A kind of pasture grinder with three crushing chambers

A crushing chamber and crushing machine technology, applied in agricultural machinery and tools, agriculture, grain processing, etc., can solve the problems of being unable to crush, difficult to crush, and difficult to achieve knife alignment, etc., to achieve convenient and simple installation, avoid clogging the screen, and improve The effect of crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

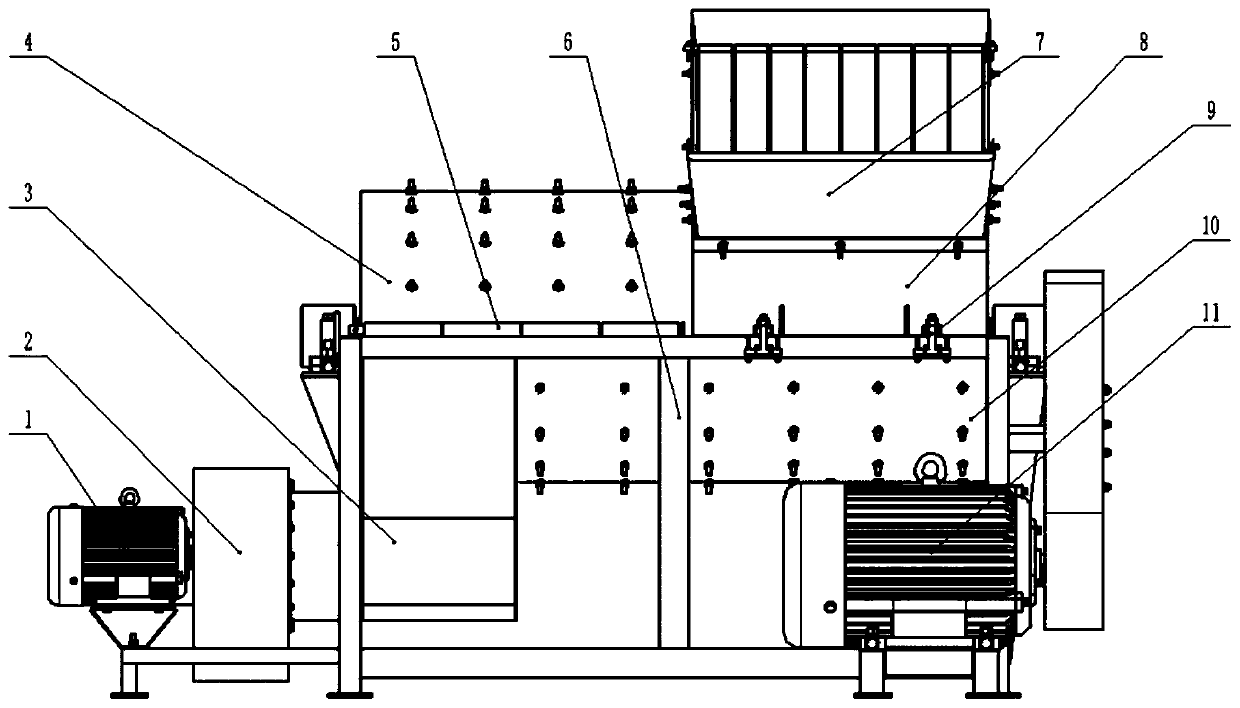

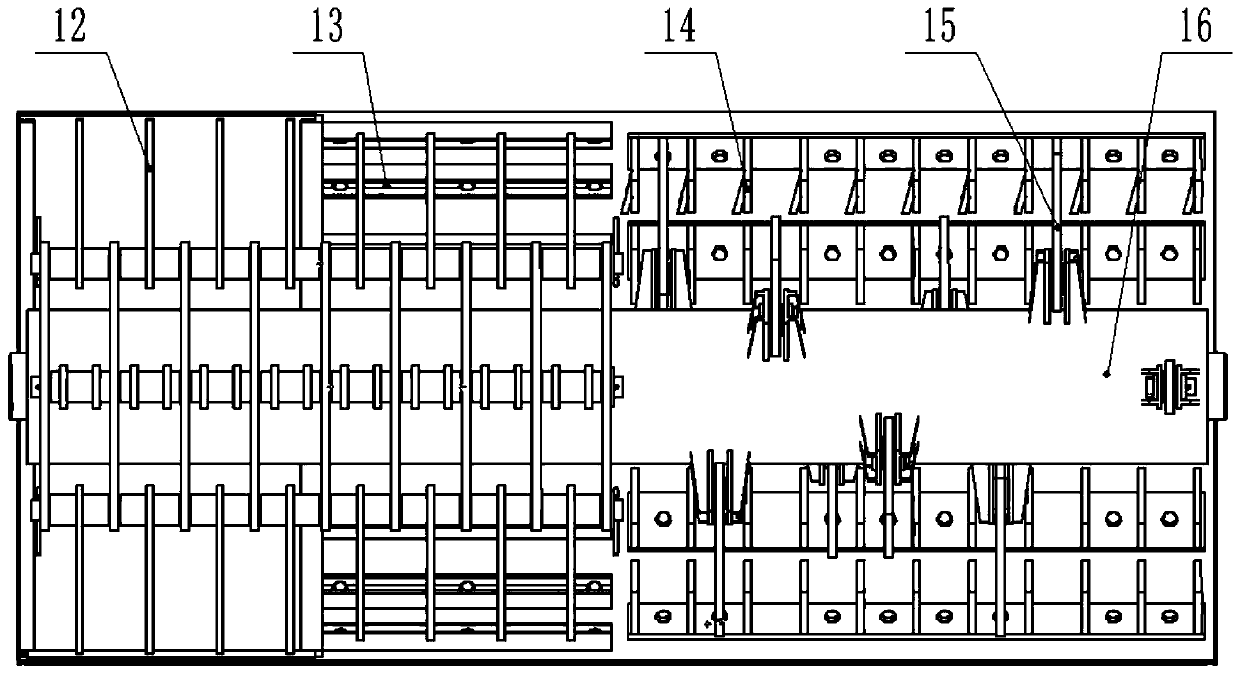

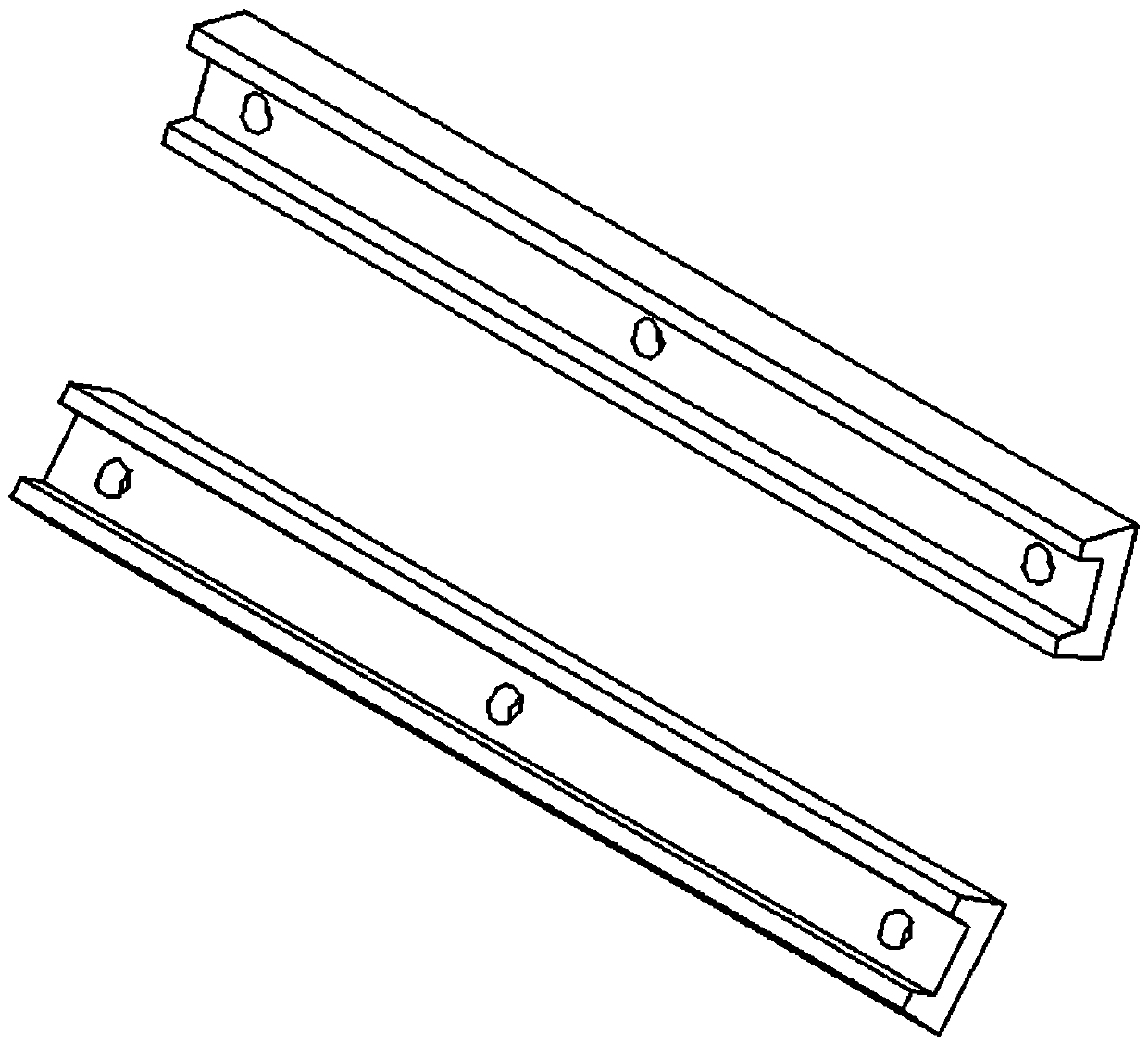

[0030] Such as Figure 1-Figure 2 Shown is a three-chamber forage grinder provided by the present invention, which includes a frame 6, a housing, a main shaft 16, a fixed knife 15, a moving knife 16, a concave tooth plate 13 and a fan 2.

[0031] The upper left cover 4 and the upper right cover 8 are connected to form an upper casing, and the upper left cover 4 and the upper right cover 8 are sealed by rubber; the upper casing and the lower casing 10 form a casing. The lower casing 10 is fixed on the frame 6 by welding. The upper left cover 4 and the upper right cover 8 are respectively connected to the lower housing 10 through hinges 5 and fixed through a bolt locking mechanism 9 . Loosen the bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com