A dust collection device for electric tools

A technology for vacuuming devices and power tools, which is applied in the directions of combination devices, cleaning methods and utensils, removing smoke and dust, etc., can solve the problems of polluted air, increase the amount of dust in the surrounding air, complex structure, etc., and achieve good flame retardancy, good Elasticity and water resistance, dust-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

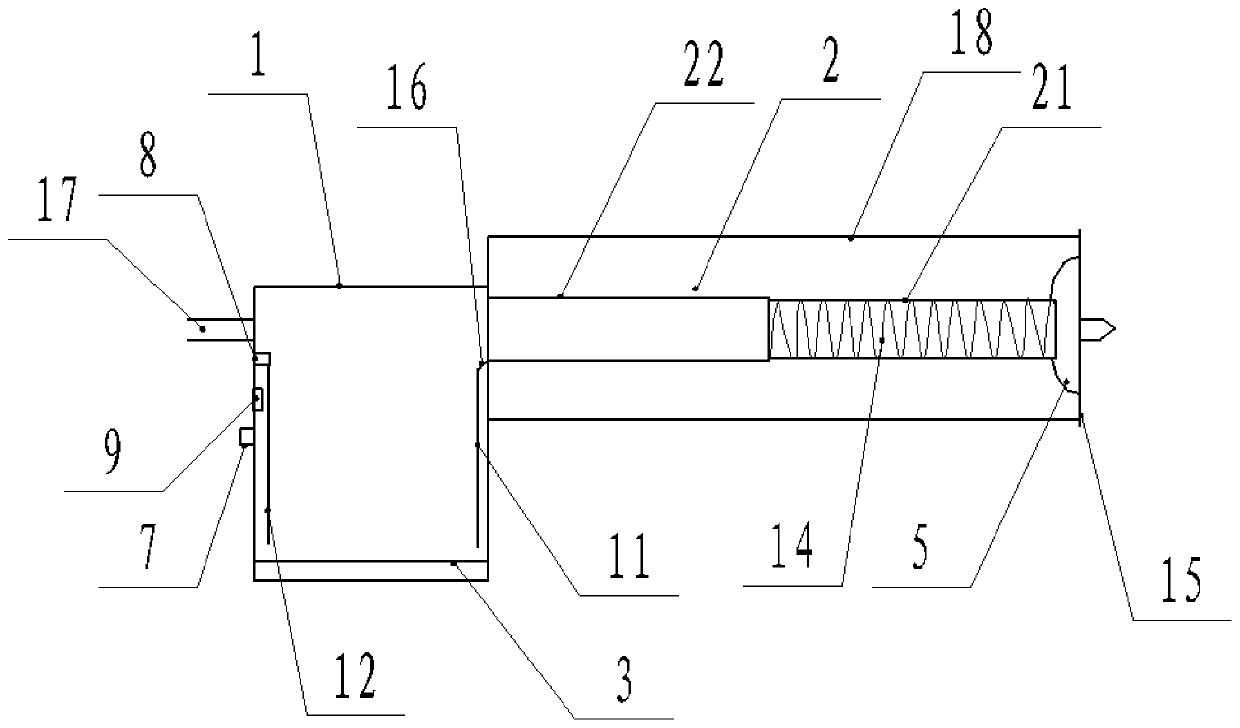

[0033] Such as Figure 1-Figure 3As shown, the embodiment of the present invention is a dust collection device for electric tools, including a dust collection box 1 (the dust collection box 1 is an insulator), connected to the air inlet (not shown in the figure) of the dust collection box 1 The dust suction pipe 2 and the first filter screen 3 arranged in the dust collection box 1 and away from the end of the dust suction pipe 2, the periphery of the first filter screen 3 abuts against the inner wall of the dust collection box 1 An air outlet 4 is opened at one end of the dust collecting box 1 corresponding to the first filter 3 . The nozzle periphery of the end of the dust collection pipe 2 away from the dust collection box 1 is also connected with a dust collection cover 5 with an inner diameter larger than the outer diameter of the nozzle, and the dust collection cover 5 passes through the end far away from the dust collection pipe 2. A cross bar is fixed with fan 6 for su...

Embodiment 2

[0049] This embodiment is the same as that of Embodiment 1 except that the weight composition of the noise reduction material and its preparation method are different from Embodiment 1.

[0050] The noise reduction material in the noise reduction box 18 in this embodiment is mainly made of the following raw materials in parts by weight: 40 parts of rice bran, 30 parts of polyester fiber sound-absorbing cotton, 20 parts of white vermiculite powder, 20 parts of sepiolite powder, light 20 parts of calcium carbonate, 20 parts of glass fiber, 10 parts of mesoporous titanium dioxide, 10 parts of neoprene, 10 parts of polycarbonate and 8 parts of alkyd resin.

[0051] The preparation method of the above-mentioned noise reduction material comprises the following steps:

[0052] (1) Take the above-mentioned raw materials in parts by weight;

[0053] (2) After mixing rice bran, polyester fiber sound-absorbing cotton, white vermiculite powder, sepiolite powder and light calcium carbonat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com