Deep ultraviolet LED epitaxial structure and fabrication method thereof

An epitaxial structure and deep ultraviolet technology, which is applied in the field of ultraviolet LEDs, can solve the difficulties in the production of high-quality P-type AlGaN, restrict the development of AlGaN deep ultraviolet LEDs, etc., achieve high luminous efficiency and ensure the effect of crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

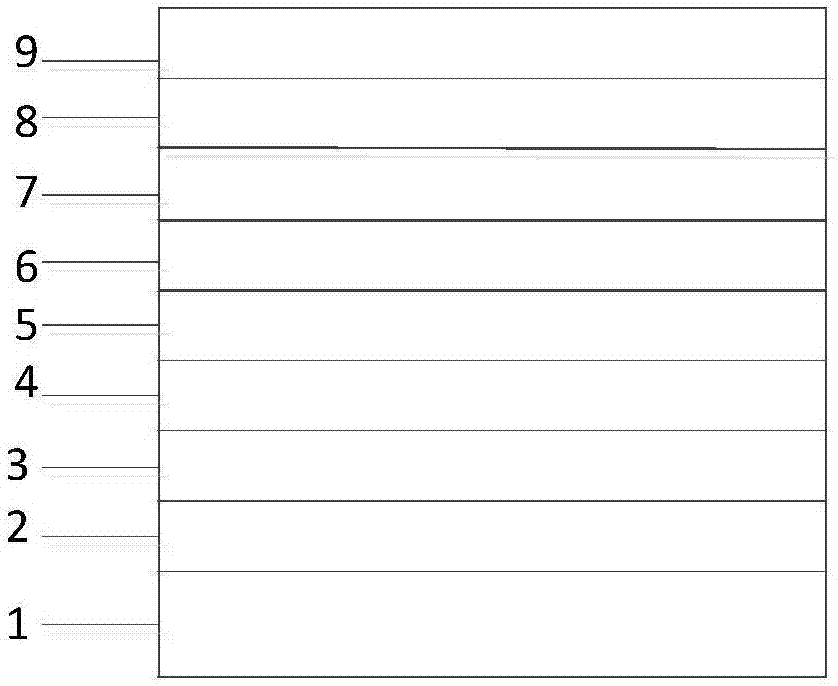

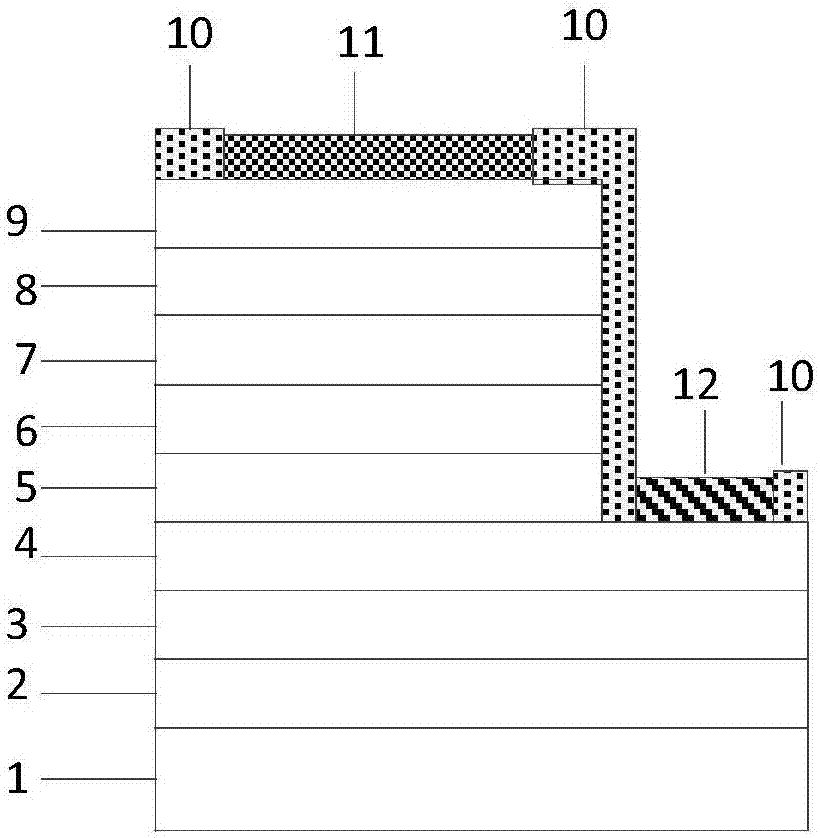

[0022] Such as figure 1 As shown, the epitaxial structure of the present invention is sequentially grown on the substrate material based on MOCVD, specifically:

[0023] The nucleation layer 2 is grown on a transparent substrate with a growth temperature of 950° C. and a growth pressure of 50 mbar; the nucleation layer 2 is made of GaN, AlN or AlGaN with a thickness of 10 nm-50 nm, and the thickness of this embodiment is 15 nm.

[0024] The substrate can be sapphire, AlN, GaN, etc.

[0025]The buffer layer 3 is grown on the nucleation layer, the growth temperature is 1200°C, and the growth pressure is 100mbar; the buffer layer 3 is unintentionally doped u-type AlGaN, the Al composition is 0.2-0.6, and the thickness is 1um-5um. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com