A kind of liquid trans polycyclopentene rubber and its preparation method and application

A technology of polycyclopentene rubber and polycyclopentene, which is applied in the field of rubber and can solve the problems of no literature reports on the synthesis and application of liquid trans polycyclopentene rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

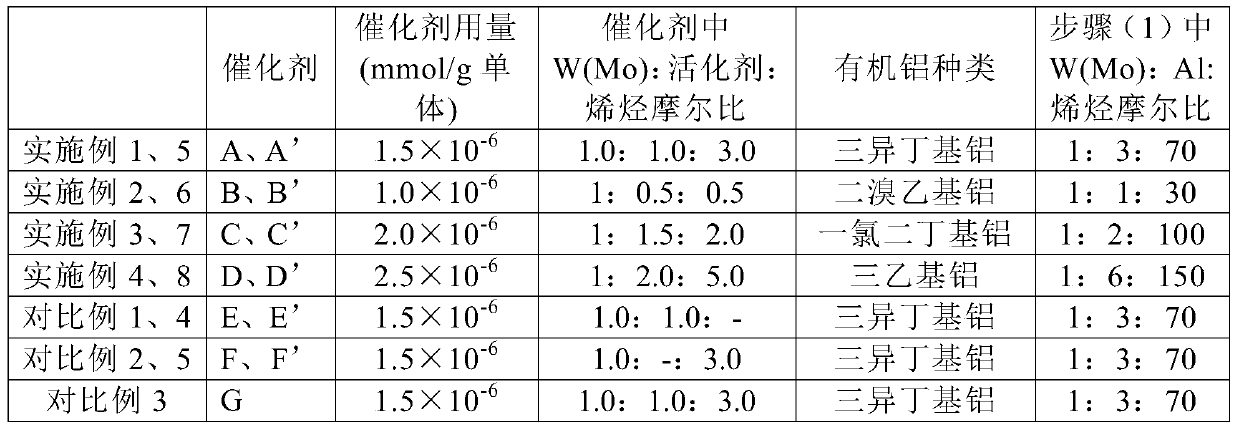

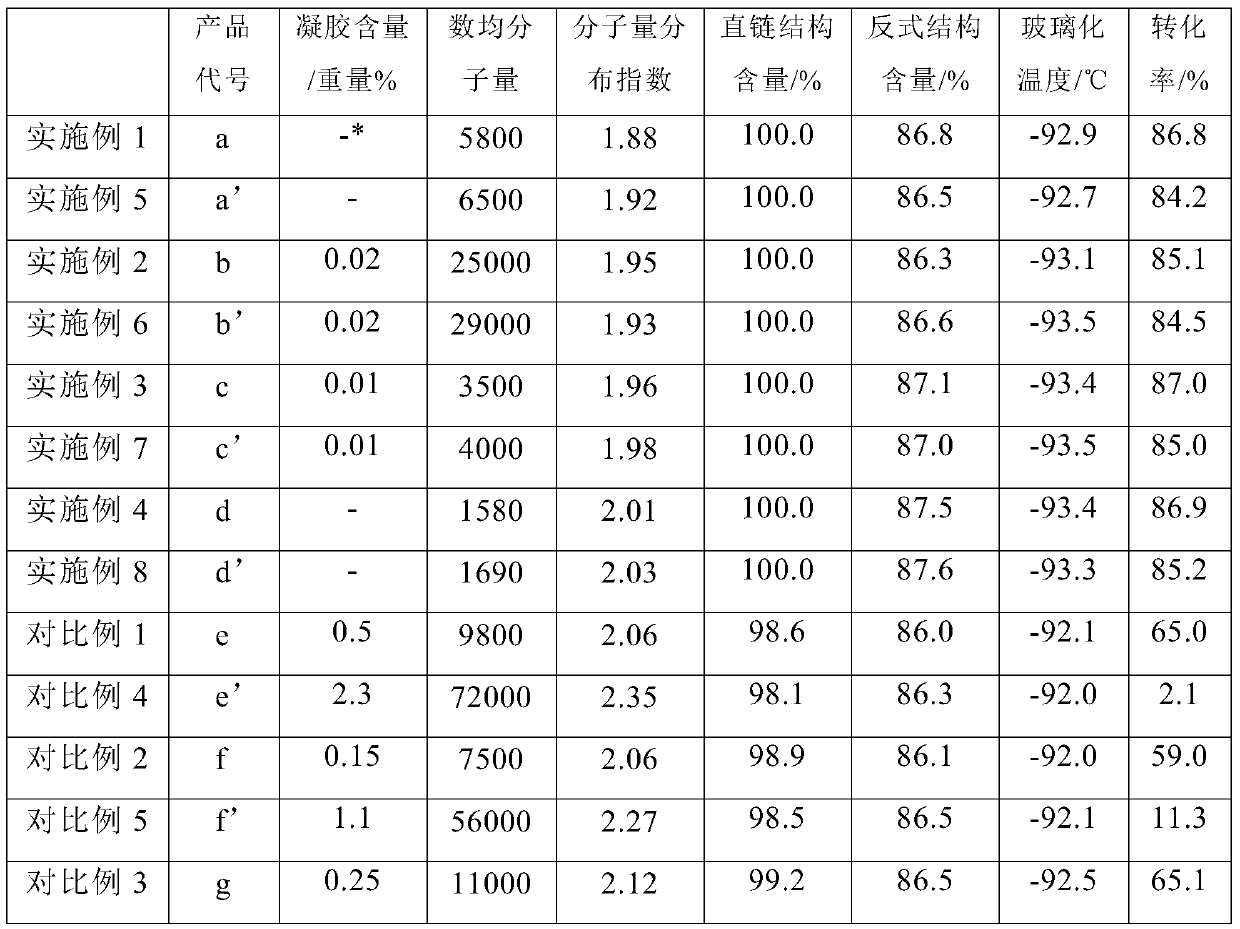

[0053] Fully replace the reaction system with high-purity nitrogen, and add 0.03M WOCl to it 4 100mL of toluene solution, then add 60mL of 0.05M tetrachlorophenol toluene solution and 20mL of 0.45M 1-butene toluene solution under stirring, keep the system temperature at 20°C, and age the resulting mixture at a stirring speed of 200r / min After 30 minutes, the color of the solution was observed to change from dark blue to purple, and catalyst solution A was obtained.

[0054] It is calculated that the molar ratio of the main catalyst component, the oxygen- or halogen-containing activator and the linear monoolefin in the catalyst solution is 1.0:1.0:3.0. .

preparation example 2

[0056] Fully replace the reaction system with high-purity nitrogen, and add 0.05M WCl to it 6 100mL of toluene solution of benzoyl peroxide, and then add 83.3mL of 0.03M benzoyl peroxide toluene solution and 50mL of 0.05M 1-hexene xylene solution under stirring. Aged for 60 minutes at a constant stirring speed, observed that the color of the solution changed from dark blue to purple, and obtained catalyst solution B.

[0057]It is calculated that the molar ratio of main catalyst component, oxygen or halogen-containing activator and linear monoolefin in the catalyst solution is 1:0.5:0.5.

preparation example 3

[0059] Fully replace the reaction system with high-purity nitrogen, and add 0.04M MoBr to it 5 100mL of toluene solution of 1-octene, and then add 120mL of 0.05M epichlorohydrin toluene solution and 2mL of 4.0M 1-octene benzene solution under stirring. Aged for 20 minutes to obtain catalyst solution C.

[0060] It is calculated that the molar ratio of main catalyst component, oxygen or halogen-containing activator and linear monoolefin in the catalyst solution is 1:1.5:2.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com