Process for purifying byproduct sodium sulfate from pyraclostrobin

A by-product technology of sodium sulfate and pyraclostrobin, which is applied in the fields of alkali metal sulfite/sulfate purification, heating water/sewage treatment, etc., can solve the problem of damaging the economy, destroying the production equipment of the company's sewage treatment plant, and unfavorable Production and processing issues, to achieve the effect of ensuring personal safety and property safety, reflecting economy and practicability, and optimizing purification process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

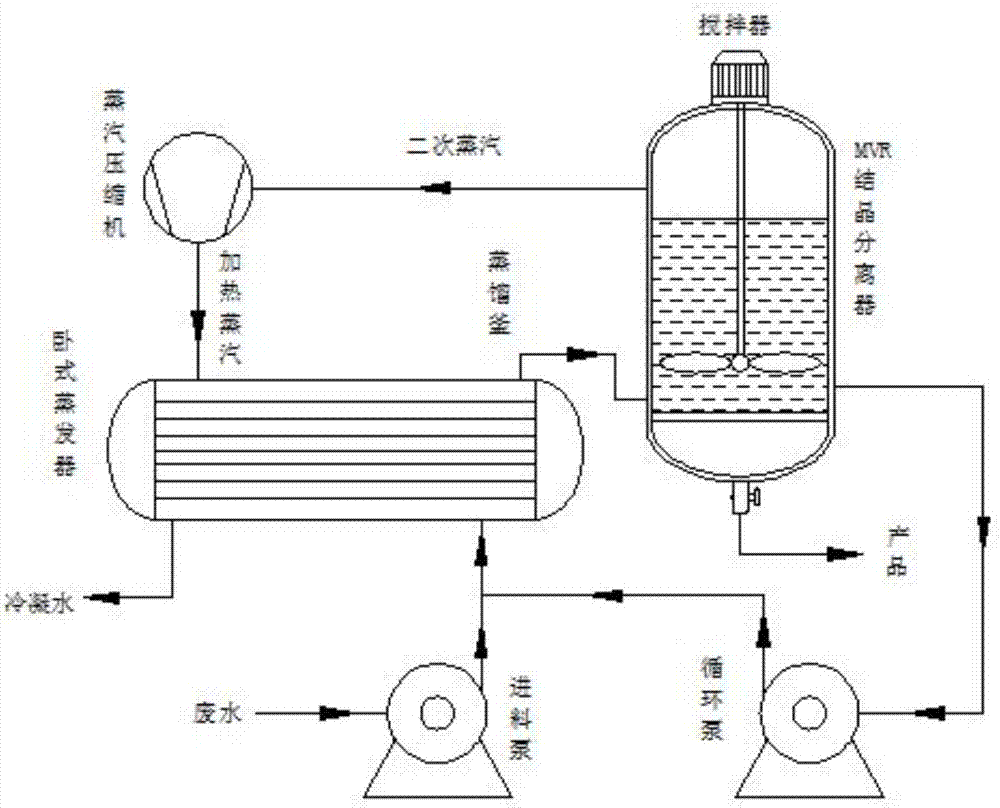

[0024] see figure 1 As shown, the technical scheme adopted in the present invention is: a kind of purification process of pyraclostrobin by-product sodium sulfate, and the specific steps of the purification process of pyraclostrobin by-product sodium sulfate are:

[0025] (1). Evaporation and crystallization: the waste water produced by the synthesis of p-chlorophenylhydrazine contains sodium sulfate, and the waste water containing sodium sulfate is transported by the feed pump to the horizontal evaporator for heat exchange with heating steam. After heat exchange with heating steam Enter the MVR crystal separator, continuously stir for 1-2 hours, the waste water entering the MVR crystal separator evaporates to produce secondary steam and sodium sulfate concentrate;

[0026] (2).Wastewater treatment: The secondary steam generated during the evaporation process in the MVR crystallizer flows through the steam compressor for vapor compression treatment, from low temperature and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com