Super-soft TPU membrane for U-shaped pillow and preparation method of super-soft TPU membrane

A film and raw material technology, applied in the field of ultra-soft TPU film for U-shaped pillows and its preparation, can solve the problems of further improvement in waterproof and moisture permeability, achieve good breathability and moisture permeability, enhance softness and breathability and moisture permeability, The effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

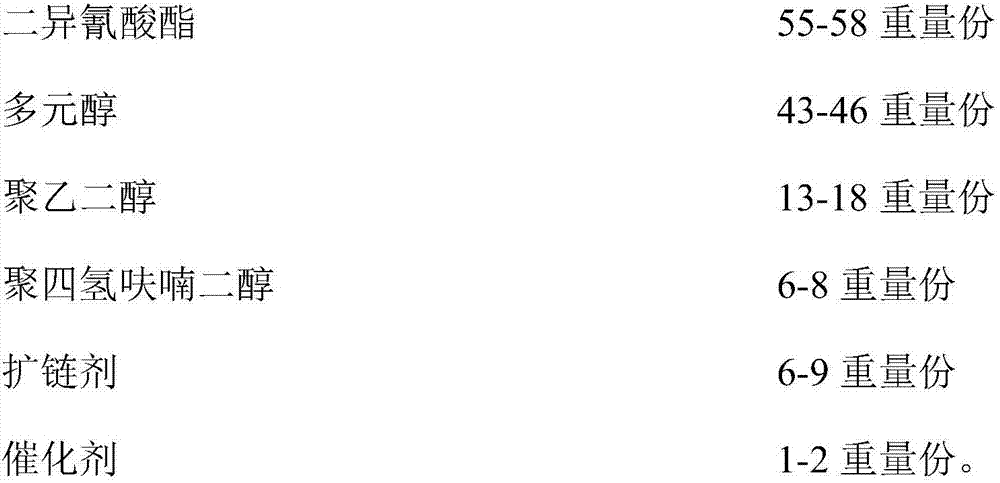

[0043] In this embodiment, the TPU film is prepared from the following raw material components:

[0044]

[0045]Wherein the diisocyanate is a mixture of cyclohexane dimethylene diisocyanate and 1,6-hexamethylene diisocyanate, and the mass ratio of cyclohexane dimethylene diisocyanate and 1,6-hexamethylene diisocyanate is 1:5, so Described polyol is the mixture of polyether polyol and polyester polyol, and the mass ratio of polyether polyol and polyester polyol is 3:1, and the number average molecular weight of described polyol is 1500, and chain extender is ethylene glycol, The catalyst is stannous octoate.

[0046] The preparation method is as follows:

[0047] (1) Add diisocyanate, polyol, chain extender and catalyst into the storage tank, and vacuum dehydrate at 60°C under the pressure of -0.3kPa under the stirring speed of 500r / min;

[0048] (2) Use a vacuum pump to pump and inject each raw material in step (1) into a twin-screw extruder for reaction and granulation....

Embodiment 2

[0051] In this embodiment, the TPU film is prepared from the following raw material components:

[0052]

[0053] Wherein the diisocyanate is a mixture of cyclohexane dimethylene diisocyanate and 1,6-hexamethylene diisocyanate, and the mass ratio of cyclohexane dimethylene diisocyanate and 1,6-hexamethylene diisocyanate is 1:6, so Described polyol is the mixture of polyether polyol and polyester polyol, and the mass ratio of polyether polyol and polyester polyol is 4:1, and the number average molecular weight of described polyol is 2000, and chain extender is ethylene glycol, The catalyst is stannous octoate.

[0054] The preparation method is as follows:

[0055] (1) Add diisocyanate, polyol, chain extender and catalyst into the storage tank, and vacuum dehydrate at 60°C under the pressure of -0.1kPa under the stirring speed of 1000r / min;

[0056] (2) Use a vacuum pump to pump and inject each raw material in step (1) into a twin-screw extruder for reaction and granulatio...

Embodiment 3

[0059] In this embodiment, the TPU film is prepared from the following raw material components:

[0060]

[0061]

[0062] Wherein the diisocyanate is a mixture of cyclohexane dimethylene diisocyanate and 1,6-hexamethylene diisocyanate, and the mass ratio of cyclohexane dimethylene diisocyanate and 1,6-hexamethylene diisocyanate is 1:4, so Described polyol is the mixture of polyether polyol and polyester polyol, the mass ratio of polyether polyol and polyester polyol is 2:1, and the number average molecular weight of described polyol is 2500, and chain extender is 1,3- Propylene glycol, the catalyst is dibutyltin dilaurate.

[0063] The preparation method is as follows:

[0064] (1) Add diisocyanate, polyol, chain extender and catalyst into the storage tank, and vacuum dehydrate at 70°C under the pressure of -0.2kPa under the stirring speed of 800r / min;

[0065] (2) Use a vacuum pump to pump and inject each raw material in step (1) into a twin-screw extruder for reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com