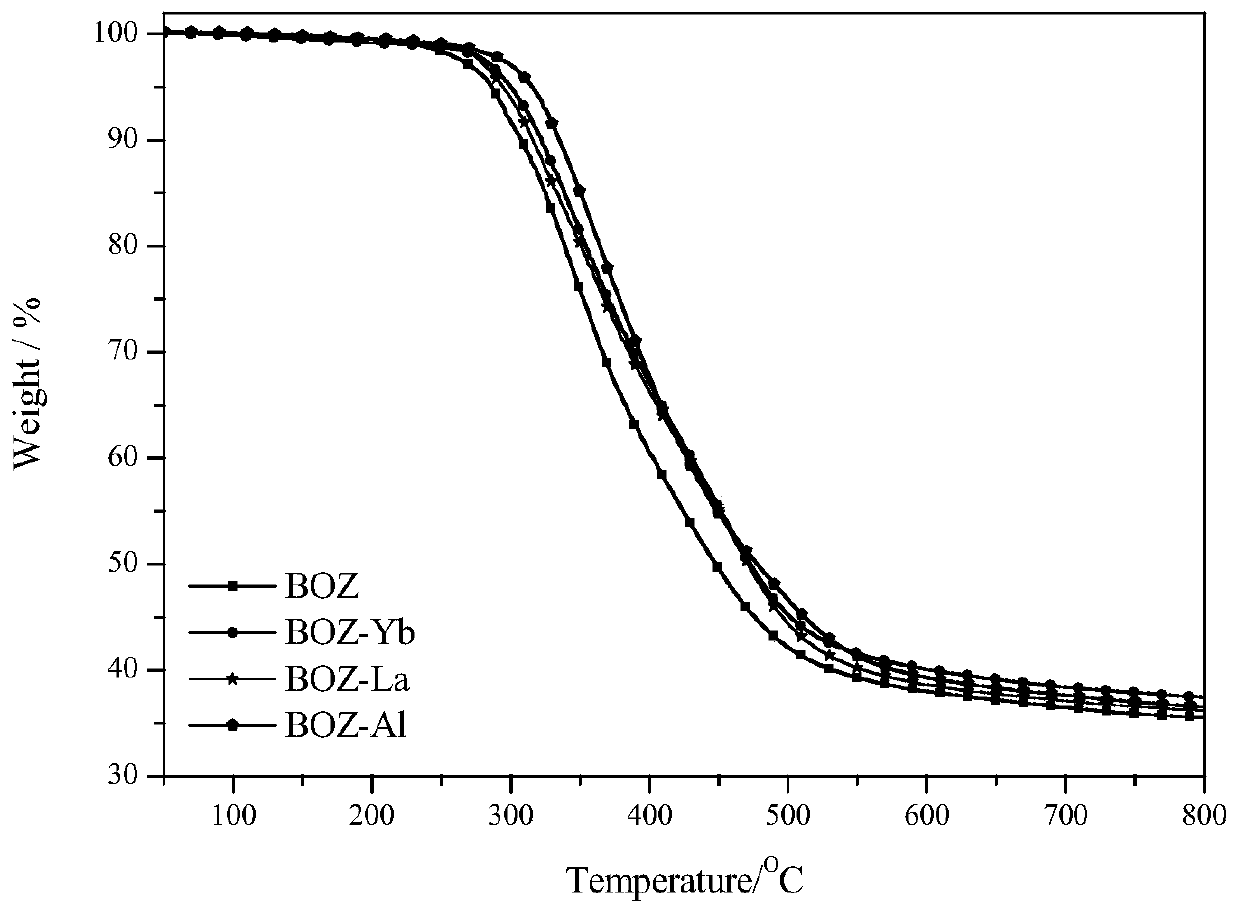

[0026] Embodiment 1 Based on aluminum trifluoromethanesulfonate catalyzed as catalyst curing benzoxazine resin method

[0027] Aluminum trifluoromethanesulfonate and benzoxazine resin are mixed in a ratio of 40mmol / mol (the mass percentage content of aluminum trifluoromethanesulfonate is 3.96wt%), it is dissolved in toluene solvent, trifluoromethanesulfonic acid The mass percent concentration of aluminum and benzoxazine resin in the mixed solution is adjusted to be 50wt%. Stir at room temperature until completely dissolved, then dry in a vacuum oven at 80°C to constant weight, and grind the mixture in a mortar to make it evenly mixed. The homogeneously mixed samples were transferred to molds. Put the mold into a forced air drying oven, and use a stepwise heating program (120°C / 1h, 150°C / 1h, 180°C / 2h, 210°C / 1h) to cure to obtain benzoxazine resin (BOZ-Al).

Embodiment 2

[0028] Embodiment 2 is based on ytterbium trifluoromethanesulfonate and catalyzes the method for curing benzoxazine resins as a catalyst

[0029] Mix ytterbium trifluoromethanesulfonate and benzoxazine resin in a ratio of 50mmol / mol (the mass percent content of ytterbium trifluoromethanesulfonate is 6.31wt%), dissolve it in chloroform solvent, trifluoromethanesulfonic acid The mass percent concentration of aluminum and benzoxazine resin in the mixed solution is adjusted to be 60wt%. Stir at room temperature until completely dissolved, then dry in a vacuum oven at 50°C to constant weight, and grind the mixture in a mortar to make it evenly mixed. The homogeneously mixed samples were transferred to molds. Put the mold into a forced air drying oven, and use a stepwise temperature rise program (120°C / 1h, 150°C / 1h, 180°C / 2h, 210°C / 1h) to cure to obtain benzoxazine resin (BOZ-Yb).

Embodiment 3

[0030] Embodiment 3 is based on lanthanum trifluoromethanesulfonate and catalyzes the method for curing benzoxazine resin as a catalyst

[0031] Lanthanum trifluoromethanesulfonate is mixed with benzoxazine resin in a ratio of 30mmol / mol (the mass percentage content of lanthanum trifluoromethanesulfonate is 3.68wt%), it is dissolved in dioxane solvent, trifluoromethanesulfonate The mass percent concentration of aluminum methanesulfonate and benzoxazine resin in the mixed solution is adjusted to be 40wt%. Stir at room temperature until completely dissolved, then dry in a vacuum oven at 70°C to constant weight, and grind the mixture in a mortar to make it evenly mixed. The homogeneously mixed samples were transferred to molds. Put the mold into a forced air drying oven, and use a stepwise heating program (120°C / 1h, 150°C / 1h, 180°C / 2h, 210°C / 1h) to cure to obtain benzoxazine resin (BOZ-La).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com