Method of preventing vortex slag entrapment through argon blowing in steel ladle tapping process

A technology of tapping process and ladle, applied in the direction of casting melt containers, manufacturing tools, metal processing equipment, etc., can solve the problems of disturbing the flow field distribution caused by the vortex, and achieve the advantages of homogenization, low cost and high yield rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

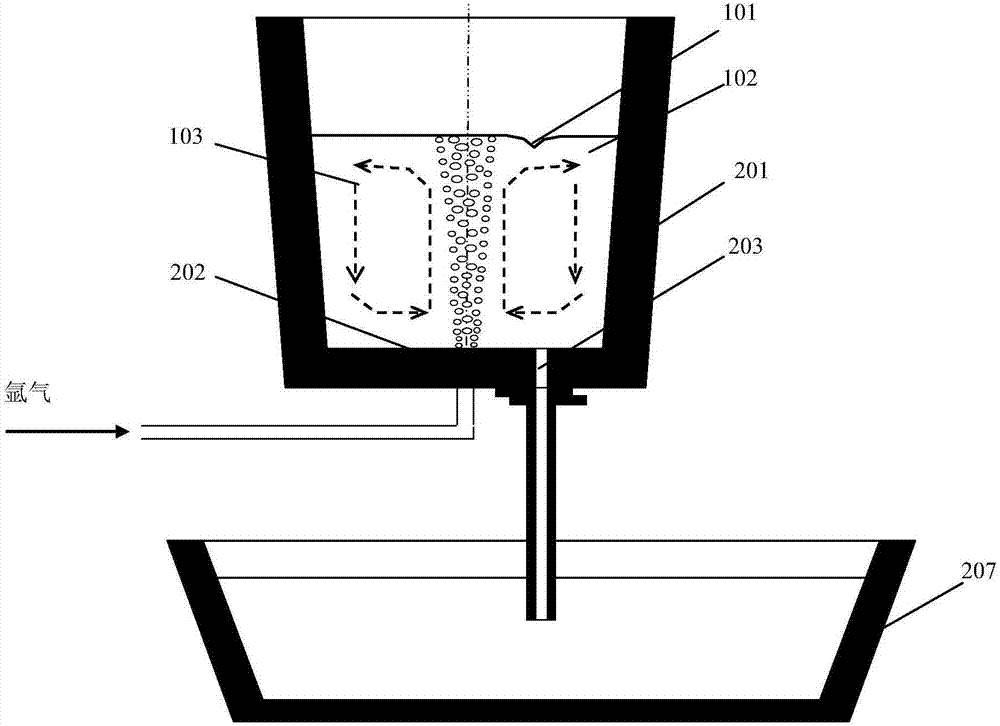

[0024] Using the water model experimental device, in the process of tapping through image 3 No. 1 gas blowing hole 202 in the middle respectively blows gas with a flow rate of 0-1.3 L / min. When the blowing flow rate is 0L / min, that is, the critical height of the vortex is as high as 9.4cm when there is no blowing during the tapping process. After the gas is introduced, the critical height of the vortex decreases significantly with the increase of the blowing flow rate. When the blowing air flow rate is 0.04L / min, the critical height of the vortex drops to 5.5cm; when the air blowing flow rate is 1.3L / min, the critical height of the vortex drops to a minimum of 1.8cm. Therefore, it can be calculated that the final liquid yield obtained in the water model experiment carried out according to the present invention can be increased by about 13%.

[0025] According to the above experimental results, according to the conversion formula Q between the simulated gas and the actual blo...

Embodiment 2

[0028] Using the described water model experimental device, in the process of tapping, through image 3 Middle No. 1-No. 8 blowing hole 202 is blown into the gas that flow rate is 0.06L / min, obtains as follows Figure 5 the experimental results. Depend on Figure 5 It can be seen that the critical height of the vortex is very high when there is no air blowing in the tapping process, but when blowing air through No. 1-8 air blowing holes 202, the critical height of the vortex is significantly reduced. Therefore, in practice, the ladle 201 can be used to refine The air blowing hole 202 used can obtain an obvious swirl suppression effect. In contrast, the effect of suppressing the vortex is the best when blowing air through the No. 7 blowing hole 202 , that is, the position of the blowing hole 202 is close to the center of the ladle 201 , and the effect of suppressing the vortex is relatively good. At the same time, blow air at the best blowing hole 202 position. When the blow...

Embodiment 3

[0031] Using the numerical simulation method, simulated in the tapping process through the Image 6 The specific setting of the slag entrainment after blowing with different air blowing holes in is as follows: without blowing, the blowing flow rate is 0L / min; for single hole blowing, the position of the blowing hole is No. 1 blowing hole, and the blowing flow rate is 100L / min , double-hole blowing, the blowing holes are located at No. 1 and No. 2 blowing holes, and the total blowing flow rate is 100L / min (the single-hole flow rate is 50L / min); double-hole blowing, the positions of the blowing holes are No. 1 and No. 3 , the total blowing flow rate is 100L / min (single hole flow rate is 50L / min). The distance between each blowing hole and the nozzle is R / 4 (R is the radius of the bottom of the ladle). Figure 7 It can be found from the simulation results that whether it is single-hole air blowing or double-hole air blowing, the critical height of the vortex can be significantly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com