Acid solution and hydrogen recycling method and equipment thereof

A technology for recovering equipment and hydrogen, which is applied in the direction of using liquid contact hydrogen separation, hydrogen separation, and vapor condensation, etc., can solve the problems of high cost, waste of resources, complicated processes, etc., and achieves low management costs, avoidance of resource waste, and simple maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

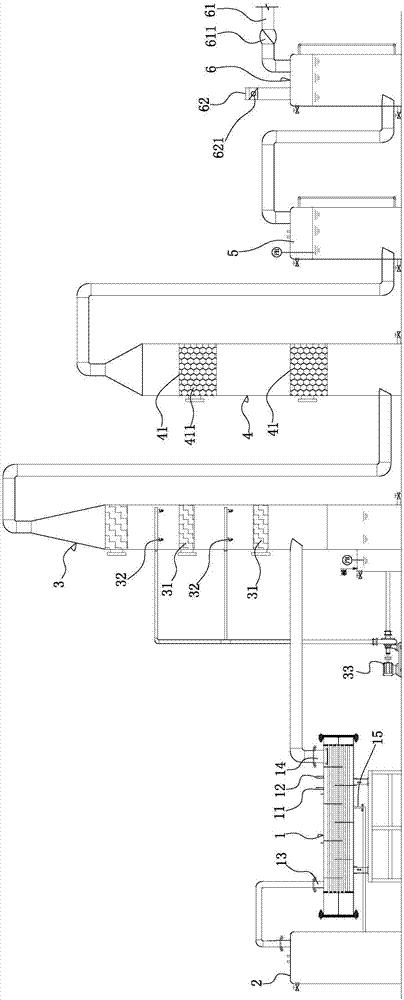

[0024] see figure 1 As shown, it is an acid liquid reuse and hydrogen recovery equipment, which includes a reaction kettle 2, a condenser 1, a neutralization tower 3, a demister tower 4, a constant pressure water seal 5 and a safety water seal 6 connected in sequence.

[0025] The condenser 1 is a tube-and-tube condenser, and the condenser 1 is connected to the reactor 2 to cool the gas containing hydrogen, sulfuric acid, phosphoric acid, and water vapor discharged from the reactor, so that most of the water in the gas Steam and acid mist are condensed from gas to liquid, and the condensed liquid is returned to the reactor for continued use, and the condensed liquid is returned to the reactor for continued use, avoiding the waste of acid liquid. The condenser 1 has a cold water inlet 11 and a cold water outlet 12, the cold water inlet 11 communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com