Treatment system for removing COD and ammonia nitrogen in steam

A treatment system and steam technology, which is applied in the field of COD and ammonia nitrogen removal treatment systems in steam, can solve the problems of large processing capacity, low energy consumption, and small footprint, and achieve the effects of reduced corrosion, uniform distribution, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

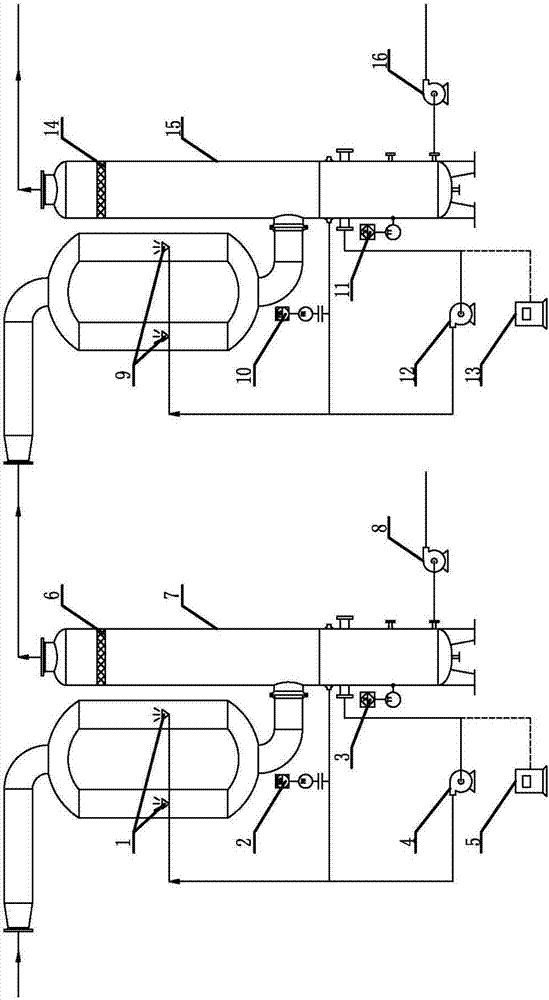

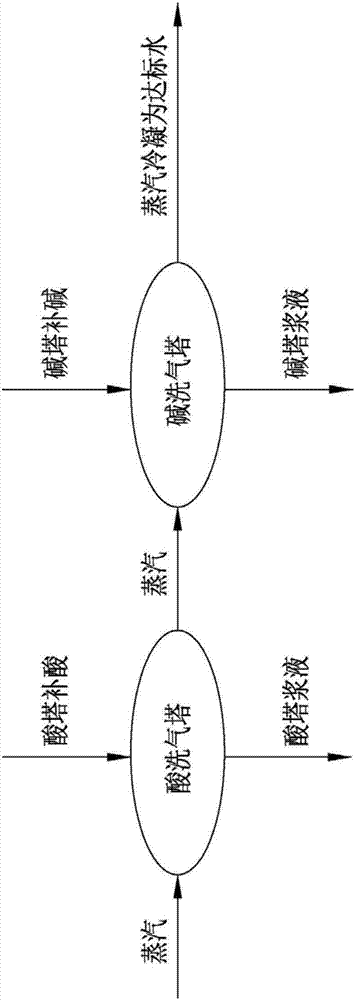

[0040] This embodiment discloses a treatment system for removing COD and ammonia nitrogen in steam, its structure is as follows figure 1 , figure 2 Shown, including acid scrubbing system and alkali scrubbing system. The evaporation temperature of the acid scrubbing system and the alkali scrubbing system is 60°C-115°C.

[0041] The pickling gas system includes a pickling gas tower 7, an acid spray system 1, an acid tower circulation pump 4 connected to the liquid outlet at the lower end of the pickling gas tower 7 and the spray head of the acid spray system 1, and connected to the acid spray system 1 With the first pH system 2 of the pickling gas tower 7, the automatic acid supply system 5 arranged on the pipeline between the acid tower circulation pump 4 and the pickling gas tower 7, the outlet of the acid spray system 1 bottom is connected with the pickling gas Tower 7 inlet is communicated, and described pickling gas tower 7 upper end is provided with the acid eliminator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com